Last Updated on May 10, 2023

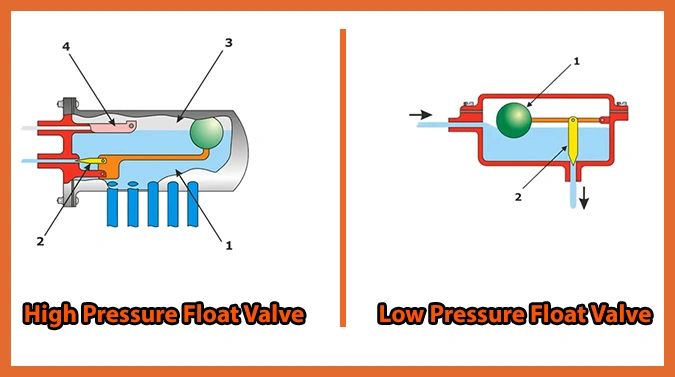

A hollow cylindrical pipe floats a float ball on a liquid surface with an automatically regulated float valve, rising and falling when the liquid level changes. There are two types of float valves: high pressure and low pressure.

Float valves with high pressures are usually used in industrial applications, where temperatures and pressures are higher, while float valves with low pressures are more common in household settings. But what are the differences between high and low pressure float valves?

Toilets, sump pumps, and irrigation systems all use floating valves, but choosing the right one is essential. Find out how high-pressure and low-pressure float valves differ and how to choose the correct one.

What is a Low Pressure Float Valve?

A low-pressure float valve is a specialized valve designed to open and close quickly to prevent water damage. The valve is often used in cisterns, tanks, and other water storage containers. When the water level in the container drops, the valve will open and allow water to flow in.

As the water level rises, the valve will close and prevent overflows. The valve’s quick-acting nature helps prevent severe water damage in case of a malfunction. Also, the valve is often equipped with a larger hole that allows for more rapid filling of the tank or cistern. This feature is handy when the water pressure is high.

What is a High Pressure Float Valve?

A high-pressure ball valve is a device that helps regulate water flow in a cistern or tank. The valve has a small hole that allows water to flow through. When the cistern is full, the float rises and shuts off the water flow, preventing overflow.

This type of valve is often used in high-pressure systems where a large volume of water is required, such as in industrial settings. In addition to its practical applications, the high-pressure float valve can also be used as a decorative element in plumbing fixtures.

What is the Difference Between High and Low Pressure Float Valves?

Understanding high and low-pressure float valves are essential for anyone maintaining a plumbing system. Here are some key differences:

Float Valve Color

High-pressure float valves are usually white, while low-pressure float valves are usually red. The color difference indicates high-pressure float valves operate at higher pressures than low-pressure float valves.

This color coding helps prevent accidental mixing of different float valves, which could lead to serious damage or even explosions. In addition to their different colors, high and low-pressure float valves also have different maximum pressure ratings.

Also, these color code helps plumbers and other professionals to quickly and easily identify the type of float valve they are dealing with. While it may seem a small difference, this simple innovation can save time and hassle when working with plumbing systems.

Size of the Valve Nozzle

Different types of float valves can be used depending on the application’s needs. One key difference between these two float valves is the nozzle size. On a high-pressure float valve, the nozzle is typically smaller, with a hole that measures 2 to 3 millimeters in diameter.

The nozzle on a low-pressure float valve is typically larger, with a hole measuring 5 to 8 millimeters in diameter. This difference in nozzle size allows each type of float valve to function optimally in its intended pressure range.

Maximum Operating Pressure

The answer is the force required to open and close the valve. High-pressure float valves are designed to withstand higher operating pressures, approx 232.06 PSI. A strong piston opens these valves by overcoming the pressure of water.

Low-pressure float valves are only designed to withstand pressures up to 4.3 PSI. These valves use a lighter float pulled open by the water pressure. Thus, low-pressure float valves are unsuitable for high-pressure applications.

Installation Place

High-pressure float valves are commonly installed in commercial and industrial applications where the water pressure is higher than average such as power plants, where temperatures and pressures can be very high.

Low-pressure float valves are designed for use in residential settings that can withstand lower temperatures and pressures. They tend to be found in household settings, such as plumbing systems, where pressures and temperatures are typically lower.

