Last Updated on June 15, 2023

Have you ever wondered how your sump pump knows when to turn on and off? It’s a pretty creative process. And the answer lies in the sump pump float switch.

Sump pump float switches turn on and off a sump pump based on the water level in a sump pit. A buoyant float is attached to a switch that detects changes in water level.

When the water level in the sump pit rises, the float rises with it. As the float reaches a certain height, it triggers a switch mechanism that turns on the sump pump. Pumps remove water from the pit until the float returns to its initial position, indicating that the water level is back to normal.

Throughout this post, we’ll discuss how float switches work, what causes them to fail, and how to know when yours needs to be replaced.

How Does a Sump Pump Float Switch Work: 5 Factors

Understanding the mechanics behind sump pump float switches is key to comprehending their role in protecting our homes and businesses from water damage. The following explains the different components and how they interact for a sump pump float switch to work.

Overview of Sump Pumps and Float Switches:

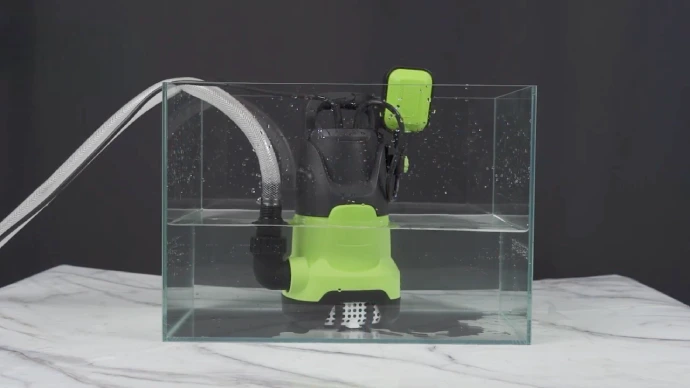

Dealing with flood damage in your home can be a nightmare, but with the help of a sump pump, you can rest easy knowing that your basement or crawlspace is protected.

This simple yet essential piece of equipment, equipped with an electric motor and a float switch, acts as your first line of defense against water accumulation.

The float switch situated in a sump pit helps detect water levels and kicks into action when the water level reaches a certain point, automatically starting the motor and pumping out excess water.

Once the water level is back under control, the switch shuts off the motor, ensuring your home remains dry and protected. This sump pump can safeguard your property and avoid costly damage from unwanted water buildup.

01. Sump Pump Float Switch Working Process

The float switch operates by a buoyant device attached to a rod or cable that links to the pump motor. As water levels rise in the sump pit, so does the buoyant float.

When the water reaches a particular level, the float switch triggers, activating the pump motor. The pump will then start pumping water out of the pit and away from the building. Once the water level drops below a specific point, the float switch lowers, and the pump motor turns off, completing the cycle.

This automatic operation guarantees that the sump pump system only operates when needed and provides efficient and dependable protection against water damage.

02. Position of the Float Switch

The accurate positioning of the float switch is critical to the proper functioning of a sump pump. The buoyant float should be attached to an arm and positioned within the sump pit or water reservoir.

As water enters the pit, the float rises with it. When the water level reaches a specific threshold, the float triggers the switch, activating the pump to begin pumping water out of the pit.

Also, the float switch’s position should be positioned so it can easily move up and down within the sump pit. The best position is achieved by ensuring the float can move freely without any obstruction.

If it is incorrectly positioned, it can lead to pump failure, which will ultimately cause flooding.

03. Triggering the Switch

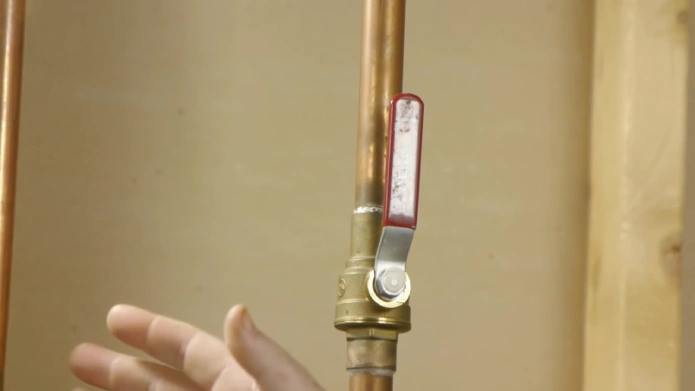

Sump pumps are triggered when the water level reaches a specific height within the pit. The user typically determines this height and it should be set according to the specific need.

When the water level reaches this threshold, the flotation mechanism lifts the buoyant arm to a level that activates the switch, signaling the pump to start.

It is essential to remember that if the sump pit water level height is too low, the float switch may not activate the pump. This could lead to severe damage in the event of a flood.

