Last Updated on April 19, 2023

Installing a water pressure regulator is about getting the perfect amount of water in your plumbing system, so you naturally want to ensure it’s done just right.

You might have noticed most regulators are installed horizontally, but can a water pressure regulator be installed vertically?

While it is indeed possible to install a water pressure regulator in either a horizontal or vertical orientation, opting for a horizontal installation is highly recommended.

The primary reason for this preference lies in the effectiveness of debris collection. A vertical installation may hinder the strainer’s ability to perform its duties effectively.

Consequently, debris accumulates between the valve’s seat and the valve itself. This scenario can lead to leakage and expedited wear on the valve seat, eventually reducing the regulator’s overall lifespan and performance.

Let’s dive in and see what issues you may face when mounting a water pressure regulator vertically, explore solutions to these problems, plus uncover why it might be wiser overall to install the regulator horizontally. Ready? Read on.

Can a Water Pressure Regulator Be Installed Vertically: What Problems?

If you think setting up a water pressure regulator is as easy as setting it up vertically, think again. This setup can bring some unwelcome surprises.

So if you’re looking to get the most out of your system, account for any hidden headaches that may come with vertical positioning. The following are some potential arising issues:

1. Strainer Placement

When you install a water pressure regulator, it is crucial to ensure proper strainer placement. Typically, the strainer is positioned at the bottom of the valve to filter out any debris carried by the water flow effectively.

Vertically attaching a water pressure regulator can compromise this essential function. The result is poor filtration and containment of debris, which can subsequently get lodged between the valve seat and the water pressure regulator.

This affects the functionality and efficiency of the water pressure regulator, leading to potential performance issues and failures.

2. Debris Collection and Containment

In a vertical installation, the strainer may fail to collect and contain debris effectively, allowing it to enter the check valve mechanism. This can, in turn, lead to damage and accelerated wear on the valve components.

Debris entering the valve can also cause the internal mechanisms to malfunction, leading to poor performance of the regulator.

Over time, the uncontained debris can cause the valve to wear down, increasing the chances of leakage and reducing the overall service life of the regulator.

3. Leakage

Leakage is a major concern when debris passes the strainer and into the valve of a vertically installed regulator.

Since the strainer cannot effectively capture and contain debris in this orientation, particles can settle into the valve seat and the moving parts of the regulator. This can lead to an improper seal, resulting in leaks and compromised performance.

Leakage wastes water and can lead to bigger issues, such as damage to other components of a plumbing system, structural damage, or even mold growth.

In the long run, the wear and tear caused by leaks may require costly repairs and replacement parts or even the entire water pressure regulator.

4. Valve Wear and Tear

The continuous presence of debris in the valve mechanism of a vertically mounted pressure regulator can cause significant wear and tear on the internal components.

This includes the wearing down of the valve seat, seals, and other moving parts, which reduces their effectiveness and efficiency.

Valve wear and tear can ultimately reduce the operational life of the water pressure regulator and necessitate repairs or replacements more frequently.

As the wear continues unchecked, the regulator may become unable to maintain proper water pressure or shut off completely, leading to potential flooding, water damage, and expensive repair costs.

Solutions to Issues Arising From Water Pressure Regulator Vertical Installation

You have plenty of options to deal with potential issues from the vertical installation of a water pressure regulator. These include:

1. Sediment Filter Installation

Installing a sediment filter on your water service line effectively reduces issues arising from vertical water pressure regulator installations.

Sediment filters work by trapping particles such as sand, rust, and silt that are present in the water supply.

These particles can cause damage to the internal components, resulting in decreased performance or even valve failure.

To ensure the effective functioning of a sediment filter, proper installation and regular maintenance are essential.

Choose a filter with a micron rating suitable for your water supply quality, as this will effectively filter out the specific types and sizes of debris present.

Installing the sediment filter close to the water pressure regulator valve is important to prevent premature valve wear.

Additionally, regularly check the sediment filter for accumulated debris and replace the filter cartridge as needed.

Installing a filter with a clear housing can make it easier to visually inspect the filter and determine when it’s time to replace the cartridge.

2. Regular Maintenance and Cleaning

To ensure that the valve is functioning properly over time, regular maintenance and cleaning are essential. This can include checking for any blockages or wear and tear on the valve, cleaning any strainers, adjusting pressure settings, and inspecting for any signs of damage.

It is also essential to be mindful of how often these tasks are performed. Typically they should be done at least once per year or whenever necessary due to changes in pressure or other factors.

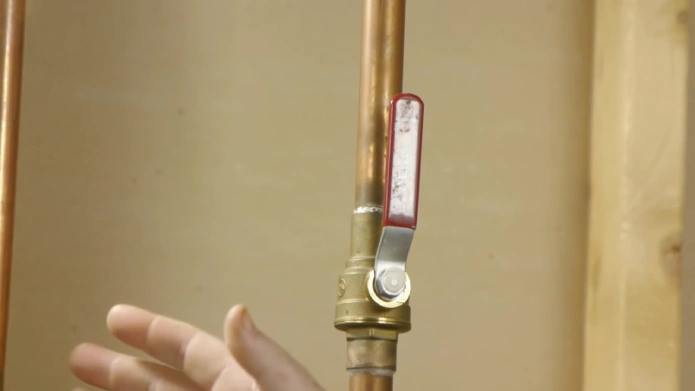

3. Proper Installation Orientation

Although the vertical installation may sometimes be unavoidable due to space constraints or existing plumbing configurations, it is generally recommended to install water pressure regulators horizontally.

Horizontal installation can help alleviate issues associated with debris entry and wear and tear on the water pressure regulator valve.

When installing a pressure regulator valve horizontally, it is crucial to position the valve with the arrow pointing toward the water flow. This ensures the valve operates correctly and maintains the desired water pressure throughout the system.

Will a Vertically Installed Water Pressure Regulator Affect Its Functionality?

A vertically attached water pressure regulator will still operate effectively, maintaining consistent water pressure throughout the system.

However, the vertical positioning may lead to faster wear and tear on the regulator’s components, resulting in a need for more frequent maintenance and possible replacement over time.

Regular inspection and timely servicing of the regulator are recommended for vertically installed units to ensure optimal performance and longevity.

Is It Possible to Repair a Water Pressure Regulator, Or Do I Have to Replace It?

In many instances, addressing issues with a water pressure regulator and bringing it back to its optimal performance levels is possible. The feasibility of such repairs largely hinges on the damage’s severity and the device’s overall condition.

For minor hiccups, a skilled technician may be able to perform the necessary adjustments or part replacements to restore the regulator to its intended function.

However, in cases where the regulator has experienced substantial damage or has simply reached the end of its operational life cycle, it becomes prudent to consider investing in a new, more efficient replacement.

Maximize Your Water Pressure Regulator’s Performance – Install Horizontally

If you want to get the most from your water pressure regulator, then it’s essential that you install it horizontally. This ensures optimal performance and long-lasting use as debris collects away efficiently, ensuring nothing interferes with its functioning.

This will help prevent valve leakage through its seat and premature wearing out of the same. Therefore, if you’re considering adding a water pressure regulator at home, make sure you do so horizontally for maximum efficiency and durability.