Last Updated on June 13, 2025

You get pinhole leaks in copper plumbing mainly because corrosive water chemistry and aging pipes accelerate internal corrosion.

Acidic or hard water, plus disinfectants like chloramines, break down protective oxide layers, causing pitting and metal loss. Temperature fluctuations and turbulent flow worsen this by stressing and eroding pipe walls.

External factors like soil conditions and stray currents can also damage pipes. Understanding these causes helps you prevent leaks and protect your plumbing system’s longevity.

Key Takeaways

- Acidic water and chloramines chemically attack copper pipes, causing internal pitting that leads to pinhole leaks.

- High water velocity and turbulent flow strip protective oxide layers, accelerating erosion-corrosion and leak formation.

- Temperature fluctuations induce thermal stress and microfractures, weakening pipe walls over time.

- Mineral deposits from hard water promote localized corrosion and create conditions for pinhole leaks.

- External factors like soil moisture, stray electrical currents, and mechanical stress contribute to copper pipe corrosion and leaks.

The Role of Water Chemistry in Copper Pipe Corrosion

Because water chemistry directly influences the interactions between water and copper pipes, understanding its role is essential to diagnosing and preventing corrosion. You must consider factors like ion concentration, water temperature, and pH to assess corrosion risk accurately.

The choice of pump type, such as submersible pumps, can affect water temperature and flow, indirectly impacting corrosion rates in plumbing systems.

Water chemistry governs copper pipe corrosion; ion levels, temperature, and pH are key factors to monitor.

Calcium and magnesium ions promote limescale formation, which narrows pipe diameter, increases water velocity, and accelerates corrosion. Soft water, lacking these ions, paradoxically increases general corrosion rates.

Water temperature intensifies erosion corrosion by boosting reaction kinetics. Elevated temperatures can accelerate corrosion processes, leading to faster pipe degradation.

pH plays a critical role: neutral pH stabilizes protective oxide layers on copper surfaces, while acidic or highly alkaline conditions accelerate corrosion. Additionally, oxygen levels affect oxidation reactions, influencing corrosion rates by forming copper oxides and differential aeration cells.

Effects of Acidic and Hard Water on Copper Plumbing

Water chemistry parameters such as pH and mineral content directly influence copper pipe integrity, making the impacts of acidic and hard water particularly significant.

Acidic water, with pH below 7.0, aggressively corrodes copper pipes through direct chemical attack, causing copper leaching, blue-green staining, and accelerating pinhole leak formation.

Elevated dissolved carbon dioxide and organic acids intensify this corrosion, reducing appliance lifespan and imparting a metallic taste.

Conversely, hard water contains high calcium and magnesium levels, promoting mineral scaling and increased total dissolved solids that elevate electrical conductivity, indirectly fostering corrosion.

This scaling can restrict flow and raise pressure within pipes. While hard water minerals sometimes act as corrosion inhibitors, the resultant mineral buildup still compromises plumbing efficiency.

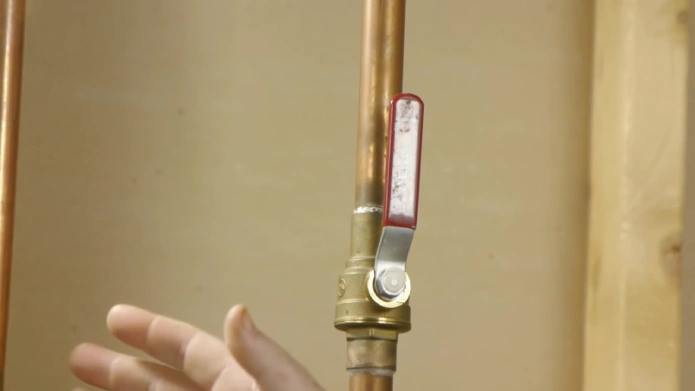

Understanding these mechanisms is vital for diagnosing and mitigating copper pipe degradation in various water chemistries. Regular maintenance and monitoring valve response can help prevent serious plumbing issues related to pinhole leaks.

Impact of Disinfectants and Treatment Chemicals on Copper Pipes

You’ll find that chloramines, while less aggressive than free chlorine, still contribute to copper corrosion and pinhole leaks over time. When water treatment methods shift, these changes can alter disinfectant chemistry and accelerate pipe degradation.

Using chemical-resistant materials in plumbing systems can help mitigate these effects. Understanding how these factors interact is essential for managing corrosion risks in copper plumbing.

