You should install water hammer arrestors within six feet of pumps, valves, and quick-closing devices where sudden flow changes cause pressure surges. Also, place them at pipe direction changes like vertical risers or bends to absorb shocks effectively.

For branch lines under 20 feet, position arrestors near the last fixture. Longer runs may need multiple units at high points and near the valve source. Proper sizing and orientation matter too. Further guidance will make certain precise placement and installation.

Key Takeaways

- Install water hammer arrestors within six feet of pumps, valves, or devices causing rapid flow changes to absorb shock effectively.

- Place arrestors at pipe direction changes, such as pump risers or vertical offsets, to reduce pressure spikes from flow direction shifts.

- For branch lines under 20 feet, position arrestors near the last fixture; longer branches require arrestors near pumps and at high points.

- Use angle-type arrestors as elbow replacements near valve origins for bidirectional shock suppression and optimal performance.

- Mount arrestors vertically on horizontal supply lines to maintain air chamber function and ensure airtight, secure installation.

What Is Water Hammer and Why Arrestors Matter?

Although you mightn’t notice it immediately, water hammer creates a sudden pressure surge in your plumbing system when a valve or faucet closes abruptly.

This rapid closure causes the flowing water to decelerate suddenly, generating a shock wave that travels through the pipes. If unaddressed, this pressure spike can damage fittings, joints, and appliances, leading to leaks or system failure.

Installing water hammer arrestors mitigates these effects by absorbing and dissipating the surge energy, preserving pipe integrity. Arrestors function as shock absorbers, using compressed air or a spring mechanism to cushion the impact.

By strategically placing these devices near valves or fixtures prone to abrupt shutoff, you safeguard system longevity and reduce noise. Understanding this mechanism helps you prevent costly repairs and maintain plumbing performance effectively.

In addition, choosing components that are compatible with your system’s pressure and flow requirements ensures optimal protection and efficiency.

Choosing Water Hammer Arrestor Locations Near Pumps and Valves

When it comes to installing water hammer arrestors, it’s really important to place them as close as you can to the pump or valve where the hammer starts. This way, they can do their job of absorbing shock effectively.

Plus, putting the arrestor near isolation or check valves can really help reduce those pressure spikes that happen when the flow changes quickly. Ensuring proper placement can effectively mitigate issues caused by rapid valve closure and protect your plumbing system.

Proximity To Pump

When installing water hammer arrestors near pumps and valves, positioning them close to the source of the hammer is critical to effectively mitigate pressure surges.

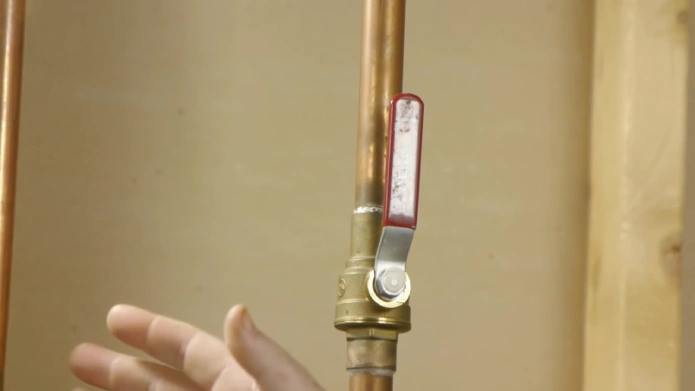

You should mount the arrestor within six feet of these components, ideally at pipe direction changes like the top of a pump riser.

This placement guarantees rapid absorption of shock waves generated by quick valve closures or pump starts and stops.

For branches under 20 feet, place the arrester near the last fixture or at the end of the line to prevent reflected surges.

Always verify the arrestor size matches the line diameter and system pressure.

Install it in an upright or horizontal orientation per manufacturer guidelines.

Accurate proximity prevents system damage and noise effectively.

For optimal system performance, it is also important to consider the check valve size to maintain proper function and efficiency.

Valve-Originated Hammer

Since valve-originated water hammer results from rapid valve closures causing pressure surges, installing water hammer arrestors close to these valves is essential to minimize shock impacts.

Position arrestors on the supply side within the last 5% of the line length, especially near isolation or check valves. For short branches under 20 feet, place arrestors at the end near the last fixture.

Install arrestors at pipe direction changes, such as pump risers, to mitigate pressure spikes. Make certain vertical mounting on horizontal lines for peak performance.

- Mount arrestors within 6 feet of the valve causing noise or shock.

- Use angle-type arrestors to replace elbows for bidirectional suppression.

- Select arrestor size per pipe diameter and system pressure.

- For multiple valves, install arrestors near each source of hammer.

- Confirm airtight installation and test for leaks post-installation.

In systems involving pumps, it is also important to consider installing a check valve to prevent reverse flow and reduce wear on components.

How to Place Water Hammer Arrestors at Pipe Bends and Direction Changes?

At pipe bends and direction changes, installing water hammer arrestors directly at or near these points effectively mitigates pressure surges caused by sudden flow alterations.

