Last Updated on July 30, 2025

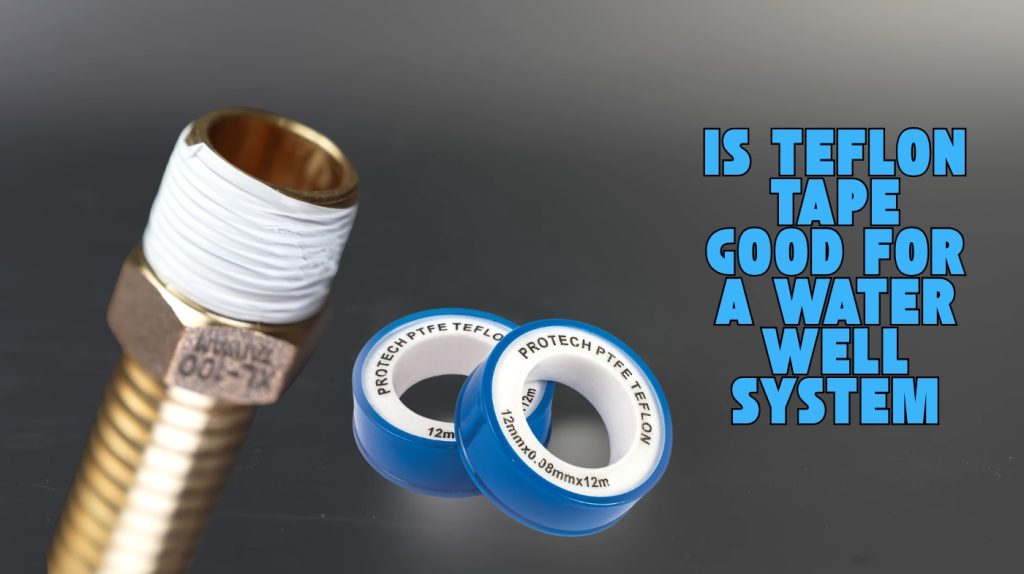

You can use Teflon tape for sealing threaded connections in a water well system, provided you apply 2-3 layers correctly in the thread direction to create a chemical-resistant, corrosion-inhibiting seal.

It’s safe for potable water if NSF-certified, but less durable under high pressure or thermal cycling common in wells. Overuse or poor application can cause leaks or damage.

If you want to guarantee long-term system integrity, understanding its limitations and alternatives is essential.

Key Takeaways

- Teflon tape is chemically inert and safe for potable water when NSF/ANSI 61 certified, making it generally suitable for residential water well systems.

- It provides an effective thread seal and corrosion barrier under standard residential pressures but may degrade over time in fluctuating well conditions.

- Proper application with 2-4 clockwise wraps ensures leak prevention; over-taping or improper installation risks leaks and mechanical failure.

- For high-pressure, industrial, or chemically aggressive well environments, more robust sealants like pipe dope are recommended over Teflon tape.

- Regular inspection and replacement every 2-3 years maintain seal integrity and prevent contamination in water well system connections.

Chemical Composition and Safety Considerations of Teflon Tape

Although you mightn’t see it at a glance, Teflon tape is made from pure polytetrafluoroethylene (PTFE), a synthetic fluoropolymer with a carbon-fluorine backbone that gives it exceptional chemical stability.

This structure, composed of repeating tetrafluoroethylene units (C₂F₄)ₙ, results in approximately 76% fluorine by weight, making PTFE inert and highly resistant to chemicals, solvents, and acids.

PTFE tape also acts as a lubricant and filler that helps create a leak-proof seal between threaded pipe fittings. When you use PTFE tape in water well applications, you benefit from a material that doesn’t react with water, chlorine, or typical contaminants.

Most PTFE tapes are NSF/ANSI 61 certified, ensuring safety for potable water systems. Its chemical resistance is comparable to the chlorine-resistant materials used in top chlorine injection systems, providing reliable performance in disinfection setups.

However, be mindful that some tapes include additives or fillers, which may affect safety and performance. Always verify certification and select pure PTFE tape for reliable, contaminant-free sealing in your well system.

How Teflon Tape Works in Water Well Systems?

When you install threaded connections in water well systems, Teflon tape plays a crucial role by reducing friction and ensuring a tight, reliable seal. It primarily acts as a lubricant, preventing thread seizing and enabling proper torque application.