Chloramines and Corrosion

Although chloramine serves as a stable and effective disinfectant in water treatment, it plays a significant role in accelerating corrosion and pitting in copper plumbing systems.

When chloramine interacts chemically with copper, it disrupts protective oxide layers, causing copper oxidation and the release of copper ions. This accelerates localized pitting, leading to microscopic pinholes that expand into leaks.

You should be aware that chloramine-induced corrosion:

- Creates aggressive chemical environments more damaging than chlorine alone

- Produces hydrogen gas internally, further increasing corrosion rates

- Causes premature pipe failures, sometimes within two years

- Complicates detection due to sporadic, widespread pinhole leaks

Regular maintenance and monitoring water quality can help mitigate these corrosion effects. Additionally, corrosion from chloramine can lead to contamination with metals such as lead, zinc, and copper, posing further health risks.

Understanding chloramine’s corrosive mechanisms is critical for managing risks and preserving your copper plumbing infrastructure.

Treatment Changes Effects

Chloramine’s role in accelerating copper corrosion highlights the broader impact that changes in water treatment chemicals can have on plumbing systems. When you switch disinfectants, such as from chlorine to chloramines, you alter the chemical environment inside copper pipes.

Studies show that disinfectant residuals significantly shape bacterial community composition, with chlorine treatments linked to higher activity of opportunistic pathogens like Legionella spp. Selecting water heaters with appropriate materials can reduce corrosion risks in these environments.

Chlorine, while more potent, can aggressively react with copper, accelerating corrosion especially in stagnant water. Chloramines, though more stable, reduce disinfectant efficacy and may increase microbial risks like mycobacteria growth.

Proper temperature control in water systems can mitigate some of these microbial risks and corrosion effects. Additionally, factors like pH, oxygen, temperature, and water hardness interact with these chemicals, influencing corrosion rates.

Secondary disinfectants and dosed copper ions further complicate this balance by affecting biofilm formation and pathogen control. Monitoring and maintaining energy-efficient water heaters can help maintain stable water temperatures and reduce corrosion.

Therefore, understanding the precise chemical interactions and treatment impacts is critical to mitigate pinhole leaks and preserve copper pipe integrity. Implementing regular maintenance and professional inspections of water heating systems ensures longevity and reliability in commercial plumbing setups.

How Internal Corrosion Leads to Pinhole Leaks?

When internal corrosion attacks copper plumbing, it initiates microscopic damage that gradually develops into pinhole leaks. This corrosion often manifests as pitted corrosion, where localized damage erodes the pipe’s inner surface.

Proper maintenance and inspection can help identify early signs of corrosion before leaks develop. Chemical agents like chlorine accelerate this process, while galvanic corrosion occurs when copper contacts other metals, generating electrical currents that hasten deterioration.

Water chemistry also plays a critical role; both acidic and basic pH values contribute to corrosion, and elevated mineral content intensifies the damage. Additionally, hard water increases mineral deposits, promoting corrosion inside the pipes.

You should recognize key factors that exacerbate internal corrosion:

- Chlorine presence in water speeds up chemical corrosion

- High water velocity increases mechanical wear on copper

- Temperature gradients cause uneven corrosion rates

- Aluminum compounds, often from treatment, amplify corrosion risk

Understanding these mechanisms helps prevent costly pinhole leaks, and following proper disassembly procedures can aid in inspecting and maintaining plumbing components effectively.

External Environmental Factors Contributing to Copper Pipe Damage

Since copper pipes are often buried or enclosed within structures, external environmental factors play a crucial role in their longevity and integrity. Soil composition, moisture, and chemical contaminants like ammonia from animal waste accelerate external corrosion, promoting pinhole formation.

Soil, moisture, and contaminants like ammonia accelerate copper pipe corrosion and promote pinhole leaks.

Mechanical stresses from soil movement, tight pass-throughs, and environmental vibrations induce fatigue and microfracture.

Atmospheric moisture and condensation further exacerbate oxidative corrosion, especially when combined with deteriorated pipe coatings or incompatible insulation materials.

Copper pipes are common due to historical use and durability, but pose health and environmental risks, which makes understanding and mitigating these external factors critical. Protective measures similar to those used in galvanized pipe corrosion prevention can help extend pipe life.

Geological activity, such as earthquakes, imposes sudden severe stresses causing cracks and fractures, increasing failure risk. Temperature fluctuations cause expansion and contraction cycles that weaken pipe walls over time.

Additionally, exposure to environmental chemicals and abrasive particles can erode copper surfaces externally, increasing permeability and leak susceptibility. Understanding these factors is essential to preventing premature copper pipe damage.

