Last Updated on May 22, 2023

Have you ever wondered if a gas ball valve could be utilized in waterworks? It’s an issue that plumbers and pipefitters regularly face. While gas valves are the standard for gas piping, they can also effectively moderate liquid flow.

Before utilizing a gas ball valve for water, ensure it is compatible with your supply system and rated for use. Shut off the area’s water source before installation to prevent any accidents or damage.

Once installed, carefully turn on the supply and check all connections have been secured correctly and there are no leaks present. Finally, test its operation by opening/closing the valve to verify proper functioning.

Ready to learn the ins and outs of gas ball valves for water systems? This post is perfect for both experienced professionals in the plumbing, as well as those looking to take on their own DIY projects. Let’s explore this important topic together.

Can You Use a Gas Ball Valve for Water: Check The Operation

Installation of the Gas Ball Valve

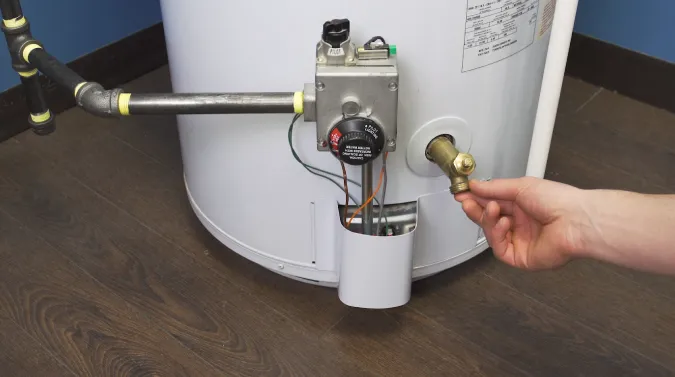

- Start by carefully examining the gas ball valve before installing it in the system. Make sure all of the components are present and in good condition.

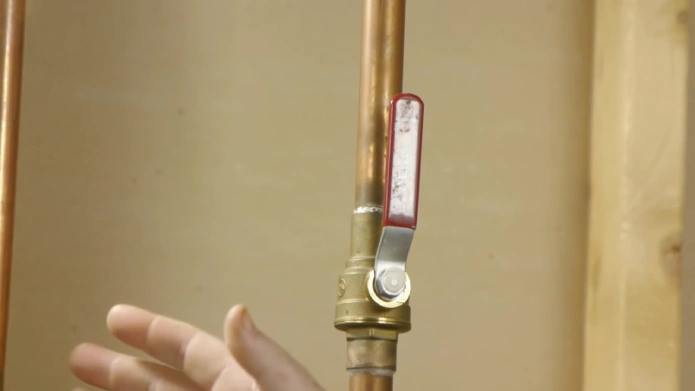

- Locate the valve in its desired position, taking into account any existing piping or other components that may be affected. Use a wrench to secure the valve firmly in place with bolts if necessary.

- Connect one end of your supply line to the side of the valve labeled “inlet” using a wrench and appropriate fittings. At this point, you can also attach an isolation flange, if needed, between the valve and supply line.

- Connect a flexible hose from the side labeled “outlet” on the valve to your system outlet location. Once again, verify a good connection with a wrench and appropriate fittings as required.

- Using an adjustable wrench, open up both ends of your supply lines for flow testing purposes. You should immediately begin to see gas flow through them. If nothing is happening, there may be an issue with your connections or valves, so double-check for any leaks or blockages first.

Operation of the Gas Ball Valve

Before operating the gas ball valve, make sure that the two ends of your supply lines have been opened up, and no leaks are present in either one otherwise, you risk damaging not only your equipment but also potentially dangerous explosions

The gas ball valve should now be ready for operation.

- Turn it clockwise until it is fully open (the handle should be aligned with the piping). As soon as you do this, you will hear air start flowing throughout both sides of your supply lines simultaneously this indicates everything is working correctly.

