Last Updated on May 16, 2023

The fluid or gas will flow out of the faucet at full force without any pressure controller. This can quickly lead to problems such as burst pipes or broken fixtures. High pressure can sometimes cause the liquid or gas to back up, leading to disaster.

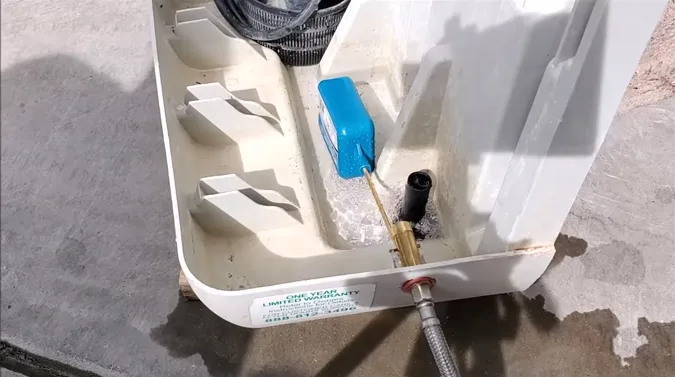

So, you must install a pressure controller such as a pressure reducing valve or pressure regulator to avoid these costly and inconvenient problems. Pressure-reducing valves reduce or limit downstream pressure when the upstream pressure is variable and/or unknown.

Conversely, pressure regulators maintain constant upstream pressure. Often, both devices can be used in tandem (arranged one in front of the other) to provide stability to a system with variable upstream and downstream pressures.

Please continue reading to determine how to optimize your system by understanding the differences between these two devices and how they work.

Differences Between Pressure Reducing Valve & Pressure Regulator

Though both pressure control valves do the job of controlling or moderating the flow of a fluid, there are distinct differences between the two devices:

Working Procedure

A PRV controls fluid flow by reducing or limiting the pressure of a liquid or gas, while a pressure regulator controls fluid flow by maintaining constant outlet pressure despite changes in inlet pressure or flow rate.

This is because a PRV has a higher pressure set-point than the inlet pressure, while a pressure regulator maintains the same outlet pressure regardless of changes in the inlet or outlet flow.

Working Accuracy

Pressure regulators are widely recognized for their high levels of accuracy. These devices are designed to maintain a constant pressure output regardless of fluctuations in the fluid supply.

Conversely, pressure-reducing valves are less accurate than pressure regulators. These devices are designed to reduce or limit the fluid pressure from high inlet pressure to lower outlet pressure.

Working Components

PRVs are typically used with liquid-filled systems, such as water lines and oil lines, while pressure regulators are more often used with gas-filled systems, such as propane tanks and natural gas lines.

Working Demand

A pressure reducing regulator controls outlet pressure by bleeder orifice. This type of valve is used when the desired outlet pressure is lower than the inlet pressure, which causes the overall pressure to drop to the desired level.

Pressure-reducing valves control inlet pressure by an adjustable spring force. These valves are used for outlets with pressures higher than the inlet pressure. They work by using an adjustable spring force to control the inlet pressure.

Working Direction

Pressure regulators are unidirectional, while pressure reducing valves are bidirectional. Pressure regulator unidirectional valves allow fluid to flow in both directions by automatically opening and closing. This maintains a constant flow rate through the valve, regardless of changes in demand downstream.

In contrast, PRVs are bidirectional devices that reduce the pressure of a fluid passing through them to a preset level. This can be accomplished by either throttling the flow or completely shutting it off.

PRVs are typically used in applications where it is necessary to protect downstream equipment from high pressures, such as domestic water systems.

Working Diaphragm

Pressure regulators have a seat and a diaphragm, while pressure-reducing valves only have a diaphragm. The seat provides a physical barrier the diaphragm must push against to open the valve. This design protects the diaphragm from being damaged by high-pressure fluids on the upstream side of the valve.

Meanwhile, the diaphragm in a pressure relief valve is directly exposed to high-pressure fluids. Although this allows for faster response times and better flow control, the diaphragm is more prone to damage if the valve is exposed to high-pressure fluids.

Construction Material

The construction material for pressure regulators and PRVs is vitally important. Common materials include brass, bronze, stainless steel, and plastic. Each material has its own advantages and disadvantages, depending on the application.

For example, brass is an excellent choice for high-temperature applications, while stainless steel is better suited for beverage processing applications. Plastic is often used in low-pressure applications where weight and cost are significant concerns.

As you can see, there are several vital ways pressure reducing valves and pressure regulators differ. Keep these differences in mind the next time you need to select a valve for your application.

Pricing

Regarding price, pressure-reducing valves are typically more affordable than pressure regulators. This is because pressure-reducing valves are designed to meet the needs of a broader range of applications, making them more cost-effective and widely accessible.

Meanwhile, pressure regulators are precision instruments that require a higher level of engineering and manufacturing, which tends to increase their costs.

Can a Pressure Regulator be Used for a Long Time?

Depending on the application, a pressure regulator can be used for a lengthy period. For example, if you have a water pressure regulator on your home’s main water line, it can last for years.

Due to an air compressor’s high temperatures and pressures, a pressure regulator must be replaced more often. Generally, pressure regulators last long if they are well-maintained and used correctly. Replacement parts are also readily available should something wear out prematurely.