You should position arrestors close to elbows, tees, or risers where flow velocity changes abruptly. For serial elbows, place an arrester at the first bend after the check valve to suppress bi-directional shock.

| Location Type | Recommended Placement |

|---|---|

| Single Bend | At or immediately after elbow |

| Multiple Bends | First bend after valve, plus high points |

| Direction Changes | Near pump risers or vertical pipe offsets |

This method guarantees rapid absorption of hydraulic shock, minimizing noise and pipe stress through precise arrester placement at critical hydraulic change points. Using quiet check valves in combination with water hammer arrestors can further reduce noise and pressure fluctuations within the system.

How Close to Install Water Hammer Arrestors Near Fixtures?

Near fixtures, you should install water hammer arrestors within six feet of the valve or device causing the noise to guarantee effective suppression of pressure surges.

Positioning arrestors close minimizes the volume of water affected by sudden valve closure, reducing shock waves. Consider these key points for proper placement:

- Mount arrestors at washing machine outlet boxes or shut-off valves.

- Install on hot and cold supply lines of quick-closing valves.

- Place upstream from devices like dishwashers, lavatories, and toilets.

- Make certain proximity to valves in tubs, showers, and ice makers.

- Maintain vertical or horizontal orientation per pipe layout for peak function.

Before installation, always verify the water pressure regulator valve to ensure the system operates within safe pressure limits.

Placing Water Hammer Arrestors on Branch Lines and Multiple Fixtures

When managing branch lines and multiple fixtures, you’ll need to strategically place water hammer arrestors to guarantee effective shock absorption throughout the system.

For branches 20 feet or less, install one arrester within 6 feet of the last fixture. For longer branches, place arrestors near the pump or valve causing the hammer and at high points.

On multiple-fixture branches, position arrestors between the last two fixtures. This method optimizes protection while minimizing material and labor costs.

| Branch Length | Arrestor Position | Reason |

|---|---|---|

| ≤ 20 feet | End of branch | Covers last fixture shock |

| > 20 feet | Near pump & high point | Controls severe hammer |

| Multiple fixtures | Between last two | Balances pressure fluctuations |

| Serial elbows | First bend after valve | Mitigates directional shocks |

First check water pressure as high pressure can exacerbate water hammer and influence arrestor placement.

How to Size and Pressurize Your Water Hammer Arrestor?

Since proper sizing and pressurization directly impact the effectiveness of your water hammer arrestor, you need to carefully select the correct model and set its pressure according to your system’s requirements.

Start by referencing manufacturer sizing tables (I-A/I-B) to match your system pressure, typically up to 65 psig. Pressurize the arrestor to 30-50% of your normal working pressure to guarantee peak shock absorption.

For systems with fluctuating pressures, use multiple arrestors with varied pressures to bracket the range. Choose ASSE 1010 certified units; AA-size models provide equal capacity regardless of connection type.

For long or industrial lines, consider larger volume arrestors, such as 200 cubic inch.

- Consult sizing charts per system parameters

- Set arrestor pressure to 30-50% of working pressure

- Use multiple arrestors for variable pressure systems

- Select certified AA-size for standard applications

- Opt for larger volume units on extended lines

Ensure that any associated valves, like water pressure regulators, are installed in the correct orientation to avoid debris collection and containment issues that can impair system performance.

How to Install Water Hammer Arrestors Vertically or Horizontally?

When you’re installing water hammer arrestors, it’s usually best to mount them vertically on horizontal supply lines. This setup helps ensure that the air chamber works at its best.

Now, if you need to install them horizontally, that’s totally doable too! Just make sure you have secure fittings and that everything is aligned properly. Otherwise, you might lose some performance.

If you can, try to position the arrestor upright, with its long axis vertical. This way, you’ll maximize its ability to absorb shocks effectively. It’s all about keeping things running smoothly!

Also, consider that positioning and design can impact the noise level of your plumbing system, so proper installation helps reduce unwanted sounds.

Vertical Mounting Benefits

Although water hammer arrestors function effectively in both vertical and horizontal positions, mounting them vertically on horizontal supply lines offers distinct advantages. This ensures peak air chamber performance and prolongs device lifespan.

When installed upright, air chambers remain properly positioned to absorb pressure surges, preventing premature failure. You’ll also benefit from easier inspection and maintenance access.

Key vertical mounting benefits include:

- Maintains air damper function by keeping air chambers upright

- Reduces moisture accumulation inside arrestor, limiting corrosion

- Enhances pressure surge absorption efficiency

- Simplifies leak detection and servicing

- Aligns with manufacturer recommendations for Accumutrol-style arrestors

Proper installation techniques are crucial, similar to the careful positioning required when installing check valves in plumbing systems to ensure optimal function and prevent issues.

Horizontal Installation Tips

Whether you choose vertical or horizontal installation, positioning water hammer arrestors correctly guarantees peak function and longevity.

When installing horizontally, make sure the arrestor aligns with the pipe’s axis to maintain proper internal operation.

