Last Updated on August 9, 2025

Yes, your water heater can cause low water pressure, especially if hard-water minerals build up inside, forming limescale that narrows flow paths. Sediment accumulating at the tank bottom also blocks water flow, reducing hot water pressure.

Partially closed or faulty valves and undersized pipes connected to the heater contribute to pressure drops as well. Proper maintenance like flushing and valve checks can restore flow. Understanding these factors helps you pinpoint and fix pressure issues efficiently.

Key Takeaways

- Mineral and sediment buildup inside water heaters restricts flow, reducing hot water pressure and delivery speed.

- Faulty valves or clogged internal components in the heater can cause pressure drops and inconsistent water flow.

- Sediment accumulation leads to blockages, decreasing water heater efficiency and lowering outlet pressure.

- Mechanical issues like damaged dip tubes or corroded tanks within the heater reduce water flow and pressure.

- Regular maintenance, such as flushing and valve inspection, is essential to prevent water heater-related low pressure.

How Hard-Water Minerals Affect Water Pressure in Heaters?

Because hard water carries high levels of dissolved calcium and magnesium, these minerals tend to accumulate inside your water heater, forming limescale deposits that restrict water flow.

This buildup narrows the internal flow paths, increasing resistance inside heating elements and pipes connected to your heater. Mineral deposits form inside tanks, coating heating elements and reducing efficiency, which further contributes to pressure drops and heating delays.

As a result, water pressure downstream drops, causing slower hot water delivery at your fixtures. Over time, mineral scaling worsens, exacerbating flow restrictions and potentially causing localized weak spots that may leak.

Regular maintenance, such as draining the water from the heater, is essential to prevent buildup and maintain water pressure. These changes disrupt the consistent pressure you expect, impacting your water system’s performance.

To maintain proper water pressure and avoid costly repairs, you’ll need regular maintenance like flushing or descaling, especially if you live in a hard water area prone to mineral buildup inside your water heater.

Impact of Sediment Buildup on Hot Water Flow

When sediment builds up inside your water heater, it directly restricts hot water flow by forming blockages and narrowing passageways. This sediment accumulation coats the tank’s bottom, reduces its capacity, and increases internal flow resistance, causing inconsistent water delivery.

Over time, sediment layers increase the workload on the heater, further worsening flow issues. You’ll notice rumbling noises and fluctuating water temperatures signaling sediment interference.

To understand the impact, consider these key effects:

- Sediment forms physical barriers, reducing hot water flow rate.

- Blockages downstream worsen low water pressure at fixtures.

- Sediment buildup decreases heating efficiency, affecting temperature consistency.

- Mechanical strain on components leads to leaks and flow disruptions.

Regular tank flushing and sediment removal are essential to restore proper flow and maintain water heater performance. Ensure proper disposal of the drained water to prevent environmental contamination.

Role of Flexible Supply Lines in Water Pressure Issues

Although flexible supply lines offer convenience and ease of installation, their material properties and condition can substantially affect your water pressure. These lines typically combine a polymer inner hose with a braided stainless steel shell.

Over time, the polymer can bulge or rupture under pressure, reducing flow.

Corrosion of the stainless steel braid, especially from chlorides, weakens the hose, potentially causing leaks and pressure drops. The diameter of the line also matters; smaller sizes restrict volume despite higher velocity, leading to lower pressure at fixtures.

The outer shell made of braided stainless steel provides essential support to handle water pressure variations. Unlike submersible pumps, inline pumps, which flexible supply lines often connect to, are more susceptible to overheating due to their external placement.

Improper installation—like over-tightening plastic coupling nuts or creating sharp bends—can cause microcracks or internal obstruction. Regular inspection for discoloration, damage, and correct sizing ensures your flexible supply lines maintain ideal water pressure and avoid unexpected failures.

