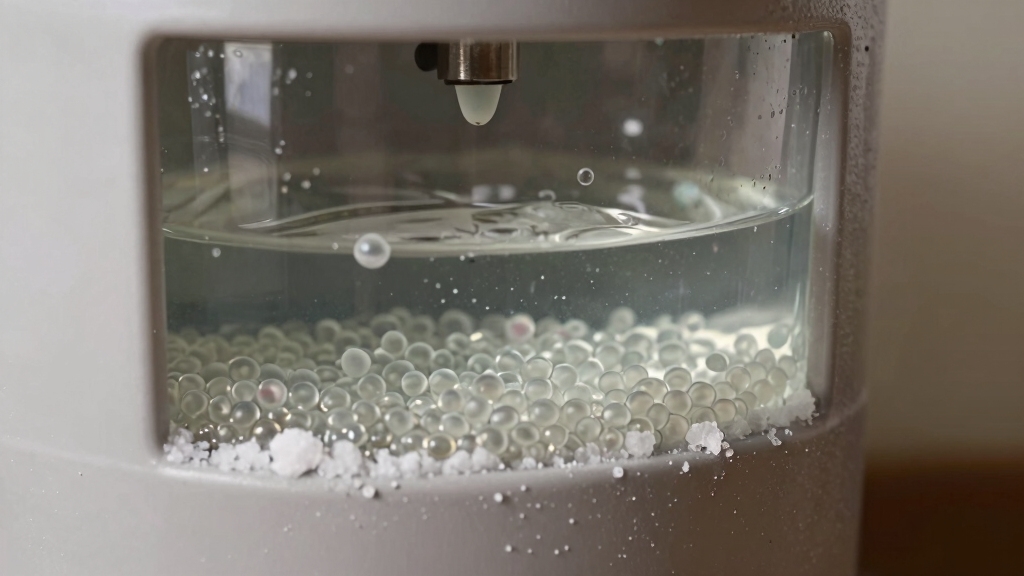

You should keep the water level in your brine tank between about one quarter and six inches below the tank top after regeneration to assure proper salt dissolution and brine strength.

Too much water often indicates salt bridging or float valve issues, while too little limits brine quality. Use a ruler or sensor to check levels consistently, and avoid overfilling to prevent blockages.

Understanding why water levels vary and spotting issues early helps maintain efficient cycles and system longevity.

Key Takeaways

- Maintain water level between one quarter and six inches below the brine tank top for proper brine concentration post-regeneration.

- Typical water depth in residential tanks is 1–3 inches above the brine well after regeneration.

- Avoid overfilling to prevent salt bridging, which blocks water access and affects brine quality.

- Salt dose and pellet type influence residual water volume, with denser pellets reducing visible free water.

- Use measuring tools or sensors to verify water depth consistently matches manufacturer and system specifications.

Understanding Wet-Brine and Dry-Brine Systems

Although both wet-brine and dry-brine systems aim to guarantee meat flavor and moisture retention, they operate through distinct mechanisms: wet brining submerges the meat in a saline solution to allow salt and water absorption, while dry brining applies salt directly, relying on the meat’s own moisture to create a concentrated brine.

Wet brining uses about a 5% salt solution by water weight, typically 50-60 g/L, soaking lean cuts like poultry or fish for 1-2 days to guarantee even seasoning and added moisture. This method is especially useful for lean or dry cuts that need extra moisture and tenderizing.

Dry brining applies roughly 2% salt by meat weight, allowing the meat’s moisture to dissolve the salt and form a brine that reabsorbs, promoting evaporation and crisp skin.

Typical Water Levels Recommended by Manufacturers

Manufacturers typically recommend maintaining a water level of 1 to 3 inches above the top of the brine well or overflow in residential wet-brine tanks after regeneration. This safeguards proper operation of the brine valve and prevents the tank from drying out, which could impair brine draw.

Tanks constructed with maintenance-free fiberglass reinforced plastic provide long-term durability to withstand these water levels without damage. Properly functioning valves also help to maximize efficiency by regulating water flow during regeneration.

Larger capacity tanks often specify 2 to 4 inches in the tank body, controlled by the brine well to avoid overflow. Compact units may require shallower levels to minimize salt sludge formation.

| Tank Type | Recommended Water Level |

|---|---|

| Standard Residential | 1–3 inches above overflow |

| Large Capacity | 2–4 inches in tank body |

| Compact Softener | Under 1–2 inches refill |

| Dry-Salt with Float | ~1–3 inches repeatable column |

Factors Influencing Water Level Variations

You know, the amount of salt you pack into the brine tank really impacts the water level after regeneration. It’s interesting how that works, right? Plus, the settings on the control valve are super important too.