Use fittings that replace existing elbows, allowing the arrestor to fit flush without introducing stress points.

Secure the arrestor firmly with appropriate supports to prevent vibration-induced loosening.

Confirm the connection is tight; hand-tighten, then apply a quarter-turn with a wrench.

Avoid installing where sediment or debris may accumulate, which can impair function.

Horizontal mounting works well on supply lines running parallel to flooring or ceilings, facilitating easier access for maintenance.

Always test for leaks after installation and verify the arrestor’s orientation matches manufacturer specifications to preserve its shock-absorbing effectiveness.

Proper Positioning Guidelines

Maintaining correct orientation is key to guaranteeing water hammer arrestors function reliably over time. You can install them vertically or horizontally, but some guidelines help maximize efficiency.

For horizontal supply lines, vertical mounting is generally preferred. If using angle-type arrestors, replace pipe elbows to enable bidirectional suppression. Accumutrol series units require upright positioning with their long axis vertical. Air chambers must point upward to maintain air damper functionality.

Consider these positioning tips:

- Mount vertical arrestors on horizontal pipes for peak performance.

- Use angle-type arrestors as elbow replacements for directional flow control.

- Position Accumutrol models upright, long axis vertical.

- Guarantee air chambers point upward to retain air cushioning.

- Test installations for leaks and accessibility for maintenance access panels.

Following these precise placement methods guarantees long-term, effective water hammer mitigation.

Step-by-Step Water Hammer Arrestor Installation Guide

When installing a water hammer arrestor, start by shutting off the main water supply and relieving system pressure to guarantee safety. Drain the affected lines to prevent water spillage.

Select the correct arrestor size based on pipe diameter and pressure ratings. Thread the arrestor onto the valve or fitting, hand-tighten, then apply a quarter-turn with a wrench.

Mount the arrestor vertically on horizontal lines or according to manufacturer specifications. After installation, restore water supply and inspect for leaks.

Test the system by activating quick-closing valves to assure noise suppression.

| Step | Action |

|---|---|

| 1. Preparation | Shut off water, relieve pressure, drain |

| 2. Installation | Thread arrestor, tighten, mount vertically |

| 3. Testing & Inspection | Restore water, check leaks, test operation |

Frequently Asked Questions

Can Water Hammer Arrestors Prevent Damage to Appliances?

Yes, water hammer arrestors can prevent damage to your appliances by absorbing the shock waves caused by sudden valve closures.

By installing them near quick-closing valves like those on washing machines or dishwashers, you reduce pressure surges that might otherwise stress pipes and appliance components.

Properly sized and positioned arrestors maintain system integrity, minimize noise, and extend appliance lifespan by preventing repeated mechanical shocks within your plumbing network.

How Often Should Water Hammer Arrestors Be Inspected or Replaced?

Like tuning a finely crafted instrument, you should inspect water hammer arrestors every 1 to 2 years to ensure peak function. Look for leaks, corrosion, or pressure loss.

Replace them if you notice damage or diminished performance, typically every 5 to 7 years depending on system conditions.

Regular maintenance keeps your plumbing system humming smoothly, preventing water hammer from striking harshly and protecting your appliances from shock-induced wear.

Are There Specific Materials Recommended for Arrestor Construction?

You should choose water hammer arrestors made from corrosion-resistant materials like brass or stainless steel to secure durability and compatibility with potable water systems.

The internal components often include stainless steel springs and rubber diaphragms or air chambers designed to withstand pressure fluctuations.

Avoid plastic parts in high-pressure applications. Selecting ASSE 1010 certified arrestors guarantees construction standards meet safety and performance criteria for your plumbing system.

Do Water Hammer Arrestors Affect Water Pressure or Flow Rate?

You won’t notice any significant change in water pressure or flow rate when you install a water hammer arrestor.

These devices gently cushion pressure spikes rather than restricting flow. Their design allows water to pass freely under normal conditions, so your system maintains efficiency.

Proper sizing and placement guarantee minimal hydraulic impact, preserving your plumbing’s performance while minimizing shock effects. Always verify specifications to match system requirements precisely.

Can Water Hammer Arrestors Be Used in Hot Water Lines Safely?

Yes, you can safely use water hammer arrestors on hot water lines.

Make sure the arrestor is rated for the temperature and pressure of your system.

Install it on the hot supply piping near quick-closing valves or fixtures prone to shock.

Proper installation orientation and sizing are important to guarantee effective suppression.

Always follow manufacturer guidelines and test for leaks after installation to maintain system integrity and prevent damage.

Prevent Costly Repairs with Correct Water Hammer Control

By installing water hammer arrestors correctly near pumps, valves, bends, and fixtures, you’ll protect your plumbing system from damage and noise. Did you know that improper placement causes over 60% of water hammer issues?

Make sure you size and pressurize your arrestors precisely and install them vertically or horizontally as needed. Following these steps methodically not only extends your system’s lifespan but also keeps your water flow smooth and silent, saving you costly repairs down the line.