Effects of Partially Closed or Malfunctioning Shut-Off Valves

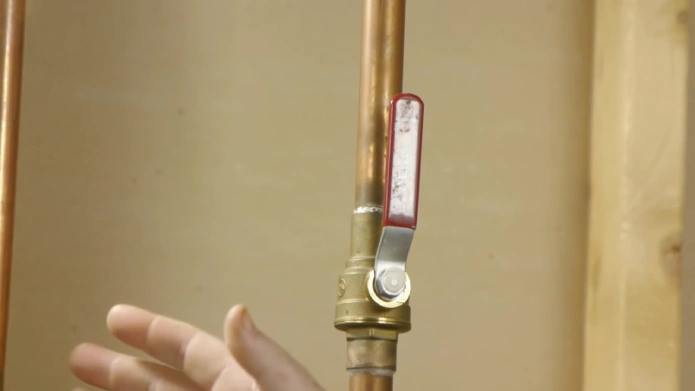

You should always guarantee the shut-off valve is fully open, as even partial closure can reduce hot water pressure considerably. Watch for symptoms like fluctuating pressure or inconsistent flow, which often indicate valve malfunction or sediment buildup.

Proper maintenance and precise temperature control can help mitigate these issues. Regularly inspect and maintain valves to prevent these issues and restore proper water heater performance.

A malfunctioning valve can cause pressure irregularities that may stress the water heater system and lead to leaks or damage.

Valve Position Impact

Because a shut-off valve controls water flow directly, any partial closure or malfunction can considerably reduce hot water pressure throughout your system. When a valve isn’t fully open, it restricts water passage, limiting flow rate and lowering pressure at fixtures.

This restriction upstream of the heater can reduce the effective pressure on the hot water side, impacting delivery. Using an appropriate wire gauge in extension cords or plumbing systems can help maintain efficient performance and avoid pressure loss.

You might also experience inconsistent pressure and fluctuating flow rates due to valve positioning. Additionally, if the pressure remains excessively high, such as around 140 psi, it may indicate a pressure regulation issue rather than just valve restriction.

Here’s what to keep in mind:

- Partially closed valves reduce flow volume and pressure.

- Flow restriction affects water heater performance.

- Valve position impacts pressure independently of the heater.

- Repeated mispositioning degrades system efficiency over time.

Valve Malfunction Symptoms

When shut-off valves malfunction or remain partially closed, several symptoms can alert you to underlying issues affecting your water heater system.

You might notice visible leaks or puddles near the valve, signaling failure to seal properly, which can cause corrosion or water damage over time. These issues often result from a damaged shut-off valve body that no longer seals effectively.

Listen for unusual noises like hissing, gurgling, or banging, indicating pressure irregularities or valve sticking. These unusual noises often serve as an early warning of valve problems that require attention.

Temperature fluctuations or sudden drops in hot water can result from valve issues affecting pressure relief. You may also find the valve stiff or hard to operate, complicating manual tests and indicating mechanical failure or mineral buildup.

Ignoring these signs risks pressure buildup, potential tank damage, and safety hazards. Prompt professional evaluation is essential to prevent costly repairs and maintain safe water heater operation.

Valve Maintenance Tips

Although shut-off valves may seem simple, maintaining them properly is essential to avoid low water pressure issues caused by partial closures or malfunctions. Partially closed or malfunctioning valves restrict water flow, leading to inconsistent hot water delivery and pressure drops.

To keep your valves functioning ideally, follow these tips:

- Inspect valves regularly for corrosion, mineral buildup, and leaks to detect early signs of malfunction.

- Exercise valves periodically by fully opening and closing them to prevent seizing or sticking.

- Clean inside valve bodies to remove sediment that can block water flow and reduce pressure.

- Replace worn or damaged valves promptly to restore proper flow control and maintain stable water pressure.

Additionally, ensuring that the temperature and pressure relief valve is properly installed with a connected discharge pipe that safely directs water away can prevent dangerous pressure buildup in your water heater system, indirectly supporting consistent water pressure.

This valve is equipped with two sensing points to activate and release excess pressure safely. Regular valve maintenance also prevents pump failure caused by overworked components in water systems.

Influence of Pipe Size and Water Distribution on Pressure

You need to ensure the pipe diameter is carefully because it directly affects water pressure and flow in your system. An undersized pipe increases friction and pressure loss.

Since pressure varies with the radius to the 4th power, even small changes in diameter can cause significant pressure differences, demonstrating the critical impact of pipe diameter on pressure. Oversized pipes can lower velocity and reduce pressure at fixtures.

Designing an efficient water distribution layout ensures balanced pressure throughout your home, especially when multiple fixtures operate simultaneously. Select the appropriate water pressure regulator size based on your pipe size and flow requirements to maintain optimal system performance.

