Last Updated on May 25, 2025

You’ll face pipe bursts in summer mainly because high temperatures cause thermal expansion and material stress, while soil drying shifts underground pipes.

Increased water demand raises pressure, straining aging or corroded infrastructure. Tree roots also invade cracks, worsening leaks. Clogs elevate pressure behind blockages, risking ruptures.

Regular inspections and pressure management help prevent damage. Understanding these factors lets you take targeted action to protect your pipes and avoid costly repairs when temperatures rise.

Key Takeaways

- High temperatures cause thermal expansion and increased pressure, stressing pipes and causing cracks or bursts.

- Dry soil shifts and ground settlement during summer increase stress on underground pipes, leading to damage.

- Increased water demand raises internal pipeline pressure, risking leaks or ruptures in aging or weak pipes.

- Tree roots seek moisture in dry conditions, penetrating small cracks and causing blockages or pipe damage.

- Clogs create pressure buildup behind blockages, combined with thermal expansion, increasing the likelihood of pipe bursts.

Effects of High Temperatures on Pipes

When high temperatures hit, your pipes don’t just sit idle—they expand, which can create significant stress on the system if not properly accounted for. This thermal expansion increases pressure on fittings and connections, raising the risk of leaks or bursts.

You need to use materials with low thermal expansion coefficients or composite materials designed for heat resistance to reduce damage. Older pipes are especially vulnerable since existing wear worsens thermal stress effects.

To manage expansion, incorporating expansion joints or looped pipe designs is essential. Without these measures, pipes can buckle or fracture under pressure.

Additionally, extreme heat accelerates corrosion in metal pipes and causes plastic pipes to become brittle, both of which increase the likelihood of failure.

The extreme heat also causes the ground to dry out, which can lead roots to seek moisture and potentially disturb underground pipes. Regular inspection and maintenance during hot months help you catch these issues early.

Impact of Soil Conditions During Summer

Although soil is often overlooked, its condition during summer plays a crucial role in pipe integrity. When soil dries out, it shifts and contracts, especially in clay-heavy areas, increasing stress on underground pipes.

This stress can cause cracks or bursts, particularly in older or corroded pipes. You should consider these key factors:

- Soil drying causes shifting and ground settlement, destabilizing pipes.

- Clay soils contract considerably, elevating pipe movement risks.

- Soil erosion from dry spells can expose and weaken pipe foundations.

- Nearby construction or seismic activity intensifies soil shifts impacting pipes.

- Incorporating flexible joints helps pipes adjust to these ground shifts, reducing the risk of damage.

Understanding and monitoring these soil conditions can help you prevent costly pipe failures during summer months.

Increased Water Demand and Pressure

During summer peak usage times, your plumbing system experiences higher stress due to simultaneous water demand. This surge in pressure can expose weaknesses, leading to pipe failures or bursts.

Understanding these pressure-induced effects is essential to prevent costly damage. High water demands can exacerbate existing issues in older plumbing systems.

Peak Usage Effects

Because summer drives a surge in outdoor water use, municipal systems face significant increases in demand and pressure. You’ll notice peak usage periods strain water delivery infrastructure due to heightened flow volumes and variable hydraulic conditions.

This seasonal surge impacts pipe integrity in several ways:

- Water demand can nearly triple from winter lows, intensifying system load.

- Flow rate fluctuations during peak use alter velocity and stress distribution inside pipes.

- Municipal providers must ramp up production, pushing system components closer to operational limits.

- Increased wear from sustained high usage accelerates material fatigue and failure risks.

Understanding these peak usage effects helps you appreciate how summer water consumption patterns contribute to pipe vulnerabilities beyond just pressure concerns.

Efficient water use goals recommend limiting outdoor water to 12 gallons per square foot per year to reduce such strain. Managing demand spikes is critical to maintaining infrastructure reliability throughout hot months.

Pressure-Induced Failures

The surge in water demand throughout summer not only stresses the municipal supply but also raises internal pipeline pressures that can lead to failures.

When you increase water use for irrigation or pool filling, pressure inside pipes builds up, risking leaks or ruptures, especially in aging or improperly installed systems. High pressure strains pipe materials, accelerating wear and potential failure.

Climate conditions, such as seasonal temperature changes, also contribute to increased failure rates in pipes during the summer months due to thermal stresses and pipe-soil interactions seasonal temperature changes.

