Last Updated on November 25, 2025

If you need to disinfect your well water, consider the Stenner Pump 85MHP17 for precise dosing or the Hayward CL100 for easy, automatic tablet feeding. The Pulsafeeder Chem-Tech Series 100 offers reliable, adjustable flow, while the Peristaltic Dual Head 170JL5 suits smaller setups with quiet operation.

All handle chlorine-resistant materials and adjustable rates to suit your needs. Keep going, and you’ll uncover key tips to choose the best system for your water treatment.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

Stenner Pump Company Stenner Peristaltic...

|

|

|

|

Hayward CL100 Automatic Chlorine Feeder

|

|

|

|

Pulsafeeder X030-XA-AAACXXX Chem-Tech Se...

|

|

|

|

Stenner Pump Company Stenner Peristaltic...

|

|

Key Takeaways

- Stenner Pump 85MHP17 offers adjustable dosing up to 17 GPD with chlorine-resistant Santoprene tubing for reliable well water disinfection.

- Hayward CL100 features a corrosion-proof automatic tablet feeder with easy installation and durable materials for consistent chlorine injection.

- Pulsafeeder Chem-Tech Series 100 provides precise metering up to 30 GPD, chemical-resistant PVC head, and supports pressures up to 100 PSI.

- Peristaltic Dual Head 170JL5 delivers quiet, adjustable flow from 0.5 to 10 GPD with durable Santoprene tubing for smaller-scale applications.

- Choose systems with chlorine-resistant materials, adjustable flow rates, and pressure compatibility up to 100 PSI for effective, long-lasting well water treatment.

Stenner Pump 85mhp17 Peristaltic Chlorine Injection Pump

- Model Number: 85MJH2A2S

- GPD: VARIABLE HIGH PRESSURE 100 PSI speed pump 0.8 to 17 gpd

- Tube and tubing: NUMBER 2 TUBE, SANTOPRENE tube with 20 feet of 1/4 BLACK

If you need precise and adjustable chlorine dosing for your well water system, the Stenner Pump 85MHP17 is an excellent choice. It offers 0.8 to 17.0 gallons per day dosing capacity and handles pressures up to 100 psi, giving you flexibility.

The Santoprene tube resists chlorine corrosion, ensuring durability. You’ll appreciate the complete kit with tubing, check valve, strainer, and mounting bracket for easy installation.

Its adjustable head lets you fine-tune chlorine injection, while the 110/120 Volt power suits standard outlets. Users experience reliable operation and benefit from responsive customer support, making it a trustworthy pump for effective water disinfection.

Best For: Homeowners and water treatment professionals seeking a reliable, adjustable chlorine injection pump for well water systems and other chlorination needs.

Pros:

- Adjustable dosing capacity from 0.8 to 17.0 GPD with pressure handling up to 100 psi for versatile applications.

- Complete installation kit included with tubing, check valve, strainer, and mounting bracket for ease of setup.

- Durable Santoprene tube resists chlorine corrosion, ensuring long-lasting performance.

Cons:

- Limited to standard 110/120 Volt power supply, which may not suit all industrial settings.

Hayward CL100 Automatic Chlorine Feeder

- Uses 3-Inch diameter Tricolor S tablets

- Dial control valve lets you control and adjust the rate of feed

- Easy-Lok threaded cover for safe and convenient access to add tablets

When you need a low-maintenance solution to keep your pool or spa water consistently chlorinated, the Hayward CL100 Automatic Chlorine Feeder stands out with its durable, corrosion-proof design and automatic tablet dispensing.

It works seamlessly with your pump and filter, using 3-inch Tricolor S tablets, and lets you adjust the feed rate with an easy dial. Installation is simple, and the Easy-Lok cover ensures safe, secure tablet loading.

Users praise its reliability, with some lasting over 20 years. Just remember to handle it carefully during maintenance due to the potential harmful gas release.

Best For: Pool and spa owners seeking a low-maintenance, reliable, and easy-to-install automatic chlorine feeder for consistent water chlorination.

Pros:

- Durable, corrosion-proof plastic construction ensures long-lasting use.

- Adjustable feed rate with a convenient dial control for precise chlorination.

- Easy installation with secure Easy-Lok cover and minimal maintenance required.

Cons:

- Potential release of gases during maintenance necessitates safety precautions.

Pulsafeeder Chem-Tech Series 100 Pump, 30 GPD, 100 PSI, 115V

- Chemical-Resistant Materials: Motor and gear shaft are treated with a special lubricant to extend...

- Sealed Gear Train: Lowers maintenance and extends the life of the pump.

- Feed Rate Control: The output is fully adjustable over the entire operating range.

You’ll appreciate the Pulsafeeder Chem-Tech Series 100 Pump if you need a reliable chlorine injection system that delivers precise dosing with minimal maintenance.

It offers a capacity of 30 GPD at 100 PSI, powered by a durable 115V motor with a cool-running diaphragm. The pump’s chemical-resistant PVC head, ceramic ball, and CSPE seats ensure long-lasting performance.

Its sealed gear train and quad ball check system guarantee accurate, dependable metering. You can fully adjust the feed rate across the operating range, while visible check valves make operation verification easy.

