Last Updated on July 23, 2023

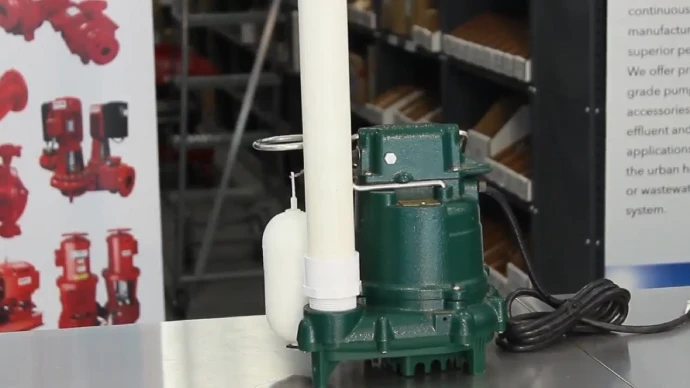

Do you know the real power behind a dry basement? It’s all due to sump pumps and their ability to protect homes from flooding. But what most people don’t realize is that these handy power machines require vents for their work properly.

The vent on a sump pump plays two significant roles. It lets air in and out, preventing air bounding. If your sump pump’s vent is blocked or clogged, your basement can suffer from flooding. And that’s why it is important to know how to vent a sump pump correctly.

Let’s see the crucial steps needed to vent your sump pump properly. We’ll also discuss why you should never skip venting your sump pump.

Why Does A Sump Pump Need A Vent: Simple Explanation

The sump pumps are primarily vented to prevent pressure buildup in the sump pit. When water is removed from a sump pit, the resulting vacuum or negative pressure can cause the pump motor to work harder and potentially burn out.

To prevent this scenario, the air must be allowed to escape through a vent. This allows pressure to be relieved and prevents damage to the pump.

Not only does this help with efficiency and ensures that any harmful gases produced by decaying organic matter in the water can leave the sump pit rather than accumulating and potentially causing harm or damage.

How Do You Vent a Sump Pump?

Venting a sump pump is essential for ensuring it works correctly and helps keep your home safe from flooding. Here’s a step-by-step guide on how to do just that. We’ll walk you through the entire process so you know your sump pump is always working well and ready to protect your basement.

Step 01: Choose the Location

When choosing a location for your sump pump’s vent pipe, it’s not just about functionality but also about minimizing any noise disruptions that may arise. Ensuring that the area is far from doors and windows can make a massive difference.

Also, you don’t want to deal with blockages caused by debris from outside, which can lead to clogs and damage to your system. Accessibility is another critical factor, as the pipe needs to be easily installed without cutting through walls or floors.

With all these considerations in mind, it’s vital to assess whether the space is sufficient for a proper installation to maximize the efficiency of your sump pump system.

Step 02: Install the Vent Pipe

It’s essential to make sure the pipe is at least 1 1/2 inches in diameter to handle large amounts of water. But it doesn’t stop there. The pipe must also extend at least 12 inches above the roof line with a minimum slope of 1/4 inch per foot.

This will allow water to flow smoothly without clogging or getting stuck. Lastly, be cautious of horizontal runs. Without the proper slope, water can flow backward, potentially causing damage to your home. A little attention to detail during installation can prevent headaches down the road.

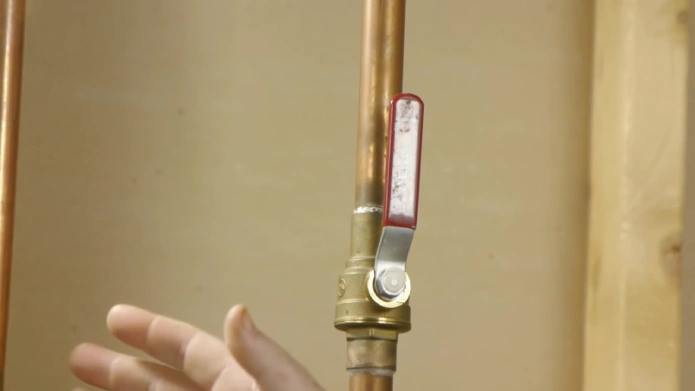

Step 03: Secure the Vent Pipe

After installing a sump pump’s vent pipe, secure it properly to both the sump pump and wall using clamps or brackets.