How Long Does a Pressure Regulator Last?

Pressure regulators are expected to last for at least four to five years, but as they age, they can become clogged with sediment or debris, which may shorten their lifespan. They may be damaged when water pressures are high or temperatures below freezing.

To ensure that your pressure regulator is functioning properly, you must check it regularly. Select a reputable brand that offers a warranty when replacing your pressure regulator.

Are There Any Limitations to the Pressure Regulator?

There are three main limitations to keep in mind: blockages, damage to internal components, and incorrect pressure settings. Let’s take a closer look at each one.

One of the most common problems with pressure regulators is blockages. This can be caused by anything from organic matter to corrosive substances. If a blockage occurs, it can restrict fluid flow and prevent the regulator from working properly.

It is also possible for the pressure regulator to be damaged internally, leading to leakage. Generally, many leaks are caused by internal components deterioration (such as gaskets). These gaskets form an air-tight barrier between the regulator’s metallic parts. If the damage is severe enough, the regulator can fail completely.

Another common issue is incorrect pressure settings. This can happen if the regulator needs to be calibrated correctly or the wrong setting is used for the specific application. If this happens, it can result in poor performance or even complete failure of the regulator.

While these are some of the most common pressure regulator problems, it’s important to remember that they are not the only ones. Always consult your owner’s manual for more information on troubleshooting and maintaining your pressure regulator.

How to Find a Quality Water Pressure-Reducing Valve?

High water pressure can damage pipes, appliances, and fixtures. Fortunately, a quality water pressure-reducing valve can reduce the high pressure and help you achieve the ideal pressure balance. Here are some tips for finding a quality one:

Multiple Pressure Settings

When searching for a water pressure-reducing valve, it’s essential to find one that offers multiple pressure settings. This feature allows you to adjust the water pressure according to your needs, whether for different appliances or personal preferences.

A PRV with multiple settings offers flexibility and convenience, giving you greater control over your home’s water supply. Look for valves that offer a range of settings, from very low to high pressure, to find the perfect balance for your needs.

Adjustable Pressure Knob

An adjustable pressure knob is another critical factor when choosing a water pressure-reducing valve. This knob lets you fine-tune the water pressure to suit your needs and prevent damage to your pipes and appliances.

A high-quality valve with an adjustable knob ensures you can quickly adjust the pressure to suit your preferences and avoid costly repairs in the long run. When searching for a valve, look for one with an easy-to-use knob that provides smooth and precise adjustments.

Rust Resistance

Water is essential for life but can also be detrimental to metal if left untreated. For this reason, choosing a water pressure-reducing valve that is rust-resistant is critical. A valve made of high-quality, corrosion-resistant materials can save you headaches and money in the long run.

Look for valves with sturdy and long-lasting brass or stainless steel for optimal rust resistance. Also, PRVs coated with an anti-corrosion material can help ensure your valve lasts for years.

When shopping for a water pressure-reducing valve, remember that the best ones have a range of features that make them stand out. Check out this top rated water pressure reducing valve list according to your needs. Here’s where you’ll find the right PRV to suit your home.

What are the Benefits of Pressure-Reducing Valves in Residential Areas?

Pressure-reducing valves are installed near the main water supply line, which can help reduce the risk of high water pressure damaging pipes and fixtures. While most homes have some pressure-reducing valves, they are especially beneficial in areas with high water pressure.

By keeping the water pressure at a consistent level, these self-acting automatic control valves can help prolong your plumbing system’s life and prevent costly repairs. Also, these valves can improve your home’s water conservation efforts by helping to prevent leaks and wasted water.

Are There Any Limitations to Pressure Reducing Valves?

Even pressure-reducing valves (PRVs) regulate the pressure in a system by automatically opening and closing as needed to maintain constant pressure, there are some limitations to PRVs:

● PRVs are not designed to operate at extremely high or low pressures. Whenever a system’s pressure exceeds the PRV’s operating range, it will not be able to regulate the pressure properly and may fail.

● Pressure reduction valves can only reduce pressure in a system, not increase it. This means that if the incoming water pressure is too low, the PRV will not be able to raise it to the desired level.

● Debris can accumulate on PRVs over an extended period, reducing their effectiveness or even resulting in failure. Even though most PRVs have some filter to prevent this, you should still think about it.

Pressure Reducing Valve or Pressure Regulator: Which One is Best for You?

Pressure regulator and pressure-reducing valve functions may seem similar, but pressure regulators are considered more accurate than pressure-reducing valves in maintaining the set pressure. This is because pressure regulators adjust the opening of the valve based on a feedback mechanism.

Meanwhile, pressure-reducing valves rely on a fixed orifice to control outlet pressure. Because of this, they are more likely to encounter fluctuation in outlet pressure around its set point.

In terms of controlling the flow rate, pressure-reducing valves have an advantage over pressure regulators. This is because lowering the outlet pressure also decreases the fluid velocity, reducing the flow rate. Conversely, pressure regulators maintain a constant outlet velocity, limiting flow rate control.

Your application should be considered when choosing between a pressure regulator and a pressure-reducing valve. If accuracy and stability are your primary concerns, then a pressure regulator may be the best option. Using a pressure-reducing valve may be more suitable if you require control over the fluid flow rate.