This pump is built to last and perform consistently in well water disinfection.

Best For: Professionals and operators seeking a reliable, precise, and low-maintenance chlorine injection pump for well water disinfection and chemical dosing applications.

Pros:

- Durable chemical-resistant materials and cool-running motor ensure long service life.

- Fully adjustable feed rate with visible check valves for easy operation and verification.

- Sealed gear train and quad ball check system provide accurate, dependable metering with reduced maintenance.

Cons:

- Limited to a maximum pressure of 100 PSI, which may not suit higher pressure systems.

Peristaltic Dual Head Adj Rate 170JL5 170GPD 25Psi 1/4W

- Model Number: 45MJH2A1S

- GPD: VARIABLE HIGH PRESSURE 100 PSI speed pump 0.5 to 10 gpd

- Tube and tubing: NUMBER 2 TUBE, SANTOPRENE tube with 20 feet of 1/4 WHITE

The Peristaltic Dual Head Adjustable Rate Pump 170JL5 offers precise control over chlorine dosing, making it ideal for well water systems that demand consistent and reliable disinfection.

With an adjustable output from 0.5 to 10 gallons per day and a 25 PSI rating, it handles sodium hypochlorite efficiently using durable Santoprene tubing. You’ll appreciate its easy installation and quieter operation, plus the improved pump head design that simplifies maintenance.

The kit includes essential fittings and a check valve, ensuring smooth setup. Backed by strong support and stocked in key locations, this pump delivers dependable, long-lasting performance for your water treatment needs.

Best For: homeowners and pool operators seeking a reliable, easy-to-maintain chlorine dosing pump for well water or pool disinfection systems.

Pros:

- Adjustable flow rate from 0.5 to 10 gallons per day allows precise dosing control.

- Durable Santoprene tubing and improved pump head design simplify maintenance and extend service life.

- Includes all necessary fittings and check valve for straightforward installation and reliable operation.

Cons:

- Maximum output of 10 GPD may be insufficient for very large or industrial-scale applications.

Flow Rate & Pressure: Key Factors in Choosing a Chlorine Injection System for Well Water

When choosing a chlorine injection system for your well water, you’ll want to take into account:

Injection Capacity Range

How much chlorine does your well water system need? You should consider the required dosing rate, which usually ranges from 0.5 to 20 gallons per day, to match your water treatment demands.

Make sure the injection system’s capacity surpasses your highest anticipated chlorine use to avoid under-dosing during peak times. Look for pumps with adjustable flow rates so you can fine-tune chlorine injection based on changing water flows.

Also, check if the system handles pressures up to 100 psi if your setup is pressurized. Finally, align the system’s maximum capacity with your well’s flow rate to maintain consistent chlorination without overloading the pump.

Chemical Compatibility Materials

Choosing the right injection capacity is only part of guaranteeing effective chlorination for your well water. You also need to focus on chemical compatibility materials to prevent corrosion and system failure.

Make sure the tubing, seals, and other components are made from chemically resistant materials like Santoprene, PVC, or CSPE, which can withstand sodium hypochlorite’s oxidative nature.

Avoid materials like natural rubber or uncoated metals, as they degrade quickly when exposed to chlorine. Check that fittings, check valves, and diaphragms are rated for both the chemical concentration and pressure in your system.

Selecting components specifically designed for chemical resistance ensures long-term durability and reliable dosing performance, helping your chlorine injection system run smoothly without frequent maintenance or replacement.

Pressure Handling Capability

Since your well water system operates under pressure, you need a chlorine injection system that can handle those levels without leaking or failing.

First, verify the system’s pump pressure rating exceeds your well’s maximum PSI to accommodate head loss and maintain reliable dosing. If your pump generates high pressure, pick a system rated for at least 100 PSI to avoid damage and ensure consistent injection.

Also, match the pump’s pressure capacity with your piping and filter setup to prevent undersized units from struggling. Regularly check your system pressure to keep the injection pump within its rated range, avoiding over-pressurization that could compromise performance.

Power Supply Requirements

Although chlorine injection systems vary in design, ensuring their power supply matches your available electrical setup is essential for reliable operation.

Most residential systems run on standard 110/120 Volt outlets, so confirm compatibility before purchasing. You’ll also want to check if the system requires AC power or supports DC or battery options, especially if your site lacks stable mains electricity.

Be mindful of power consumption to avoid overloading breakers or increasing energy bills. Verify whether the system includes built-in adapters or if you’ll need external transformers for proper voltage regulation.

Finally, prioritize safety features like grounding and waterproof enclosures to prevent electrical hazards. Taking these power supply factors into account will help you select a chlorine injection system that runs efficiently and safely in your well water setup.