The tape conforms to minor surface irregularities, enhancing the mechanical seal and minimizing leaks. Compatible with PVC, steel, brass, and other fittings, it withstands moisture and forms a corrosion barrier.

Additionally, proper sealing is essential to prevent contaminants like bacteria and surface water from entering the well, maintaining water safety and potability through effective contaminant prevention.

However, its effectiveness diminishes under high pressure, where other sealants might be needed. Understanding the differences between submersible pumps and external pumps can help in selecting compatible sealants and installation practices.

| Function | Benefit |

|---|---|

| Lubrication | Easier tightening, prevents damage |

| Leak Prevention | Blocks water escape |

| Material Compatibility | Works with common pipe materials |

| Corrosion Barrier | Protects metal threads |

| Pressure Limitations | Suited for residential pressures |

Proper Application Techniques for Effective Sealing

Before applying Teflon tape, clean and dry the threads thoroughly to verify a proper seal. This preparation step aligns with safety measures such as wearing safety goggles and gloves to protect against harmful substances.

Thread Preparation Steps

To guarantee a reliable seal on water well system threads, you must thoroughly clean and prepare the threads before applying Teflon tape. Start by removing all dirt, grease, old tape, or debris using a wire brush or rag.

Inspect threads carefully for damage or corrosion that could compromise the seal. After cleaning, confirm the threads are completely dry to promote proper tape adhesion. Ensure threads are undamaged before wrapping the tape to prevent leaks and ensure a tight seal.

Properly prepared threads prevent leaks and enhance tape effectiveness. This preparation step is vital before wrapping tape, as any residue or moisture can interfere with sealing integrity.

Taking these precise steps ensures the Teflon tape embeds correctly into thread grooves, securing a durable, leak-free connection essential for water well systems.

Additionally, using heavy-duty extension cords with proper insulation is critical when setting up equipment around water well systems to maintain safety and performance.

Wrapping Direction Importance

After preparing the threads thoroughly, you need to focus on how you apply the Teflon tape, starting with the wrapping direction. Always wrap the tape clockwise, matching the thread tightening motion

This prevents bunching or lifting, ensuring a tight, leak-free seal. Wrapping counterclockwise causes tape displacement and weakens thread engagement, risking leaks and mechanical failure.

It is also important to cover at least half the width of the tape during each wrap to ensure a proper seal. Proper maintenance, including winterization procedures, helps protect the entire water system from damage during cold weather.

| Aspect | Importance |

|---|---|

| Wrapping Direction | Must be clockwise |

| Seal Integrity | Prevents leaks by compressing tape |

| Mechanical Fit | Ensures smooth threading, no binding |

| Pressure Resistance | Enhances tape’s ability to resist pressure |

| Tape Adhesion | Prevents tape unraveling during tightening |

Correct wrapping embeds tape into threads, maintains tension, and supports reliable water well connections.

Layering Thickness Guidelines

Although applying Teflon tape may seem straightforward, controlling the layering thickness is critical for an effective seal in water well connections. You’ll want to apply between 2 to 5 wraps, depending on the tape’s thickness and density.

Thicker tapes (around 4-mil) require fewer wraps, usually 2-3, while thinner tapes need more layers for a reliable seal. Wrap the tape tightly around the threads to avoid gaps, but don’t overdo it; excessive layers can damage threads and compromise sealing.

The tape typically comes on a spool with a protective cap for ease of use. Keep these points in mind:

- Choose tape density carefully; higher density (e.g., 1.5 g/cc) offers better durability for demanding applications.

- Ensure each wrap lies flat and snug without overlapping unevenly.

- Avoid over-taping to maintain thread integrity and prevent leaks later. Regular testing frequency helps ensure connections remain secure and leak-free over time.

Limitations and Risks When Using Teflon Tape

You should be aware that Teflon tape’s adhesion can weaken over time, increasing the risk of leaks in water well fittings. This risk can be compounded if the system lacks proper grounding procedures to prevent electrical damage.

Adhesion and Durability Issues

Why does Teflon tape sometimes fail to maintain a reliable seal in water well systems? Although it initially forms a tight barrier, Teflon tape remains a pliable film that doesn’t harden or cure, making it vulnerable to mechanical wear, vibration, and thermal cycling.