- After some time has passed (at least 10 minutes), shut off the flight valves by turning them counterclockwise until they are fully closed (the handle should again align with the piping).

This process ensures that no residual air remains inside either pipe after shutoff, which could cause damage over time due to pressure buildup.

Maintenance of the Gas Ball Valve

It’s important to perform regular maintenance on both rears of your supply lines as well as on all other components connected to them, such as valves and regulators – this keeps everything running smoothly and reduces potential problems down the road.

- Inspect all connections for leaks or blockages every few months, especially during periods when usage is higher than usual, like summertime, when temperatures tend to rise quickly, causing more stress on pipes or fittings or valves, etc.

- Doing so will help catch any issues early before they become more serious later on.

- Check all safety features regularly (e.g., sensing detection devices) these are designed to prevent accidents in case something goes wrong while operating, so they need attention too.

- Also, keep an eye out for any corrosion, which could lead to clogging or reduced efficiency if not taken care of quickly enough.

- Finally, replace any worn-out parts whenever necessary; we suggest doing so every year or two, depending on usage levels and environmental conditions around where you live/work, etc.

This way, you can rest assured knowing that everything is running optimally at all times without worrying about potential breakdowns later down the road due to unexpected deterioration.

Overview Of The Types Of Valves That Are Commonly Used In Water Systems

Alternatives to a gas ball valve for the water system are plentiful and varied. While the traditional gas ball valve is still the most commonly used type of valve in water systems, there are many alternative solutions that can be employed depending on the specific requirements of the system.

The Gate Valves

Gate valves and globe valves are frequently used in water systems as an alternative to gas ball valves. Gate valves are designed with a gate-like disc that can be raised or lowered to block the flow of water through the pipe.

It is a linear valve, meaning the gate travels up and down in the pipe. When the gate is raised, it allows for full open flow. When it is lowered, it completely blocks the pipe. This makes gate valves ideal for applications that require either fully open or fully closed settings.

The Globe Valves

Globe valves are different from gate valves in several ways. The most noticeable difference is that they feature a curved or contoured disc instead of a flat one, allowing them to control fluid flow more precisely by adjusting their angle within the opening.

Unlike a linear valve, this allows for various levels of throttling between fully open and fully closed positions. Globe valves are also usually installed horizontally, making them less prone to clogging problems due to sediment build-up compared to vertical models like gate valves.

Globe valves work best in applications that require medium-to-high pressure and where regulation of flow rate is necessary.

The Diaphragm Valve

One type of alternative is a diaphragm valve. This type of valve uses a flexible diaphragm to open or close off a pipeline depending on pressure or other indicators within the system.

Diaphragm valves are valued among engineers for their low-maintenance, compact design, and good resistance to corrosion and erosion.

They are often used in process control applications, such as those involving odors or vapors, due to their ability to provide tight shutoff even at very low pressures.

The Butterfly Valve

Butterfly valves are another popular alternative solution for water systems. These large circular valves feature an internal disc that rotates perpendicular to the flow of fluid to open and close it off.

They tend to be more economical than other valves, especially when a high-pressure application is required. They offer more reliable sealing than gate or globe valves when used in low-pressure applications due to their metal-to-metal seat contact points.

Butterfly valves also have a relatively short stroke time compared to other valves, making them ideal for quick shutoff or throttling applications where speed is of utmost importance.

The Plug Valve

Plug valves are another valuable option when it comes to controlling fluids within water systems. Unlike gate or butterfly valves which use a linear motion, plug valves use a rotational motion that allows for a tighter seal than gate or butterfly accessories would typically provide.

Due to this tighter seal, these types of valves can be employed in higher-pressure applications without fear of leakage along the edges, which would occur with other types of valve mechanisms.

Additionally, because plug valves operate with a rotational mechanism, plug valves require less maintenance work than those with more complex designs, such as gate or butterfly counterparts.

The Pilot Operated Valve

Finally pilot operated check valves are another useful substitute for conventional ball valve systems used in water networks. These self-operated devices allow fluid movement through them under normal conditions.