You can mitigate these risks by installing pressure relief valves and regulators to maintain safe pressure levels. Regular maintenance and system monitoring help detect pressure anomalies early, preventing catastrophic bursts.

Also, consider pipe materials resistant to pressure fluctuations. Remember, soil conditions and tree root intrusion can exacerbate pressure problems, so addressing these factors is critical. Managing pressure effectively reduces summer pipe failure and extends infrastructure lifespan.

Role of Aging Infrastructure in Pipe Bursts

While many factors contribute to pipe bursts in summer, aging infrastructure plays a critical role you can’t ignore. About 33% of water mains in the U.S. and Canada are over 50 years old, with an average failure age of 53 years.

These older pipes, often made from cast iron or asbestos cement, have higher break rates. One-third of U.S. and Canadian water mains are over 50 years old, prone to higher break rates.

Here’s what you should know:

- Aging pipes cause roughly 260,000 breaks annually, costing $2.6 billion in repairs.

- Older materials break more frequently despite overall break rates dropping due to modern replacements.

- PVC and ductile iron pipes offer better durability and lower failure rates.

- Effective asset management and condition assessments are essential to reduce risks and costs from aging pipes.

The inability to replace aging water mains timely is often due to inadequate funding, exacerbating the risk of pipe bursts. Addressing aging infrastructure is key to preventing summer pipe bursts.

Influence of Tree Roots on Pipe Integrity

You’ll notice that tree roots accelerate their growth in summer, increasing the risk of penetrating vulnerable pipes through cracks or loose joints. This intrusion can severely compromise pipe integrity, leading to blockages and structural damage.

Roots block flow of waste, causing toilet paper and solids to catch inside pipes. Implementing targeted root control methods, like chemical treatments or mechanical removal, helps protect your system and maintain flow capacity.

Root Growth Acceleration

Because tree roots aggressively seek moisture during summer, they accelerate growth toward underground pipes, increasing the risk of structural damage. You should understand that this rapid root expansion can exert pressure, penetrate cracks, and block pipe interiors.

To manage these risks effectively, consider these key factors:

- Tree species with aggressive roots grow faster and pose greater threats.

- Loose or sandy soil allows easier root penetration and expansion.

- Drought conditions intensify root growth toward water sources, including your pipes.

- Older or damaged pipes are more vulnerable to intrusion and failure.

Additionally, small cracks or joints in pipes can leak wastewater, which tree roots detect and grow into, causing further infiltration and damage pipe leakage.

Pipe Penetration Risks

If tree roots find cracks, joints, or damaged seals in your pipes, they’ll quickly invade these weak points rather than breaking through solid pipe walls.

Older pipes made of cement or rubber-sealed materials degrade over time, increasing vulnerability. Once inside, roots obstruct flow, causing backups and overflows, while exerting pressure that cracks or displaces pipes.

These blockages reduce hydraulic capacity and may lead to soil contamination through pipe exfiltration. Moisture and oxygen leaks near pipes attract roots, especially during summer growth spurts.

Large trees with extensive root systems pose greater risks by applying mechanical force. Understand that tree roots typically grow only a few feet deep but can extend far beyond the canopy, which means their reach underground is often underestimated root depth.

Properly installed PVC pipes lower intrusion chances due to enhanced joint integrity. Regular inspections to repair damage and strategic tree placement help maintain pipe integrity and reduce costly root-related failures.

Root Control Methods

Effective root control methods are essential to preserving pipe integrity and preventing costly damage. Tree roots exploit existing cracks and deteriorated seals, particularly in older pipes, to invade and obstruct flow.

To protect your pipes, consider these key strategies:

- Use root-resistant materials like PVC to minimize penetration risks.

- Schedule regular inspections and maintenance to catch early root intrusion.

- Install physical barriers, such as root guards, around vulnerable joints.

- Apply chemical root inhibitors periodically to prevent root growth inside pipes. It is important to remember that roots only enter pipes through existing openings, which indicates that prior damage must be addressed to prevent intrusion.

Additionally, plan tree planting carefully by choosing less aggressive species and positioning them away from pipelines. Implementing these measures reduces blockages, structural damage, and costly repairs, especially during dry summer months when roots aggressively seek water.

Common Types of Pipe Damage in Hot Weather

Five common types of pipe damage tend to occur in hot weather, each driven by distinct stressors that compromise pipe integrity.