This is especially critical in water well systems where sealing reliability is essential for preventing leaks and contamination. Over time, the tape’s grip weakens, and residual layers can reduce thread engagement, causing leaks.

Additionally, it compresses under pressure, risking deformation and seal gaps in high-pressure environments. Consider these factors:

- Tape’s non-solid nature limits long-term durability compared to curing sealants.

- Chemical exposure can degrade tape, impacting sealing performance.

- Repeated application leaves residue that compromises thread connection integrity.

- Since the tape is applied to pipe fittings and not inside the water flow, proper installation is crucial to prevent potential contamination.

Installation and Pressure Challenges

When installing Teflon tape on water well systems, precise application is crucial to guarantee a reliable seal and avoid leaks. Wrap the tape tightly in the direction of the threads, using the correct width and number of layers.

Because the tape is non-adhesive and malleable, it conforms to pipe threads to fill small gaps and ensure a watertight seal. Consider the check valve installation to maintain system integrity when applying Teflon tape.

Overapplication or multiple layers without cleaning can misalign fittings or crack threads, compromising seal integrity. Teflon tape’s pressure limitations mean it’s suitable mainly for residential or small commercial wells with moderate pressure.

In high-pressure systems, compression can deform the tape, creating gaps and risking hazardous leaks or failures. For these environments, use anaerobic or specialized thread sealants that offer stronger bonding and better pressure resistance.

Corrosion Resistance and Environmental Durability

How does Teflon tape guarantee lasting protection against corrosion in water well systems? It forms a hydrophobic, chemically inert barrier that prevents moisture and corrosive agents from contacting metal threads, preserving their integrity.

This sealant method is particularly effective for preventing leaks at threaded joints in copper piping systems, a common component of water wells. Its resistance to water absorption and common plumbing chemicals ensures durable sealing, even in fluctuating temperatures and moist environments.

Additionally, the tape’s temperature-resistant properties allow it to perform reliably in both hot and cold conditions common in well systems. Key aspects include:

- Chemical Inertness: Doesn’t react with typical well substances, avoiding degradation.

- Environmental Stability: Maintains malleability and seal integrity despite temperature changes and subsurface moisture.

- Physical Barrier Function: Prevents exposure of metal threads to corrosive elements, extending component lifespan.

While effective for residential and small commercial wells, understand that Teflon tape’s physical sealing limits its use in high-pressure environments or aggressive chemical environments.

Maintenance Tips for Long-Term Performance

Although Teflon tape provides reliable sealing for water well threads, maintaining its effectiveness requires proper application and regular inspection. Wrap the tape clockwise with 2 to 4 tight layers after thoroughly cleaning and drying threads.

Inspect periodically for leaks or tape degradation, replacing tape during maintenance or if seepage appears. Avoid over-tightening, which stresses threads and compromises sealing. Use Teflon tape on damaged or worn threads, as this can lead to leaks and reduce sealing effectiveness (damaged or worn threads).

| Task | Frequency | Emotional Impact |

|---|---|---|

| Inspect connections | Every 6 months | Confidence |

| Clean threads | Before wrapping | Assurance |

| Replace tape | Every 2-3 years | Peace of mind |

| Avoid overtightening | Every installation | Safety |

Selecting the Right Teflon Tape for Potable Water

Since potable water systems demand strict safety and reliability, selecting the right Teflon tape involves understanding regulatory approvals, tape density, and chemical resistance.

You should choose PTFE tape that meets NSF standards and FDA Regulation 21-CFR 177.1550 to guarantee safety for drinking water. Choosing Teflon tape for potable water requires NSF and FDA compliance to ensure safety and reliability.

Tape density affects suitability: low-density tapes (0.2–0.4 g/cm³) provide flexibility and effective sealing for typical water plumbing, while higher density tapes handle elevated temperatures and harsher chemical environments.

For example, PTFE Teflon® Thread Seal Tape with a 0.4 density is commonly used for sealing threads on plumbing fittings. PTFE’s chemical inertness guarantees no leaching or degradation in potable water.

Key factors to consider include:

- Regulatory compliance (NSF, FDA, USDA approvals) for potable water use

- Tape density and temperature rating tailored to your specific water system

- Chemical purity and resistance to prevent contamination and ensure longevity

Comparing Teflon Tape With Alternative Sealants

When choosing a sealant for water well systems, you’ll find that Teflon tape offers ease of use and effective sealing for many applications, but alternative sealants provide advantages in durability and pressure resistance.