Installation and Maintenance

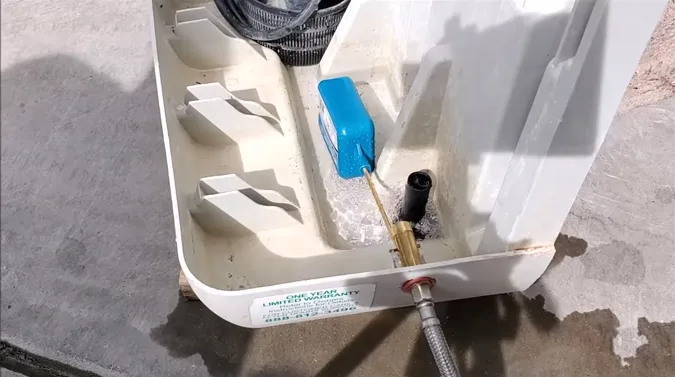

When installing a chlorine injection system, you need to guarantee all connections are secure and reinforced to prevent damage during shipping and operation. Use Teflon tape generously on threaded fittings to ensure leak-proof joints throughout the system.

Regularly inspect and clean the injection check valves and tubing to maintain consistent chlorine dosing and avoid clogs. Adjust the pump’s head and pressure settings carefully to match your well water volume and achieve the desired chlorine flow rate.

Incorporate flow indicators or sight tubes so you can monitor the system’s operation and quickly spot any issues with chemical injection. Proper installation and routine maintenance not only ensure reliable disinfection but also extend the lifespan of your chlorine injection system.

Dosing Accuracy Control

To guarantee your well water remains safe and properly treated, you need a chlorine injection system that offers precise dosing control. Accurate dosing prevents over- or under-chlorination, maintaining consistent residual chlorine levels essential for water safety.

Look for systems with adjustable flow rates and head settings so you can fine-tune chlorine output based on your specific water treatment needs. Incorporating flow meters or sensors lets the system monitor real-time flow and automatically adjust injection, ensuring ideal dosing accuracy.

Reliable check valves and sealed tubing are vital to prevent backflow and leaks, keeping chlorine delivery consistent. Don’t forget regular calibration and maintenance—they’re key to sustaining dosing accuracy over time and avoiding fluctuations in chlorine levels that could compromise water quality.

Included Accessories Kit

A well-equipped accessories kit plays an essential role in setting up your chlorine injection system for well water. It usually includes connecting nuts, ferrules, tubing, check valves, strainers, and mounting brackets, all crucial for a smooth installation.

The tubing’s length and diameter must match your pump and application, ensuring proper flow. Check valves prevent backflow, protecting your water from contamination and maintaining consistent dosing.

Strainers keep debris out, while mounting brackets secure the system in place, making maintenance easier. Choosing a system with a comprehensive accessories kit saves you from hunting down extra parts and simplifies setup.

Frequently Asked Questions

How Often Should Chlorine Injection Systems Be Serviced?

You should service your chlorine injection system at least once every six months to guarantee it’s working properly. Regular maintenance helps prevent clogs, checks for leaks, and ensures the dosing pump operates efficiently.

If you notice any irregular chlorine levels or strange odors, you might need to service it more often. Always follow the manufacturer’s guidelines, and don’t forget to replace worn parts promptly to keep your water safe and clean.

Can Chlorine Injection Systems Handle Varying Well Water Flow Rates?

Oh sure, chlorine injection systems are just thrilled to babysit your unpredictable well water flow rates! In reality, many systems are designed to handle varying flow rates by adjusting injection rates accordingly.

You’ll want a model with a flow sensor or adjustable settings so it can keep disinfection consistent. Otherwise, you might end up with either a chlorine overdose or a weak defense, neither of which your water wants to drink!

Are There Any Safety Precautions When Handling Chlorine for Injection?

You should always wear protective gear like gloves and goggles when handling chlorine to avoid skin and eye irritation. Make sure the area is well-ventilated to prevent inhaling harmful fumes.

Never mix chlorine with other chemicals, especially ammonia, as it can create toxic gases. Store chlorine in a cool, dry place away from direct sunlight and keep it out of reach of children.

How Does Chlorine Injection Affect the Taste and Odor of Water?

Imagine you notice a slight chemical taste after installing a chlorine injection system. Chlorine can change your water’s taste and odor by adding a mild bleach-like flavor, especially if levels are high.

You might find it unpleasant at first, but it usually fades as chlorine dissipates. To keep your water tasting better, you can adjust chlorine levels or use activated carbon filters to reduce that taste and smell.

What Are the Environmental Impacts of Chlorine Injection in Well Water?

When you use chlorine injection in well water, you need to consider potential environmental impacts. Chlorine can form harmful byproducts that affect aquatic life if discharged into nearby water bodies.

Overuse may disrupt local ecosystems and harm beneficial bacteria in soil and water. You should ensure proper dosing and treatment to minimize these risks, and always follow local regulations to protect the environment while keeping your water safe.

Simplify Clean Water with the Right Chlorine Injection System

Choosing the right chlorine injection system for your well water doesn’t have to be an intimidating chore. With options like the Stenner Pump or the Hayward CL100, you’re set to gently usher in cleaner, safer water without the hassle.

Keep in mind the flow rate and pressure to find your perfect match. By making a thoughtful choice, you’re not just disinfecting you’re embracing a smoother, fresher water experience for your home.

Last update on 2026-02-24 / Affiliate links / Images from Amazon Product Advertising API