Pipe Diameter Impact

Since pipe diameter directly influences water velocity and frictional losses, it plays a crucial role in determining pressure within your plumbing system. Smaller pipes increase water velocity to maintain flow, which raises frictional resistance and lowers static pressure according to Bernoulli’s principle.

This means narrower pipes cause noticeable pressure drops, especially near your water heater. Proper installation also requires planning for maintenance access, similar to how one would consider sump pump location in basement finishing.

Consider these key points:

- Pressure drops exponentially as pipe diameter decreases due to higher hydraulic resistance.

- Flow rate depends on the fourth power of pipe radius, making diameter critical for maintaining adequate pressure.

- Smaller diameters increase turbulence, further exacerbating pressure loss.

- Installing undersized pipes around your water heater can restrict flow and reduce outlet pressure.

Because the pressure drop increases with flow rate and pipe resistance, managing pipe size is essential to minimize losses and maintain stable pressure. Proper pipe sizing ensures efficient pressure and flow, preventing low water pressure issues linked to your water heater.

Distribution System Design

Proper pipe sizing around your water heater sets the foundation, but maintaining consistent water pressure throughout your entire system depends heavily on the overall distribution design. Pressure zones, defined by upper and lower limits, help balance elevation changes and friction losses, ensuring uniform supply.

However, recognize that pressure criteria differ across regions, which influences design and operational practices. Gravity-fed sections provide stable pressure without added energy, while pumped zones adjust pressure to meet demand but require control to avoid surges.

Using external pumps in pumped zones can affect pressure regulation and energy consumption. You’ll notice pressure drops downstream due to head losses; strategic placement of storage tanks and pressure-reducing valves mitigates these issues.

Monitoring demand patterns lets you adapt pressure settings, preventing low-pressure complaints or pipe damage. Ultimately, a well-designed distribution system integrates pipe sizing, zoning, and control devices to maintain steady pressure, optimize energy use, and protect your plumbing infrastructure.

Consequences of Sediment Accumulation Inside Water Heater Tanks

When sediment accumulates inside your water heater tank, it creates an insulating barrier that traps heat and forces the system to work harder to reach the desired temperature. This buildup can cause several issues that affect your water heater’s performance and longevity.

Here are the main consequences:

- Reduced heating efficiency—sediment traps heat, increasing energy use and utility costs.

- Limited hot water supply—sediment decreases tank volume, causing shorter hot water availability.

- Structural damage—uneven heating stresses the tank, leading to corrosion, leaks, and possible failure. Sediment also provides an environment for bacterial growth that accelerates internal corrosion.

- Water quality issues—sediment causes cloudy, rusty water and may produce unpleasant odors.

Plumbing Design Factors That Reduce Hot Water Pressure

Although many factors influence hot water pressure, the design of your plumbing system plays a vital role in maintaining consistent flow.

Undersized pipes and long runs create friction losses that reduce pressure, especially when multiple fixtures operate simultaneously. You should guarantee proper pipe sizing and minimize unnecessary bends or fittings to limit resistance.

Installing Pressure Reducing Valves (PRVs) improperly or setting them too low can cause significant pressure drops; regular adjustment and maintenance are essential. PRVs work by using a spring-loaded mechanism to modulate water flow and maintain safe pressure levels.

Positioning pressure regulators carefully is also essential to stabilize fluctuating municipal supply without compromising hot water delivery. Finally, consider fixture demand and select low-pressure or high-efficiency models to prevent excessive pressure loss.

Mechanical Problems Within Water Heaters Leading to Pressure Drops

If you notice a sudden drop in hot water pressure, mechanical problems inside your water heater could be the cause. Sediment buildup, clogged filters, and worn parts often restrict flow and lower pressure.

Sudden hot water pressure drops often stem from mechanical issues like sediment buildup and worn parts. Here are four common mechanical issues to check:

- Sediment and Scale Buildup: Mineral deposits reduce tank capacity and clog pipes, limiting water flow.

- Clogged Filters and Aerators: Debris blocks internal filters or faucet aerators, decreasing pressure.

- Faulty Pressure Components: Malfunctioning regulators or relief valves disrupt stable water pressure.

- Aging Mechanical Parts: Corroded tanks, worn valves, or damaged dip tubes cause leaks and flow restrictions.