Electrical and Mechanical Causes of Accelerated Corrosion

Although external factors considerably impact copper pipe integrity, electrical and mechanical causes often accelerate corrosion more rapidly and insidiously.

Stray electrical currents, frequently stemming from poor grounding or lightning strikes, drive electrochemical reactions that deteriorate copper surfaces. Proper grounding directly to a copper rod driven into the earth is essential to prevent these damaging electrical currents.

Additionally, improper installation can lead to increased mechanical stresses that compromise pipe durability through shaft vibration. Mechanical stresses from improper installation or high water velocity exacerbate physical wear and erosion-corrosion.

Understanding these factors is vital for effective prevention. Key contributors include:

- Stray electrical currents from grounding issues or appliance electrolysis

- Contact between copper and dissimilar metals causing electrolytic corrosion

- High water velocity inducing erosion-corrosion, especially in hot water systems

- Sediment or grit physically abrading pipe interiors

Identifying Early Signs of Pinhole Leaks in Copper Plumbing

You should inspect copper pipes for visual leak indicators like blue-green stains and white mineral deposits, which signal early corrosion. Pay close attention to unusual water stains on surrounding surfaces, as they often reveal hidden leaks.

Regular inspection and maintenance of plumbing valves can help prevent further damage. Detecting moisture patches near joints or along pipe runs is critical for early identification and prompt repair.

If you notice a sudden drop in water pressure, it may indicate a pinhole leak in your copper plumbing system.

Visual Leak Indicators

A clear understanding of visual leak indicators is essential for identifying early signs of pinhole leaks in copper plumbing. Early detection helps prevent extensive damage and costly repairs.

You should regularly inspect your copper pipes and surrounding areas for specific signs that reveal leaks:

- Blue-green discoloration on copper pipes, signaling corrosion.

- Visible water droplets forming on pipes or nearby surfaces.

- Mold or mildew growth with associated musty odors.

- Persistent water spots on walls or ceilings, unaffected by water usage. Monitoring for these signs is crucial because continuous water exposure accelerates corrosion and leak development. Installing pipes in areas with proper ventilation requirements can help reduce moisture buildup that promotes corrosion.

Unusual Water Stains

When copper pipes develop pinhole leaks, unusual water stains often appear on walls or ceilings near the affected area. These stains typically manifest as discolored patches, ranging from yellowish to brown, caused by water escaping through microscopic holes and seeping into surrounding materials.

You should monitor these stains closely, as they indicate ongoing corrosion within the pipes, often accelerated by factors like high chlorine levels or rust particles from water heaters. This corrosion is a specific type known as formicary corrosion, which creates tiny pits that eventually lead to leaks.

Early identification of these discolorations can prevent extensive structural damage and mold growth. Addressing these stains promptly by inspecting the underlying plumbing is essential.

Ignoring them risks escalating water damage and costly repairs. Regular maintenance and water quality management can mitigate corrosion, reducing the likelihood of pinhole leaks and associated staining.

Detecting Moisture Patches

Although moisture patches may initially seem inconspicuous, they serve as critical indicators of potential pinhole leaks in copper plumbing. Early detection hinges on your ability to identify subtle signs before extensive damage occurs.

Focus your inspection on key areas where leaks manifest:

- Visual moisture on walls and floors, including dampness or pooling water

- Greenish-blue discoloration caused by copper oxidation around affected areas

- Warped flooring or raised tiles signaling subsurface water intrusion

- Patterns of moisture trails leading to specific leak sources

Using visual inspection regularly helps catch these early signs before they worsen.

The Influence of Pipe Age and Temperature Fluctuations on Leak Formation

Since copper pipes degrade over time, you’ll find that their susceptibility to pinhole leaks increases considerably with age, especially under fluctuating temperature conditions.

Copper pipes become increasingly vulnerable to pinhole leaks as they age, particularly with temperature changes.

As pipes age, internal pitting corrosion weakens structural integrity, making them prone to failure at minor corrosion sites. Temperature fluctuations exacerbate this by inducing expansion and contraction, creating microfractures and stress points.

These cycles destabilize copper’s protective oxide layer, accelerating corrosion rates. Older pipes exposed to repeated thermal cycling experience faster pit growth, which breaches pipe walls more rapidly.

Additionally, temperature changes alter water chemistry, intensifying corrosive effects on compromised pipes. Moreover, the presence of chloramines in water significantly increases internal pipe damage risks, further contributing to corrosion.