You’ll encounter thermal expansion causing stress and fractures, soil shifting that displaces pipes underground, and tree root intrusion breaking pipe walls. Increased water pressure from summer use raises the risk of leaks, while corrosion accelerates material degradation.

Additionally, tree roots grow faster during summer, which can exacerbate root intrusion issues and cause more severe damage to pipes.

| Damage Type | Cause | Effect |

|---|---|---|

| Thermal Expansion | Heat stress on materials | Cracks, buckling |

| Soil Shifting | Dry soil contraction | Pipe displacement |

| Root Intrusion | Roots seeking water | Blockages, fractures |

Relationship Between Clogging and Pipe Bursts

Beyond the physical damage caused by heat and soil shifting, clogs play a significant role in causing pipe bursts during summer. When debris blocks water flow, pressure builds behind the clog, stressing pipe walls and joints.

Warm summer temperatures worsen this by expanding water volume, increasing internal pressure. Additionally, mineral deposits from hard water can accumulate, narrowing pipes and exacerbating clog-related pressure.

You can prevent bursts by understanding these key points:

- Blocked flow causes water backup, increasing pressure inside pipes.

- Frequent or severe clogs fatigue pipes, making them prone to failure.

- Overstressed joints leak or rupture under sustained high pressure.

- Hidden clogs create pressure surges that weaken the entire system.

Recognizing and addressing clogs early helps maintain pipe integrity and prevents costly burst incidents during hot months.

Importance of Regular Pipe Inspections

You need to spot early pipe damage before it leads to costly bursts, especially during summer heat. Regular inspections support preventive maintenance by identifying expansion and stress points that compromise pipe integrity.

They also allow for targeted risk analysis, focusing on sections with the highest probability of failure. Staying ahead of these issues minimizes repair costs and extends your system’s lifespan.

Detecting Early Pipe Damage

Detecting early pipe damage hinges on consistent inspections and awareness. You’ll want to monitor for visual and auditory signs that reveal developing issues.

- Visual Checks: Inspect exposed pipes for corrosion, moisture, or warping in floors, walls, and ceilings.

- Auditory Monitoring: Listen for hissing or dripping sounds when faucets are off; these indicate leaks.

- Water Usage Analysis: Track water bills and meter readings for unexplained spikes or continuous flow. An unexpected increase in your water bill can be an early sign of a hidden leak.

- Use Detection Tools: Employ moisture meters, infrared cameras, or smart sensors to identify hidden leaks. Advanced tools like infrared thermal imaging can pinpoint leaks without damaging your walls or floors.

Preventive Maintenance Benefits

Although it may seem routine, regular pipe inspections play an essential role in extending the lifespan of your piping system. By identifying corrosion, blockages, or areas needing cleaning early, you prevent costly damage and reduce replacement frequency.

Inspections enable you to focus resources on high-risk sections, enhancing maintenance efforts and lowering long-term costs. Using video assessments, you gain real-time insights that improve operational efficiency by maintaining peak flow rates and reducing energy consumption.

Proactive detection of potential failures minimizes downtime and emergency repairs, saving you significant expenses. Regular maintenance also reduces environmental impact by preventing leaks and spills, which is critical during high usage seasons like summer.

Additionally, routine inspections help guarantee compliance with safety standards, protect community health, and prevent environmental hazards. Incorporating regular inspections into your maintenance plan is a practical strategy to safeguard your pipes and maintain reliable system performance.

Identifying Expansion and Stress

Because pipes undergo continuous expansion and contraction during summer, regular inspections become essential for identifying stress-related issues before they escalate.

You’ll need to look for signs of thermal expansion effects like warping or buckling, especially in metal and PVC pipes. Check for pressure-related fatigue caused by increased water demand and fluctuating supply.

Thermal expansion causes materials to expand when heated, increasing the risk of damage in confined plumbing spaces. Aging pipes require particular attention for corrosion, thinning walls, or brittleness.

Also, monitor ground movement for misalignments or stress points that can worsen pipe integrity.

- Detect material deformation or micro-fractures from thermal cycling.

- Identify pressure surges stressing joints and pipe walls.

- Assess aging-related vulnerabilities and previous repairs.

- Observe environmental shifts affecting pipe alignment.

Regular inspections help you catch early damage and prevent costly bursts.

Preventative Measures to Avoid Summer Pipe Bursts

To prevent summer pipe bursts, you need to implement targeted measures that address heat, pressure, and environmental stressors.