Regular maintenance—flushing tanks, cleaning filters, and inspecting parts—helps you avoid these pressure drops and maintain efficient hot water delivery. Maintaining water pressure within the optimal range of 40 to 60 psi is essential to prevent strain and damage to the water heater system.

External Water Supply Conditions Affecting Water Pressure

Since your home’s water pressure depends heavily on the external supply system, issues beyond your property line can directly affect flow and stability.

Main water line leaks, aging pipes, or damage from roadwork often reduce pressure before water even reaches your plumbing. A broken pressure regulator can fail to control incoming water pressure, causing dangerous pressure levels that stress the plumbing system.

Seasonal factors like freezing temperatures or drought limit water availability and disrupt pressure balance. Municipal fluctuations—such as maintenance shutdowns, demand spikes, or pressure regulator malfunctions—cause intermittent drops.

Additionally, topography plays a role: if your home sits at a higher elevation or far from the water source, pressure naturally decreases due to friction and gravity. External obstructions like tree roots or sediment buildup further restrict flow.

Maintenance Practices to Restore and Improve Water Pressure

When you maintain your water heater and plumbing components regularly, you can restore and improve water pressure effectively.

- Start by flushing the tank annually to remove sediment that blocks water flow. This practice removes sediment, improving heating efficiency and reducing energy costs.

- Next, inspect valves—especially the temperature and pressure relief valve—and replace any that are faulty to guarantee ideal flow and safety.

- Third, check and adjust the pressure regulator to maintain stable pressure within 40-60 psi, improving overall system performance.

- Finally, inspect pipes and fixtures for mineral buildup that narrows flow paths; clean or replace affected parts and consider water softening systems in hard water areas.

Following these steps will help you maintain consistent water pressure and prolong your water heater’s lifespan.

Frequently Asked Questions

Can a Water Heater Cause Low Cold Water Pressure?

Yes, a water heater can cause low cold water pressure if problems affect shared pipes or valves upstream. For example, sediment buildup, partially closed shut-off valves, or kinks in pipes near the heater can restrict flow, lowering pressure.

Also, leaks or faults around the heater might reduce cold water pressure depending on your plumbing layout. So, if you notice low cold pressure alongside hot water issues, inspect your water heater components and connections carefully.

Does Water Heater Age Affect Water Temperature but Not Pressure?

You’ll find that your water heater’s age mainly impacts water temperature, not pressure. Over time, sediment buildup and worn heating elements reduce heating efficiency, causing inconsistent temperatures.

However, water pressure depends on external factors like municipal supply and plumbing valves, not the heater’s age. That said, aging components inside the heater may indirectly affect flow if valves get blocked, but overall, age affects temperature more than pressure.

How Do Water Heater Thermostat Settings Impact Water Pressure?

Your water heater’s thermostat settings directly affect water pressure by controlling temperature and internal pressure. Higher settings cause water to expand, increasing pressure inside the tank, which can trigger relief valves and reduce flow.

Overheating stresses components, potentially causing leaks or pressure drops. Keeping the thermostat at or below 120°F helps maintain stable pressure, prevents valve activation, and ensures consistent hot water flow without damaging your system or waste.

Can Water Heater Anode Rods Influence Water Pressure Issues?

You mightn’t realize it, but your water heater’s anode rod can indirectly affect water pressure. As it corrodes, rust and sediment increase inside the tank, which can clog outlets and reduce flow.

While the rod itself doesn’t lower pressure directly, neglecting its replacement speeds corrosion that impairs water flow.

Is Low Water Pressure Related to Water Heater Energy Source Type?

You won’t find low water pressure directly linked to your water heater’s energy source. Whether your heater runs on gas, electric, or solar, water pressure mainly depends on your municipal supply or well pump.

While gas heaters heat water faster and electric ones may struggle with flow under high demand, these affect hot water availability, not the actual pressure in your pipes. Focus on plumbing infrastructure for pressure issues.

Avoid the Drip: Preventing Pressure Problems Early

Think of your water heater as the heart of your hot water system—when it struggles with sediment, mineral buildup, or mechanical issues, the flow weakens like a faltering pulse.

By regularly maintaining valves, supply lines, and internal components, you keep this heart robust and your water pressure steady. Address these factors promptly to ensure your system runs efficiently, delivering the consistent hot water flow you rely on every day.