They manage how much brine gets drawn and refilled with each cycle, which can make a big difference. To maintain efficiency, it’s important to keep the salt level at least one-quarter full of the tank at all times. Regular maintenance of the control valve helps prevent mineral buildup and ensures consistent operation.

Oh, and let’s not forget about salt bridging! That can create those annoying pockets of trapped water. It can lead to some pretty misleading water readings, making it seem like there’s less water than there actually is.

Salt Volume Impact

Several factors related to salt volume directly influence the water level you observe in a brine tank after regeneration. Salt displaces water, so a tank filled with densely packed pellets may show little visible water despite adequate brine volume.

Salt condition also matters: bridging or mushing can alter free water availability and affect float operation. The type and size of salt pellets impact packing density, changing water displacement.

Additionally, the salt dose per regeneration affects how much water remains post-cycle. Installing a check valve in the system can help maintain proper water levels by preventing backflow during regeneration.

It is important to maintain only the appropriate amount of water needed in the tank to ensure effective regeneration water level maintenance.

- Salt volume displaces standing water, reducing visible free water.

- Bridging or mushing changes effective brine capacity and water retention.

- Pellet size and salt type influence dissolution rates and packing density.

- Regeneration salt dose dictates water requirement and residual water level.

Understanding these guarantees accurate water level assessment.

Control Valve Settings

Adjusting the control valve settings critically influences the water level remaining in your brine tank after regeneration. The Brine Line Flow Control (BLFC) setting, combined with the valve’s programmed refill time, dictates the total water volume entering the tank.

This is calculated as BLFC (gpm) multiplied by refill duration (minutes). Using the manufacturer’s BLFC chart guarantees precise refill volumes tailored to system capacity. Setting BLFC too high causes excess standing water, while too low limits salt dissolution, impairing regeneration efficiency.

Mechanical float valves serve as overfill safeguards by cutting off refill at a set water height. However, fouled floats can malfunction, allowing overfill despite correct BLFC. Regular inspection and cleaning of float valves help ensure proper functioning and prevent pump shutdown.

Demand-initiated valves adjust refill time dynamically, affecting water volume per cycle. The white lobe pointer on the brine gear sets the salt volume and indirectly controls the refill time, influencing the water level after regeneration through the salt scale setting.

Always consult valve-specific manuals to align BLFC and refill timing for optimal post-regeneration water levels.

Salt Bridging Effects

Although salt bridging often goes unnoticed, it markedly disrupts brine tank water levels and regeneration efficiency.

A salt bridge forms a hard crust on top of the salt, isolating it from water and preventing proper brine formation. This can cause misleadingly high water readings after regeneration due to trapped water below the bridge.

Proper maintenance and monitoring of septic system water use can help minimize complications related to water level anomalies. You should be aware that high humidity and temperature fluctuations promote crust formation and water level anomalies.

Overfilling the tank encourages large salt masses that bridge and block brine circulation. Low-quality salt with impurities increases bridging risk and affects salt bed consistency.

Different salt types (solar vs. pellet) behave differently, impacting bridging and residual water levels. Regular inspection during refills helps identify and address bridging or mushing promptly to restore peak operation and ensure proper brine concentration.

Detecting and addressing salt bridging is essential to maintain accurate water levels and effective regeneration.

Common Causes of Excess Standing Water Post-Regeneration

If you’re seeing excess standing water after regeneration, it’s usually because of some issues with the brine draw. This can happen due to problems with the injector or control valve.

And, hey, don’t forget about the float valve—it might be malfunctioning and allowing the tank to overfill because it’s not shutting off the flow when it should. Regular maintenance of components made from chemical-resistant materials helps prevent such malfunctions.

Another thing to keep in mind is salt bridging. This is when you get a hardened crust that blocks the salt from dissolving properly. As a result, you’re not getting the right amount of brine production, which can lead to water accumulating.

So, it’s worth checking these components if you run into that issue! Also, a clogged injector can prevent the brine from being properly drawn into the mineral tank during regeneration, causing water to remain in the brine tank.

Incomplete Brine Draw

When you notice excess standing water after regeneration, incomplete brine draw often points to specific system issues. These problems prevent the system from properly drawing brine, leaving water levels higher than normal.

