Last Updated on July 16, 2023

A sump pump can mean the difference between a dry basement or costly water damage, but what happens when yours fails?

When sump pumps stop working, it could be due to several possible culprits. From sudden power outages and faulty switches or motors all the way through clogs that overpower your system’s capacity. Even incorrect installation can doom the effectiveness of a pump.

Be sure to keep an eye on things and take action before you’re dealing with more than just a wet carpet.

Don’t let a sump pump failure take you by surprise. Discover what could be behind sudden stoppage and how to ensure your system keeps working when it matters most.

Why Do Sump Pumps Fail: Uncovering the Causes

A sump pump failure can be a real hassle, but luckily there are ways to catch possible problems before disaster strikes. Let’s delve into some of the most typical causes and how you can solve the sump pump problem and keep your pump running smoothly.

1. Absence of Backup Generator or Battery

Power failure is one of the most common reasons why sump pumps fail. If the power goes out, the sump pump will stop working, and water will start to accumulate in the basement or crawlspace.

To prevent power failure from causing a sump pump failure, you can invest in a battery backup sump pump or power source, such as a battery backup or generator.

For an affordable and good quality generator, you can rely on our comprehensive review for an affordable generator for sump pump. We have carefully selected and evaluated top-rated generators that perfectly suit the requirements of a sump pump system.

Our thorough analysis includes detailed specifications and features of each generator. This ensures that you can easily find a high-quality yet budget-friendly generator for your sump pump.

2. Motor Malfunction

A motor malfunction is another reason sump pumps fail. The motor is the main part that drives the pump impeller and moves water out of the pit.

Over time, the motor can wear down, become damaged or burn out entirely, leading to a sump pump failure.

Routine maintenance can prevent motor malfunction by inspecting and cleaning the motor, ensuring its proper functioning, and replacing any worn-out or faulty parts.

3. Switch Failure

The switch is another vital component of a sump pump that can malfunction and cause sump pump failure. The switch signals the sump pump to turn on/off when a certain water level is reached.

A faulty switch will prevent the sump pump from turning on, which could lead to water accumulating in the pit.

Switch failure can occur due to an accumulation of debris or sediment in the pit or a broken or stuck float switch. Regular maintenance and cleaning of the sump pit and switch can prevent this kind of failure.

4. Installation Problems

Installation problems can cause sump pumps to fail. Incorrect installation can cause mechanical stress, damage the motor, and cause the switch to malfunction.

Also, improperly sized or installed sump pumps can’t keep up with the volume of water and overflow, leading to basement flooding.

It’s essential to ensure proper sump pump installation and regularly inspect and maintain it for optimal performance.

5. Clogged Intake

Another common cause of sump pump failure is a clogged intake. Over time, debris, such as dirt, sand, and rocks, can accumulate around and inside the pump intake, making it difficult for the pump to pull in water.

When this occurs, the pump may run continuously, causing the motor to overheat and eventually fail. To prevent this from happening, it is important to regularly clean the sump pump intake to remove any accumulated debris.

This can be done by manually removing any visible debris or by using a specialized cleaning solution specifically designed for sump pumps.

6. Overloading

Sump pumps are designed to handle a specific amount of water flow, and anything exceeding that amount can cause an overload that may lead to pump failure. Overloading can occur for a variety of reasons, such as heavy rainfall or improper drainage.

When the pump is overloaded, it may struggle to keep up with the amount of water it is being asked to move, which may cause the motor to burn out or the pump to fail altogether.

Regularly checking the pump’s capacity and ensuring that it is appropriately sized for its intended use can help prevent overloading.

7. Frozen or Clogged Discharge Line

During the wintertime, the discharge line of a sump pump may become frozen or clogged with ice, snow, or debris. This can result in the water being unable to exit the pump, leading to a backup that may cause the pump to fail.

The discharge pipe should be insulated and protected from freezing temperatures in order to prevent this from occurring.

Also, regularly checking the discharge line for any signs of obstruction or debris can help keep the pump functioning properly.

8. Poor Quality

Another reason why sump pumps fail is due to poor quality. Low-cost sump pumps that are constructed from cheap, substandard materials often result in frequent breakdowns or inferior performance.

These types of pumps may not have sufficient power to handle the amount of water or may be prone to clogging issues.

In contrast, high-quality, well-manufactured sump pumps are more reliable and can handle heavier water loads, ensuring peak performance and longevity.

9. Debris Jams

As mentioned earlier, debris jams are one of the leading causes of clogged discharge lines. However, debris can also accumulate in the sump pump pit, leading to pump malfunction.

Don’t let the mud, rocks, and other detritus in your sump pit play havoc with your pump. Debris accumulation can prevent water from draining properly, potentially leading to malfunction.

But don’t despair. If you’re vigilant about cleaning out the stuff that accumulates over time, then you should be able to avoid any major headaches down the line.

10. Incorrect Pump Model

Sump pumps can also fail if they are the incorrect model for the job. You should choose the right sump pump for your needs based on its size and power.