Understanding this synergy is essential, as it highlights why aging copper plumbing in environments with frequent temperature swings demands vigilant maintenance to mitigate the heightened risk of pinhole leak formation.

The Role of Water Turbulence and Flow in Corrosion Development

Because turbulent water flow disrupts the protective corrosion layers on copper pipes, it considerably accelerates erosion corrosion, especially in hot water recirculation systems.

You’ll find that high turbulence not only strips away corrosion product layers but also increases mechanical wear through elevated fluid velocity and impingement forces. This exposes fresh metal surfaces, making them vulnerable to localized attack.

Additionally, turbulent conditions foster concentration cell corrosion by creating micro-environments with variable oxygen or ion concentrations. Key factors to consider include:

- Velocity-induced corrosion at flow rates exceeding 17.5 ft/sec

- Cavitation events removing protective scales

- Synergistic effects of turbulence and corrosive water chemistry

- Flow-driven concentration cells accelerating localized metal loss

Preventative Measures to Minimize Pinhole Leak Risks in Copper Pipes

When you manage water quality effectively and maintain your copper plumbing system regularly, you considerably reduce the risk of pinhole leaks.

Start by installing water softeners and filtration systems to minimize mineral buildup and remove corrosive particles. Introducing sacrificial additives such as Parafos can also sequester oxygen inside pipes, preventing oxygen corrosion.

Monitor and adjust water pH to maintain levels between 6.5 and 8.5, preventing corrosive conditions. Employ corrosion inhibitors compatible with copper to form protective films inside pipes. Schedule professional inspections annually or bi-annually, focusing on older pipes and leak-prone areas.

Conduct pressure and visual tests to detect early corrosion. Control water pressure with reducing valves and surge suppressors to prevent mechanical stress. For aging systems, consider targeted repiping or upgrading to corrosion-resistant materials like PEX, following current codes.

Frequently Asked Questions

Can Water Softeners Prevent Pinhole Leaks in Copper Pipes?

You can use water softeners to reduce pinhole leak risks by lowering calcium and magnesium levels that contribute to scale and corrosion. However, they don’t guarantee prevention since other factors like chloride content, pH, and water velocity also play significant roles.

You’ll need a thorough water chemistry analysis and possibly additional treatments or pipe maintenance to effectively protect copper pipes from pinhole leaks. Softeners are helpful but not a standalone solution.

Do Pinhole Leaks Affect Both Hot and Cold Water Lines Equally?

You notice leaks in hot pipes, you notice leaks in cold pipes, and you wonder if pinhole leaks affect both equally. They don’t.

Hot water lines often face accelerated corrosion due to heat and chemical reactions, causing more rapid leaks. Cold water pipes see different corrosion types influenced by water chemistry and pH.

Is Copper Pipe Thickness a Factor in Leak Susceptibility?

You shouldn’t rely on copper pipe thickness alone to gauge leak susceptibility. Studies show no direct correlation between wall thickness and the time to repair small leaks. Instead, factors like corrosion, water chemistry, and manufacturing defects play bigger roles.

While thicker pipes might seem sturdier, corrosion and material imperfections undermine their integrity regardless of thickness. Focus on proper installation and water quality control to minimize leak risks effectively.

How Does Pipe Insulation Influence External Copper Corrosion?

You need to guarantee pipe insulation prevents moisture accumulation because trapped moisture between copper pipes and insulation fosters external corrosion. If insulation isn’t sealed properly, condensate forms, creating a wet environment that accelerates corrosion.

Thermal cycling and temperature gradients caused by insulation imperfections also promote localized corrosion. Using vapor barriers and corrosion-resistant materials correctly helps reduce this risk.

Are Copper Pipe Warranties Voided by Pinhole Leak Damage?

Did you know copper pipes expected to last 20-50 years can develop pinhole leaks within just a few years? Your warranty may be voided if these leaks result from improper installation, poor maintenance, or external factors like water chemistry changes.

Insurers and manufacturers often exclude damage caused by electrolysis or corrosion due to neglect. Always review your warranty terms carefully and document maintenance to protect your coverage rights.

Preventing the Problem: What You Can Do to Protect Your Plumbing?

Just like a skilled detective spots subtle clues before a mystery unfolds, you can identify early signs of pinhole leaks and act swiftly to protect your copper plumbing. Understanding water chemistry, environmental factors, and corrosion mechanisms empowers you to prevent costly damage.

By controlling water quality, minimizing turbulence, and monitoring pipe conditions, you’ll extend your system’s life, turning potential leaks from hidden threats into manageable challenges you confidently handle.