On the other hand, if it is set too high, the pump may work unnecessarily. Therefore, setting the sump pump float switch carefully is crucial to ensure optimal performance.

04. Deactivation of the Switch

There is as much importance to deactivating the sump pump float switch as activating it. Once the pump starts, it evacuates the water from the sump pit, lowering the water level.

As the water level drops, the flotation mechanism lowers with it. When the float reaches a certain lower threshold, it deactivates the switch, breaking the electrical circuit and stopping the pump.

Therefore, ensuring that the deactivation is set up correctly is crucial. If the float is positioned too high, the pump may keep running even after the water has been pumped out of the sump pit. This can cause pump damage, which can be expensive to repair.

On the other hand, if the float is set too low, the pump may stop too early, leading to potential flooding. Correct positioning of the sump pump float switch is vital to ensure the proper function of the sump pump, and it is recommended to have it checked and maintained regularly.

What Are the Types of Float Switches?

Float switches work based on the principle of buoyancy, where the position of a floating object changes with the liquid level. The two main types of float switches are:

Stem-mounted float switches

These switches, also known as vertical float switches, consist of a buoyant float attached to a stem. The stem is mounted vertically inside a tank or container, with the float moving up and down based on the liquid level.

The stem is connected to a switch mechanism activated or deactivated as the float reaches specific positions, indicating high or low liquid levels. Stem-mounted float switches are commonly used in applications where space is limited or in narrow tanks.

Cable-suspended float switches

These switches, also called horizontal float switches, feature a buoyant float attached to a cable or chain. The float moves horizontally along with the liquid level.

The cable or chain is connected to a switch mechanism triggered when the float reaches a particular position. Cable-suspended float switches are suitable for use in large tanks or where there is a need to cover a wider range of liquid levels.

How Do You Find a Quality Full Float Switch for Sump Pumps?

Finding a quality float switch for sump pumps can be challenging, but with the right research and knowledge, it’s possible to find a better one for a sump pump that meets your needs. The key is to look for material and build quality, switching capacity, size and fit, adjustable settings, and more.

When considering the material and build quality, look for switches made from durable materials that can withstand the sump pump’s moisture. It is also essential to consider the switching capacity, which will determine how much current can be handled by the switch.

Also, you should pay attention to the size and fit as some switches may not fit properly in certain sump pumps. Lastly, many switches have adjustable settings allowing users to customize their setup according to their needs.

To ensure you get the quality full float switch for your sump pump, it’s important to read reviews and compare different online models before purchasing.

You can also use online buying guides like ours on the best float switch for sump pumps, which provide detailed information on all aspects of choosing the right float switch. By doing so, you can rest assured that your purchase is of high quality and will work perfectly with your system.

What Causes Float Switch Failure in Sump Pump?

Float switch failure in sump pumps can be caused by several factors, including the incorrect configuration of the switch, poor maintenance, using a float switch that is not designed for the purpose, or one that is not adequately rated for the application.

- Incorrect configuration can lead to premature float switch failure due to improper installation and adjustment of the switch.

- Poor maintenance may also cause float switches to fail prematurely. This includes lack of cleaning or lubrication and overuse or misuse of the switch.

- Float switches should also be chosen with care. If a switch is not designed for use with a sump pump, it may fail prematurely.

How Do You Know If a Sump Pump Float Switch Is Bad?

One way to determine whether a sump pump float switch has failed is by filling your sump pit with enough water to raise the float until the pump kicks on. If the water level gets near the top of the pit, but the pump doesn’t activate, you may have a bad switch.

But if filling up your pit with water and triggering your pump lowers the water level in your pit close to empty, then your float might still be working correctly and just need an adjustment.

What level should a sump pump float switch be set at?

Setting the proper level for your sump pump float switch is crucial to prevent flooding in your basement or crawlspace. Industry standards suggest that the water level in the sump pit should be around 3 inches high, but this recommendation can vary depending on your pump’s specific model.

To ensure the efficiency of your sump pump, it’s vital to set the float switch at an appropriate height. If the switch is too high, your pump won’t turn on until the water level is too high, resulting in potential flooding. Conversely, if it’s too low, it can cause frequent pump cycling, which leads to burnout.

Understand Sump Pump Float Switches to Prevent Floods

A sump pump float switch may not seem like a crucial device, but it plays a significant role in protecting your home from water damage. The float switch keeps your basement or crawl space dry and safe by detecting high water levels and triggering the pump to remove the excess water.

Like any mechanical device, these switches can fail for various reasons, so it’s important to understand how they work and how to detect any issues. Regular maintenance and care can go a long way in ensuring that your float switch operates correctly and your home is protected from floods.

Don’t let a faulty float switch lead to costly repairs or permanent damage to your property. Take the necessary steps to keep it in top condition.