Key causes to check include:

Drain Line Restrictions: Corrosion or debris reduce flow rates, impairing the venturi effect essential for brine draw. The drain line port on the valve also contains a flow control orifice that regulates drain flow and can become a point of restriction. Proper maintenance of valves and lines, including installation of a check valve, can prevent backflow and ensure efficient drainage.

- Clogged Injector and Nozzle: Sediment buildup blocks suction, causing weak or absent drain flow during draw cycles.

- Brine Line Obstructions: Kinks, leaks at compression fittings, or improper routing restrict brine movement and suction.

- Salt Bridge or Mushing: Hardened salt crusts or salt slurries prevent salt dissolution, stopping brine formation.

Float Valve Malfunction

Inspect the float valve closely whenever you encounter excess standing water after regeneration. Mechanical failures like bent float arms or stuck floats can prevent proper sealing, causing continuous water fill. The float valve controls the water level in the brine tank by regulating the inflow during regeneration water level control.

Additionally, brine line seal issues such as damaged tubing or poor quick-connect seals disrupt vacuum and float operation. Mineral deposits and biofilm also impair float movement, resulting in overfill. Control valve faults may indirectly affect float positioning during cycles.

| Cause Category | Specific Issue | Effect on Water Level |

|---|---|---|

| Mechanical Failure | Bent float arm | Continuous water fill |

| Brine Line Seal Issues | Cracked tubing | Loss of vacuum, float remains high |

| Mineral/Deposit Fouling | Scaling on float surfaces | Float fails to close fully |

| Control Valve Faults | Skipped brine draw stage | Float doesn’t lower, excess water |

| Installation Misalignment | Improper float height setting | Tank retains excess water |

Salt Bridging Effects

Although salt bridging mightn’t be immediately obvious, it substantially impacts water levels after regeneration by guaranteeing salt from dissolving properly in the brine tank.

This creates a hard crust that isolates salt above from water below, causing weak brine and excess standing water. The presence of a salt bridge interrupts the brine solution contact with salt, thus preventing proper regeneration.

Common causes include:

Using rock salt or low-purity pellets with impurities that promote crust formation. High humidity or temperature fluctuations encouraging salt recrystallization. Overfilled tanks increasing mechanical pressure and compacting salt layers. Brine tanks lacking internal dividers or agitation mechanisms allowing static salt to crystallize.

Additionally, improper placement or malfunction of a bypass valve can affect water flow during regeneration and contribute to water level anomalies. Identifying salt bridging involves checking for a solid salt crust spanning the tank.

Regular maintenance, proper salt type, and controlled water levels help prevent this issue and guarantee efficient regeneration cycles.

Signs That Indicate a Problem With Water Levels

You’ll often notice specific signs that indicate a problem with your brine tank’s water level after regeneration.

If standing water remains at or above the salt level, it suggests incomplete brine draw, possibly due to valve failure or blockage. Ensuring the system has a dedicated power source can help prevent electrical issues that affect valve operation.

Continuous overflow through the emergency port signals float malfunction or persistent overfill. A brine tank full of water with dry salt on top typically indicates a salt bridge trapping air.

Conversely, very low or absent water may mean a kinked or detached brine line, clogged injector, or skipped fill cycles from controller errors. A common cause is when the brine line detached from the float prevents proper brine draw.

Salt crusts or mushing can block brine intake, causing abnormal water levels. Mechanical failures like clogged drain lines or faulty valves also manifest as persistent high or low water levels, disrupting normal regeneration function.

Step-by-Step Troubleshooting for Water Level Issues

When troubleshooting water level issues in your brine tank, start by verifying the regeneration cycle to ensure proper timing and operation of fill and draw stages. Initiate a manual regeneration and observe water drop within minutes. Confirm the brine fill stage occurs in the last 12 minutes with water inflow. This helps to prevent insufficient brine production, which can impair softening efficiency.

Next, inspect the float assembly for free movement and proper adjustment; clean or replace if faulty. The float valve mechanism plays a crucial role in controlling water supply to the tank by responding to water levels via a float ball.

Then, clean the brine line and connections by clearing clogs, checking for kinks, and verifying secure attachment. Finally, address tank obstructions by breaking up salt bridges and removing debris. Salt bridging or mushing can interfere with normal operation and cause water level abnormalities.

Verify valve and drain components for clogs or sediment buildup. Test brine line flow control washers and replace worn parts. Clean the brine well cylinder and safety float if needed. Monitor the entire cycle for irregularities in filling or draining.