Generated Noise

Noise is generated differently by high-pressure float valves than low-pressure ones. High-pressure float valves tend to be much louder than low-pressure float valves due to the increased forces they must withstand.

This can be beneficial in many applications, as the noise can warn that the pressure is getting too high. Also, high-pressure float valves are often constructed of heavier-duty materials to prevent them from being damaged by increased pressure.

These are the key differences between high-pressure float valves and low-pressure float valves. Consider these things when choosing the suitable float valve for your needs.

What are the Purposes of a Float Valve?

The purpose of a float valve is to prevent overfilling or overflow of a tank. Float valves work by sensing the liquid level in a tank and automatically shutting off the flow of liquid when the level gets too high.

This can be useful in various applications, such as preventing overflows in sewage treatment plants or ensuring that water tanks do not get too full. Float valves can divert liquid to another location when a tank needs to be refilled from a nearby source.

Whatever the application, float valves provide an important safety function by preventing liquids from spilling into areas where they could cause damage or pose a danger to people.

What Float Valve Would You Use on a Low Pressure Water System?

The low-pressure floating ball valve is the most common type of float valve used in low-pressure water systems. It consists of a ball with a hole in the center attached to a rod. The rod is connected to a lever, which opens or closes the valve depending on the ball’s position.

When the water level rises, the ball floats and lifts the rod, which closes the valve. As the water level drops, the ball falls, and the valve opens. This type of float valve is simple, reliable, and easy to maintain. Also, it is relatively inexpensive and can be used in various applications.

What is the Maximum Pressure Handled by High Pressure Float Valves?

High-pressure float valves are an essential component in many industrial and commercial applications. They can open and close at high pressures, up to 232 PSI. This enables them to regulate the flow of water or other liquids in various settings, from power plants to factories.

High-pressure float valves are typically opened by a strong piston that can overcome the force of the water pressure. This allows the valve to open and close quickly and efficiently, without leaking.

A high side float valve is usually equipped with a safety release mechanism that prevents the valve from opening at too high a pressure. This helps to protect the valve from damage and ensure that it operates correctly.

How do You Buy a High-Pressure Float Valve for Water Tanks?

When purchasing a high-pressure float valve for water tanks, it’s important to research and compares different products in terms of their specifications and features.

A wide variety of float valves are available on the market. For your convenience, we have reviewed some of the top-rated float valves for water tanks out there.

Our reviews detail the specifications and features of each valve, giving you a clear understanding of what each product has to offer.

How Much Pressure Can a Low Pressure Float Valve Hold?

The pressure that a low side float valve can hold varies depending on the manufacturer and the specific model of the valve. But, these valves can generally handle pressures up to 4.3 PSI. Their floats are lighter and are pulled open by water pressure.

Float valves with a low pressure are therefore unsuitable for applications at high pressures. If you are looking for a valve that can handle higher pressures, you will need to choose a different type of valve. Regardless, a low-pressure float valve may be a good option if your needs are relatively low-pressure.

How Does a Double Acting Float Valve Work?

Double-acting float valves are used in various applications, from industrial to residential. They are often used in tanks that need to maintain a consistent liquid level, such as reservoirs, holding tanks, and sump pumps.

Unlike regular float valves, which have only one float, double-acting float valves have two floats. This allows the valve to control the liquid level more precisely. The upper float turns the valve off when it reaches a certain level, and the lower float turns it on when it falls below that level.

Thus, double-acting float valves can maintain a consistent level of liquid in a tank, even if there are sudden changes in demand. Also, they are less likely to overflow or run dry than regular float valves.

While they are more expensive than regular float valves, double-acting float valves can provide significant benefits in terms of accuracy and reliability.

Which applications are there for high- and low-pressure float valves?

High-pressure float valves are commonly used in industrial and commercial applications where a high degree of accuracy is required. They are often used to control the level of liquids in tanks or reservoirs and can be found in a wide range of industries, from food processing to water treatment.

Low-pressure float valves are typically used in residential and light commercial applications, such as toilets and irrigation systems. They are also used in some industrial applications, such as cooling towers.

But the main application of low-pressure float valves is in plumbing, which regulates water flow in pipes. While they are not as accurate as high-pressure float valves, they are still effective in controlling the liquid level in a tank or reservoir.

Despite their different applications, both high-pressure and low-pressure float valves share one common goal: to provide precise control over the liquid level in a system.