However, they will automatically close if backflow occurs at any point further downstream from where they’re installed, effectively preventing further damage from occurring within the system itself as well as protecting any sensitive components further along its length.

As an added bonus pilot operated check vents also allow users greater control over pressure levels within their systems; allowing them.

Risks and Limitations of Gas Ball Valve Use in Water Systems

Potential Risks

We can identify several potential risks associated with using a gas ball valve for water systems.

- First, the valve may leak due to wear and tear on its seal, which could lead to pressure loss and the risk of contaminated water entering the system.

- Second, if the valve is not sized correctly, it may not be able to handle sudden pressure changes or surges within the system; this could cause failure or extreme temperatures in some areas of the system.

- Third, since gas ball valves must be manually operated in order to open or close them, there is a risk that they will be left open too long or closed too quickly, resulting in back-flow or other mechanical problems.

- Finally, improper installation of a gas ball valve can also cause damage to pipes and fittings due to misalignment or incorrect torquing when tightening components.

Potential Limitations

In addition to the risks of using gas ball valves with water systems, there are certain limitations that should be considered as well.

- Many types of gas ball valves have limited temperature ratings and may become damaged if exposed to higher temperatures than what is recommended by the manufacturer.

- Because these valves have manual operation only, they cannot provide automated control over flow rates within a system. Therefore, they are generally not suitable in applications where precise flow control is needed.

- Gas ball valves are typically less efficient than other types of valves when it comes to flow control; this makes them less efficient than other options in terms of energy usage and cost savings over time.

- Finally, since these valves require more frequent maintenance and adjustments than other types of valves do (due to their manual operation), additional costs must be taken into account when choosing between different types of valves for water systems.

Can You Use Gas Press Fittings on Water?

Water can be used with gas press fittings. Gas press fittings are designed to join pipes together securely and quickly without having to solder them or rely on traditional threaded connections.

These press fittings work by using an internal O-ring and crimp ring system that allows two pieces of pipe to be joined together with great force, creating an extra tight and secure connection between them.

When used with cold or hot water, these fittings provide excellent resistance against leaks while being extremely easy to install. Additionally, since they don’t require soldering or any other heating element during installation, they are extremely safe to use on potable water lines.

Can You Use a Gas Connector for Water?

You cannot use a gas line connection for water. Gas connectors are designed specifically for connecting household appliances such as stoves and furnaces to the gas line in your home safely and securely.

It is not recommended to use a gas connector on a domestic supply line carrying cold or hot water. This could potentially cause serious damage due to corrosion or leaking if the wrong type of materials were used for the connection process.

Furthermore, gas connectors have different pressure ratings than those required for plumbing applications involving domestic supplies such as potable water or cold water lines. Therefore, it would not be suitable for this purpose at all.

Is There a Difference Between Gas and Water Fittings?

There is a contrast between gas and water fittings due to the different pressure ratings required by each application type (gas vs. water). Gas fittings typically need higher pressures than those used by household utilities such as cold or potable water lines.

Therefore, they would not be suitable if one were attempting to make connections between these two types of systems without considering safety measures first (such as using appropriate seals).

Materials used in connecting these two types of supply systems should also be carefully considered since some materials may not be compatible with certain liquids/gasses depending on their chemical properties (i.e., metals like brass may corrode when exposed to certain glasses).

Final Thought

Using a gas ball valve in a water system can provide superior performance and safety when compared to other types of valves. Still, it must be done with care due to the potential risks and limitations associated with it.

Before installing one into your system, make sure you understand the installation process and any necessary maintenance steps that need to be taken to ensure its continued safe operation.

Additionally, if you’re considering using one for hot water applications or connecting them up with gas press fittings or connectors, then make sure you consult a professional before proceeding any further.

With proper care and consideration taken during its installation and usage, you should have no problems getting great performance from your gas ball valve for many years.