Start with regular inspections and pipe condition assessments to catch early signs of wear or corrosion. Use heat-resistant materials and protect exposed pipes with foam insulation or light-colored coatings.

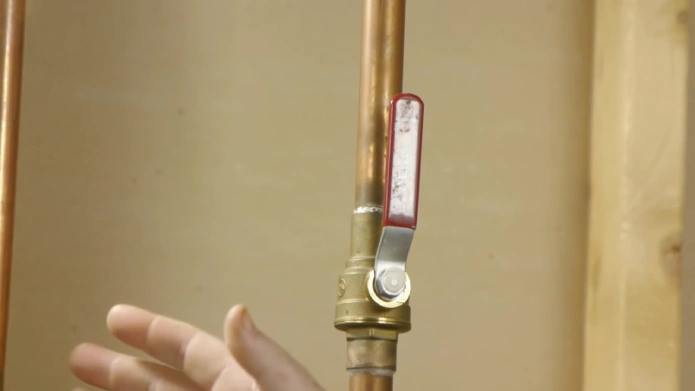

Manage thermal expansion and pressure fluctuations by installing expansion tanks and pressure relief valves. Monitor water pressure and avoid simultaneous heavy water use to reduce stress on pipes.

Address soil movement by stabilizing ground and ensuring proper drainage. Additionally, professional maintenance can help identify vulnerabilities before they lead to pipe failure.

| Inspection & Maintenance | Pressure Management |

|---|---|

| Regular inspections | Pressure relief valves |

| Corrosion monitoring | Expansion tanks |

| Pressure-reducing valves | |

| Insulation & Protection | Environmental Control |

| Foam insulation | Ground stabilization |

| Pipe coatings | Drainage improvement |

Frequently Asked Questions

Can Certain Pipe Materials Handle Summer Heat Better Than Others?

Yes, certain pipe materials handle summer heat better than others. You’ll find CPVC, PB, and PVDF pipes excel due to their higher long-term heat resistance—up to 95°C or more—making them less prone to cracking or bursting.

Steel pipes also resist thermal expansion and maintain strength under heat. In contrast, PVC-U pipes tolerate lower temperatures and risk damage. Choosing materials with suitable heat and chemical resistance helps you avoid heat-induced failures efficiently.

How Does Summer Pipe Bursting Risk Compare to Winter Pipe Bursts?

You’ll find winter pipe bursts occur more frequently due to freezing water expanding inside pipes, causing ruptures. In contrast, summer pipe bursts happen less often but result from thermal expansion, soil shifting, and increased water pressure.

While winter demands insulation against freezing, summer requires monitoring soil conditions and managing pressure. Both seasons stress pipes differently, so you should adapt your prevention strategies accordingly to minimize risks year-round.

Are Underground Pipes More Vulnerable to Summer Bursts Than Indoor Pipes?

You might think underground pipes are tough, buried deep and all, but ironically, they’re more vulnerable to summer bursts than indoor pipes.

That’s because soil shifts, tree roots, and moisture changes wreak havoc underground, causing cracks or disconnections. Indoor pipes enjoy stable temperatures and easier maintenance, so they handle summer stress better.

Does Water Hardness Affect Pipe Bursting During Summer Months?

Yes, water hardness directly affects pipe bursting in summer. You’ll find that mineral buildup from hard water narrows pipes, increasing internal pressure. Combined with summer heat, this accelerates corrosion and weakens pipe walls.

As minerals concentrate further due to evaporation, scale buildup intensifies, raising burst risk. To protect your pipes, you should use water softeners and perform regular maintenance to minimize mineral deposits and stress on your plumbing system.

Can DIY Pipe Insulation Help Prevent Summer Pipe Bursts?

DIY pipe insulation won’t directly prevent summer pipe bursts since bursts mainly result from pressure spikes and material degradation, not temperature loss.

However, insulating your pipes helps maintain consistent water temperature and reduces thermal stress, indirectly lowering risk. It also cuts energy use and prevents condensation, which may cause corrosion.

Prevent Costly Repairs with a Proactive Approach

When summer heat hits, your pipes face multiple risks—from soil shifts and increased pressure to aging infrastructure and invasive roots. Remember, “an ounce of prevention is worth a pound of cure.”

Regular inspections and timely maintenance can save you costly repairs and service disruptions.

Stay proactive in monitoring your pipes, address clogs promptly, and implement preventative measures to keep your plumbing system resilient throughout the hot months.