Last Updated on May 29, 2023

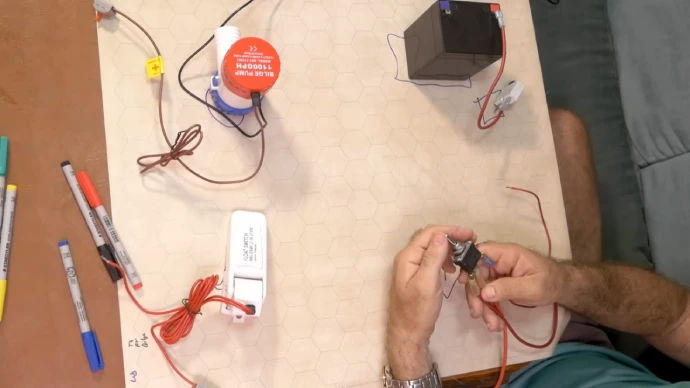

Looking for a durable and trustworthy bilge pump for home plumbing or indoor and outdoor water applications? Don’t overlook the importance of selecting the right fuse size for optimal performance and safety. A minor oversight in this crucial detail could lead to fire hazards and other serious issues.

Now the question is, what size fuse for the bilge pump? Let us help you make the right choice. Generally, a 12-volt 5-amp bilge pump will require a 7.5 or 10-amp fuse to function optimally.

Should you have a 12-volt 10-amp pump? A standard 15-amp fuse on the power input side will sufficiently manage both the circuit wire and the bilge pump. It is always advisable to follow the manufacturers’ recommendations.

This blog will explore the factors to consider when achieving the correct fuse size for your bilge pump, ensuring safe and dependable use. So stay tuned and read on to learn more.

What Size Fuse for Bilge Pump: Factors to Consider

The type and size of fuse you select for your bilge pump will depend on the voltage, power rating and amperage draw. To ensure safe operation, keep these factors in mind when determining what size fuse is best:

No 01: Amperage Rating

When determining the appropriate fuse size for your bilge pump, it is essential to consider the pump’s amperage rating.

The amperage rating can be found in the pump’s specifications, and the fuse selected should be slightly higher than the pump’s maximum amperage draw. This ensures the fuse can handle the current flowing through it without blowing or melting due to electrical overload.

Fuse sizes that are too small can blow or melt, causing the pump to stop functioning. Therefore, selecting a fuse with an amperage rating that matches the pump’s maximum amperage draw is crucial.

No 02: Wire Gauge

The wire gauge that connects the bilge pump to the battery or electrical panel is another essential factor to consider when selecting the fuse size. The wire gauge must be appropriate for the pump’s amperage draw to prevent excessive resistance, which can cause overheating or draw too much current.

Consult a wire sizing chart to determine the appropriate wire gauge for your pump’s amperage draw. Be sure to select a fuse that matches your pump’s wire gauge and amperage draw to ensure proper functionality.

No 03: Type of Fuse

There are different fuses, including blade fuses, glass tube fuses, and circuit breakers. Blade fuses are the most common type used in household water lines and come in various amperage ratings. Glass tube fuses are less common and may be used when space is limited.

Circuit breakers are an alternative to fuses and can be reset if they trip. When selecting a fuse type, consider the amperage rating and size of the pump, as well as the ease of replacement and accessibility. Select a fuse type that best suits your needs.

No 04: Voltage Rating

The fuse you select should have a voltage rating that matches the voltage of your pump. If the voltage rating is too low, it can cause the fuse to blow. Most ones have a 12-volt electrical system. The fuse you select must have the correct voltage rating to prevent damage or malfunction of your pump.

No 05: Other Electrical Components

If your bilge pump is connected to other electrical components, such as a battery switch or control panel, you should consider the amperage draw of all the components together.

Combining the components’ amperage ratings will ensure that the fuse you choose can handle the total amperage draw of the entire system. Select a fuse that can handle all components’ combined amperage draw.

No 06: Environmental Conditions

The location of the bilge pump and the conditions it will be exposed to should also be considered when selecting the correct fuse size. The pump may be exposed to salt water or other corrosive substances, so a marine-grade coating or a waterproof fuse holder may be necessary.

Also, if the pump is exposed to extreme temperatures or high vibration levels, select a fuse that can withstand these conditions. Consider the environmental conditions when choosing the appropriate fuse size.

What amp fuse for the dual bilge pump?

The appropriate amp fuse for a dual bilge pump depends on the amperage rating of the pumps.

To determine the correct fuse size for your dual bilge pump, add both pumps’ amperage and choose a fuse size slightly higher than the total amperage.

For example, if each pump has a 5-amp rating, the total amperage for both pumps would be 10 amps. You would want to select a slightly higher fuse, such as a 15-amp or 20-amp fuse, to ensure it can handle the current draw of both pumps without blowing.

It is important to note that using the correct fuse size is crucial for safety, as it protects the wiring and electrical components from overheating and potential fires.

And it is always recommended to consult the manufacturer’s instructions or a qualified marine electrician for specific recommendations for your bilge pump setup.

What happens if the wrong size fuse is used for a bilge pump?

Using the wrong size fuse for a bilge pump can have several consequences, depending on the circumstances.

If the fuse is too small, it may blow frequently or even immediately upon starting the pump. It may result in the pump not functioning at all, preventing water from being pumped from the bilge and potentially causing water to be used by applications.

And if the fuse is too large, it could allow too much current to flow through the circuit, which could overload and damage the pump or other components in the circuit. This could cause a fire or other safety hazard in extreme cases.

It’s important to always use the correct size fuse for any electrical equipment, including bilge pumps. The correct fuse size should be specified in the pump’s documentation or on its label and should match the ampere rating of the pump or the circuit it is connected to.

How often should you check the fuse for your bilge pump?

Inspecting the fuse for your indoor or outdoor bilge pump at least once a year or whenever you perform routine maintenance on your home’s water system is recommended.

Checking the fuse ensures that it is in good working condition and will be able to protect your bilge pump and wiring from electrical damage in case of a short circuit or overload.

But, if you notice any issues with your bilge pump or its electrical system, such as a blown fuse, tripped circuit breaker, or erratic pump behavior, you should investigate the problem immediately and check the fuse as part of your troubleshooting process.

It’s better to be proactive in checking and replacing fuses to prevent potential damage to your pump or its power systems like solar panels or batteries.

Safeguard Your Bilge Pump with the Right Fuse Size

When it comes to ensuring the correct functioning of your bilge pump, selecting the appropriate fuse size is a critical step for both indoor and outdoor water applications at home.

Professionals suggest using either a 7.5-amp or a 10-amp fuse for equipment that requires a maximum amperage draw of 12 volts and five amps. But, for equipment with more considerable power demands, such as 12 volts and ten amps, installing a 15-amp fuse in the panel is essential.

The safety of your system should be your top priority, and selecting the proper fuse size can prevent major risks and potential damages. Don’t leave anything to chance with electrical equipment; always err on the side of caution and ensure safety first.