If a pump is too small, it will not be able to handle the volume of water, leading to pump failure. On the other hand, if the sump pump is too powerful for the job, this can lead to reduced efficiency and higher energy costs.

Consider the specs and features before buying a sump pump to make sure it’s the right one.

11. Defective Parts

Although sump pumps may last for several years, it is important to note that they are made up of various mechanical parts that may fail over time. Flawed or worn-out parts, such as a broken impeller or a malfunctioning float switch, can lead to sump pump failure.

In most cases, these issues can be resolved by replacing the problematic part. It is essential to keep a watchful eye on your sump pump for signs of defects. Such as unusual noises or inadequate water discharge, and to address any problems promptly to avoid costly repairs or replacements.

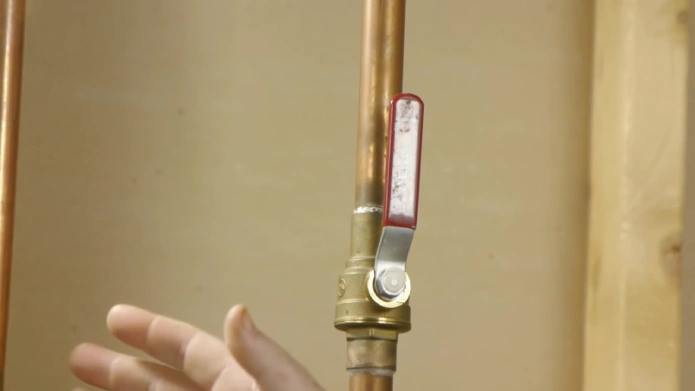

12. Check Valve Failure

Another common reason for sump pump failure is check valve failure. The check valve in a sump pump is designed to prevent water from flowing back into the sump pit after exiting the pump discharge line.

If the check valve malfunctions, it can cause the water to flow back into the sump pit, resulting in the pump’s repetitive cycles, overheating, and ultimately, pump failure.

Regular sump pump maintenance can prevent or catch a check valve failure before it damages the pump and compromises its efficiency.

13. Electrical Issues

Electrical issues can also cause sump pump failure. The sump pump motor uses electricity, and a power outage or surge can harm the pump’s performance.

Also, the electrical motor wires and connections may corrode over time, leading to electrical shorts or a complete halt in pump operation.

14. Worn-Out Bearings

The bearings in a sump pump are crucial components that help the pump impeller rotate smoothly. Bearings that are worn out, corroded or damaged can cause excessive noise, vibration, or a complete shutdown of the pump.

Regular maintenance, such as lubrication and cleaning, can prolong the bearing’s life and maintain the sump pump’s optimal performance for many years.

Failure to carry out these maintenance practices can lead to operational inefficiencies and result in costly repairs or replacements in the long run.

15. Age

Sump pumps may also fail simply due to old age. Over time, the various components of the pump may wear out or become damaged, causing it to function less efficiently or not at all.

You can extend the life of a sump pump with regular maintenance and careful monitoring, but eventually, they’ll need to be replaced.

It is important to keep track of the sump pump’s age and be aware of any signs that it may be reaching the end of its lifespan.

Regularly checking for leaks, strange noises, or other signs of malfunction can help prevent a sudden failure and ensure the pump’s longevity.

Will a sump pump burn out?

It is possible for a sump pump to burn out due to several reasons. This occurs when the voltage from the power supply increases too high, overheating or overworking the system until it shuts off. An undersized pump can also cause this same issue, as well as a faulty float switch and an underpowered model.

Sump pumps that are made with low-quality materials and components are also prone to failure. These cheaper pumps lack the durability needed to withstand continuous use and are unable to handle heavy-duty tasks.

Can a Burnout Sump Pump be Repaired?

It depends on the extent and nature of the damage to the sump pump. In some cases, a burnout sump pump can be repaired, but in other cases, it may be more cost-effective and practical to replace the pump altogether.

If the motor or other critical components of the pump have been severely damaged due to burnout, it may not be possible to repair it.

But, if the damage is minor and limited to certain parts or components, such as the impeller or float switch, replacing those parts and getting the pump working again may be possible.

Do I need to lubricate my sump pump bearings to avoid unexpected failures?

It depends on the type of sump pump you have. Some sump pumps have sealed bearings that do not require lubrication, while others have occasional lubrication.

If your sump pump has sealed bearings, you do not need to lubricate them. Sealed bearings are designed to be maintenance-free, and adding lubrication could actually damage them.

If your sump pump has bearings requiring lubrication, it’s important to follow the manufacturer’s lubrication frequency and type recommendations.

Safeguard Your Home with Correct Functioning Sump Pump

Don’t let the nightmare of a flooded basement be your reality. Maintaining and protecting your home with a sump pump is important, but it can easily go wrong. Keep an eye out for power failures, motor issues, clogs or incorrect installation, which could lead to damaged property.

Arm yourself against these disasters by having backup power ready just in case, plus ensuring you keep up regular inspections and cleaning of the unit itself.

To ensure ultimate peace of mind when it comes to keeping those aggravating floods away from your house, don’t forget about engaging professional help for correct setup too. After all, prevention is better than cure.