The clamps should fit snugly around both surfaces and make sure they are tightly fastened together so they do not come apart over time due to vibrations or other movements caused by changing temperatures or pressure levels in your home.

To further secure your installation, use sealant around all joints between pipes and fittings and between pipes and walls where applicable. This will help keep unwanted water out of your basement and provide superior long-term performance for your sump pump system.

Step 04: Install a Vent Cap

One integral part of this is installing a vent cap on the pipe. This small but mighty addition prevents debris and critters from getting into the pipe, which can cause clogs or damage to the pump. It’s essential to position the cap at 12 inches or higher to ensure proper ventilation.

But installation is not just about placement, it’s also about making sure the cap is securely sealed around the pipe to prevent air leaks. One easy way to do this is by using caulk or sealant around the cap’s edges.

And for an extra secure fit, use stainless steel screws to attach the cap firmly. With a well-installed vent cap, you can rest easy knowing that your sump pump is operating safely and efficiently.

Step 05: Test the Sump Pump

Testing the sump pump is essential to ensure it is functioning correctly.

First, check for proper voltage between all wires connected to the pump’s motor. Then, run water into the sump pit until it reaches its average operating level.

Watch for any issues, such as leakage from either end of the discharge pipe or improper operation of electrical components.

If everything appears to be working correctly, you can then check for proper discharge through the vent pipe by running more water into the pit and verifying that it exits out of the end of the vent pipe.

Step 06: Check the Vent Pipe Periodically

It’s important to periodically check your sump pump’s vent pipe for any obstructions or clogs which might cause poor performance or damage to your system.

Both ends of the vent pipe should be checked for any blockages such as leaves, twigs, dirt, or debris which may have built up inside over time at the bottom where the water exits your home and at the top where air enters.

If anything has blocked off either end, remove it carefully with a brush or vacuum cleaner before running more water into your sump pit. Also, you should ensure all connections are secure and free from leaks before testing again.

Does your sump pump pit need a vent pipe?

A vent pipe installed on your sump pump pit is highly recommended to ensure your pump works properly and remains safe. A vent pipe serves several purposes.

It allows any accumulated gases, such as radon and methane, within the pit to escape safely rather than building up and becoming hazardous to your health or emitting unpleasant odors.

Also, air circulation within the pit is promoted by installing a vent pipe that can help limit mold and mildew growth and regulate temperature levels so that the pump does not overheat.

Ultimately, investing in a good quality vent pipe for your sump pump pit can save you time, money, and effort in the long run by ensuring that your system runs smoothly with minimal maintenance necessary.

Does every sump pump need a vent?

It depends on several factors. If the discharge pipe from your sump pump has a lot of turns or runs long distances, then having a properly-vented system is essential, as an airlock can form without it.

Local building codes may also require that all sump pumps have vents installed. So it’s essential to check with your local authority before making any decisions about installation.

Even if you don’t have any specific requirements regarding vents, having one installed is often beneficial for your pump system’s optimal performance and efficiency.

How often should you check your sump pump vent?

It is recommended to check your sump pump vent at least twice a year to ensure it has not become blocked or damaged.

Checking for blockages is particularly important because if a vent becomes blocked, it could accumulate water pressure, damaging pipes or other components of your plumbing system.

Regular maintenance and cleaning will also help extend the life of your sump pump and keep it functioning properly over time.

Secure Your Home from Water Damage with a Well-Ventilated Sump Pump System

It’s essential to have a properly ventilated sump pump if you want your home to be safe and secure against potential water damage. With an effective ventilation plan in place, the equilibrium of air pressure is maintained while excess water efficiently exits. It’s one more way to give yourself peace of mind.

Without it, you run the risk of air locks occurring and water not being drained efficiently. And during flooding periods, a vent can help keep your basement dry and prevent water from seeping into your home’s foundation.

Following the above mentioned steps, you can easily install the vent and prevent air-bounding issues. By ensuring your sump pump is properly vented, you can rest assured that any water accumulation in your basement will be handled efficiently.