Teflon tape is compatible with various pipe materials and resists corrosion, yet it can degrade over time, especially under fluctuating pressure. PTFE tape, being chemically inert, ensures resistance to most solvents and acids which is beneficial in diverse water well environments.

In contrast, pipe dope and specialized thread sealants cure to form solid bonds, enhancing longevity and leak prevention. These alternatives also handle high-pressure environments better and offer improved chemical resistance, though they may require more careful application and preparation.

If your system operates under standard residential pressures, Teflon tape usually suffices; however, for industrial or high-pressure wells, opting for a robust sealant guarantees greater reliability and reduces maintenance needs.

When to Seek Professional Advice for Well System Sealing?

Selecting the right sealant for your water well is only part of the process; knowing when to call in professional expertise can safeguard the integrity and safety of your well system. Complex geology, regulatory compliance, and specialized sealing techniques often exceed DIY capabilities.

Professionals ensure proper annular seal placement, prevent cross-contamination, and meet local codes. You should consult an expert when dealing with:

- Wells in fractured bedrock or multiple aquifers requiring precise seal design

- Regulatory requirements mandating licensed installers and certified materials

- Difficult sealing methods like tremie grout placement or deep well applications

In particular, professionals will ensure the seal extends to the first impermeable layer, which is crucial to prevent contamination pathways.

Engaging specialists helps avoid contamination risks, guarantees durability, and ensures legal compliance, making it a critical step beyond just selecting materials like Teflon tape.

Frequently Asked Questions

Can Teflon Tape Be Used on Plastic Well Pump Fittings?

You can use Teflon tape on plastic well pump fittings safely and effectively if you follow best practices. Wrap the tape clockwise in thin, tight layers to avoid thread damage or fitting cracks.

Clean threads before applying tape, and tighten fittings carefully to prevent overtightening. While Teflon tape seals well under low to moderate pressure, inspect and replace it regularly to maintain a leak-free connection and guarantee long-term reliability.

Does Teflon Tape Affect Water Taste or Odor?

You’d expect a harmless strip of Teflon tape to flood your water with weird tastes or odors, right? Actually, PTFE tape is chemically inert and stable under normal water temperatures, so it doesn’t impart flavors or smells.

If you notice anything odd, it’s usually from fresh tape residue, which flushes out quickly. Focus on other plumbing materials or disinfectants—those are the real culprits behind taste or odor issues in your water system.

How Does Temperature Variation Impact Teflon Tape Seals?

Temperature variation causes Teflon tape to expand and contract, which can loosen seals over time. When it gets cold, the tape becomes brittle, risking cracks and leaks. High temperatures up to about 120°F maintain good sealing, but beyond that, the tape weakens and degrades faster.

To maintain seal integrity, you need proper installation with the right tape thickness and regular inspections, especially in systems experiencing frequent temperature cycling.

Is Teflon Tape Biodegradable or Environmentally Friendly?

You might say Teflon tape is a tough customer when it comes to breaking down it’s not biodegradable due to its stable PTFE makeup. While it’s great for sealing, it lingers in the environment much longer than you’d hope, contributing to plastic waste.

Its chemical resilience means it resists degradation, but that also means it’s less eco-friendly. If you want greener options, look for newer tapes made from recycled or bio-based materials.

Can Teflon Tape Be Reused After Removing a Pipe Joint?

You shouldn’t reuse Teflon tape after removing a pipe joint. Once applied, the tape loses adhesion and can leave residue, compromising the seal’s integrity. Reapplying old tape increases the risk of leaks and thread damage.

For a reliable seal, always remove the old tape completely and apply a fresh layer during reassembly. This practice guarantees proper sealing and helps maintain system safety and performance.

Looking Beyond Teflon: Better Sealing Alternatives for Wells

Think of Teflon tape as the tight seal on a well-crafted puzzle piece in your water well system. When applied correctly, it creates a reliable barrier against leaks and corrosion, ensuring smooth operation.

However, it’s not a one-size-fits-all solution—knowing its limits and selecting the right type for potable water is key. Use it wisely, maintain your system, and don’t hesitate to call a pro if the fit feels off.