Maintenance Tips to Keep Water Levels Optimal

To maintain ideal water levels in your brine tank, keep the salt level consistently between one quarter and no more than six inches below the tank top. Make sure salt remains a few inches above the water to promote proper brine concentration. Check salt levels monthly, especially if regeneration is frequent.

Avoid overfilling to prevent salt bridges, which can block water access; detect bridges by tapping the tank exterior and break them gently with a broom handle. Use high-quality salt pellets to reduce bridge formation caused by humidity or impurities. Regularly loosen encrusted salt and remove sludge at the tank bottom to prevent clogs.

Cleaning the brine tank also provides an opportunity to inspect valves and fittings for early signs of wear or leaks. Clean the tank every 6 to 12 months, with professional deep cleaning recommended every three years. Maintain valves and settings monthly alongside salt level inspections for peak operation.

Measuring and Recording Water Levels for Best Results

Maintaining ideal salt and water levels lays the foundation for effective brine tank performance. Optimal salt and water balance is essential for ensuring your brine tank operates efficiently. Precise measurement and consistent recording of water levels guarantee you can verify and adjust system operation accurately.

Use these methods to make certain peak monitoring:

- Measure water depth from the tank top using a tape or ruler for spot checks.

- Employ ultrasonic or pressure sensors for continuous, non-contact level monitoring. An external pressure sensor mounted on an inspection port provides reliable level data without tank penetration.

- Record measurements with date, time, method, and exact reference points for repeatability.

- Log static and post-regeneration levels, including salt dose and cycle ID for correlation analysis.

Regular calibration of sensors and redundant measurements help detect drift or failure. Detailed records enable you to interpret brine quality accurately and maintain efficient regeneration cycles.

Frequently Asked Questions

Can Water Hardness Affect Brine Tank Water Levels After Regeneration?

Yes, water hardness can indirectly affect brine tank water levels after regeneration. Harder water demands more frequent and intensive regeneration cycles, increasing brine usage and potentially leaving more residual water.

While hardness doesn’t directly raise water levels, it influences cycle frequency and brine strength, which can slow drainage or cause slight water retention. If you notice excessive standing water, check for mechanical issues rather than attributing it solely to hardness.

Is It Normal for Brine Tank Water to Have a Salty Odor?

Yes, it’s normal for your brine tank water to have a salty odor because it contains concentrated sodium chloride brine.

This saline smell is inherent to the solution. However, if the odor intensifies or persists between regenerations, it could indicate salt mushing, sludge buildup, or microbial growth.

You should inspect and clean the tank regularly, check the float valve, and guarantee proper flushing to prevent foul odors that suggest maintenance issues.

How Does Water Temperature Impact Brine Tank Water Depth?

Water temperature affects how quickly salt dissolves, which influences the effective brine concentration at a given water depth.

Colder water slows dissolution, so you might need slightly more water or longer soak times to maintain proper brine strength. This could potentially increase your target water depth.

Conversely, warmer water dissolves salt faster, allowing for standard water depths.

Adjusting water depth based on temperature guarantees peak regeneration and prevents weak brine formation.

Can Using Different Salt Types Change the Water Level After Regeneration?

You won’t believe how much salt type tweaks your brine tank’s water level!

Different salts dissolve at varying rates, so using pellet, solar, or rock salt can slightly shift water depth after regeneration.

Pellet salt dissolves faster, keeping water levels steadier, while rock salt may cause fluctuations or bridging, temporarily altering water amount.

Should Brine Tank Water Be Replaced Periodically or Only When Cleaning?

You should replace brine tank water periodically, not just during cleaning. Regular water changes prevent sediment buildup, bacterial growth, and salt mushing that impair brine efficiency.

Inspecting and replacing water annually or more often in wet tanks maintains peak salt dissolution and resin regeneration. If you notice odors, sludge, or performance drops, drain and sanitize immediately.

Following manufacturer guidelines guarantees consistent softener performance and prolongs system life.

Final Check: How Much Water Does Your Brine Tank Really Need?

So, if your brine tank looks more like a swimming pool after regeneration, don’t just sit there admiring the water feature. You should have just enough water to dissolve the salt, usually a few inches covering the salt bed.

Anything more means your system’s throwing a watery tantrum. Keep an eye on those levels, troubleshoot promptly, and maintain diligently. Otherwise, you’ll end up with a salty mess instead of smooth, softened water.