Last Updated on April 20, 2025

SuperPEX pipes are designed for efficient hot and cold potable water distribution, offering superior chlorine and UV resistance compared to other PEX varieties.

With a durable cross-linked polyethylene construction, they reduce surge pressures and guarantee consistent water quality. Their flexible design simplifies installation, saving you time and labor costs.

Regular maintenance, including sediment flushing and chlorination, helps extend their lifespan. If you’re interested in their specific features and advantages, you’ll find more informative details ahead.

- For hot water distribution

- High chlorine resistance

- Exclusive inner layer

Key Takeaways

- SuperPEX pipes are engineered from cross-linked polyethylene, ensuring efficient hot and cold water distribution with superior chlorine and UV resistance.

- The flexible design allows for easier installation around corners, reducing the need for fittings and minimizing leak points.

- With a lifespan exceeding 50 years, SuperPEX offers cost-effective durability and requires minimal maintenance, including routine inspections and occasional chlorination.

- Compliance with stringent ASTM and NSF standards guarantees high performance and safety for residential and commercial applications.

- Unlike competitors, SuperPEX features a multi-layer design and offers color coding for easy identification, enhancing overall reliability.

Overview of SuperPEX Pipes

SuperPEX pipes are engineered for efficient distribution of hot and cold potable water across various applications, including residential, commercial, and industrial settings.

They comply with stringent manufacturing standards such as ASTM F 876 and ANSI/NSF 61, ensuring safety and quality in potable water systems.

When installing, you’ll need to adhere to guidelines that prevent exposure to direct sunlight and maintain at least 18 inches from gas appliances to avoid heat damage.

SuperPEX also accommodates thermal expansion, expanding at a rate of approximately 7.9 x 10^-5 in/in°F, necessitating slack for movement.

Its compatibility with other materials, like copper and CPVC, allows for versatile connections, provided you use approved fittings, ensuring a leak-free system.

Additionally, SuperPEX pipes utilize advanced technology in cross-linked polyethylene to enhance their durability and performance.

Physical Properties and Specifications

When selecting PEX pipes for your plumbing needs, understanding their physical properties and specifications is essential.

PEX pipes consist of cross-linked polyethylene (HDPE), created through peroxide, silane, or electron beam methods, with a crosslink density between 65% and 89% per ASTM F876.

This crosslinking enhances their chemical resistance and structural integrity. The density is around 938 kg/m³, with tensile strength ranging from 20 to 26 N/mm² at 20°C and 9 to 13 N/mm² at 100°C. PEX also exhibits flexibility, with significant elongation at break.

Designed for both hot and cold water systems, it withstands high temperatures and freezing conditions. Available in diameters from three-eighths to 2 inches, PEX pipes meet ASTM standards for residential applications.

Additionally, PEX is known for its durability and can last at least 50 years with proper maintenance.

Installation Advantages

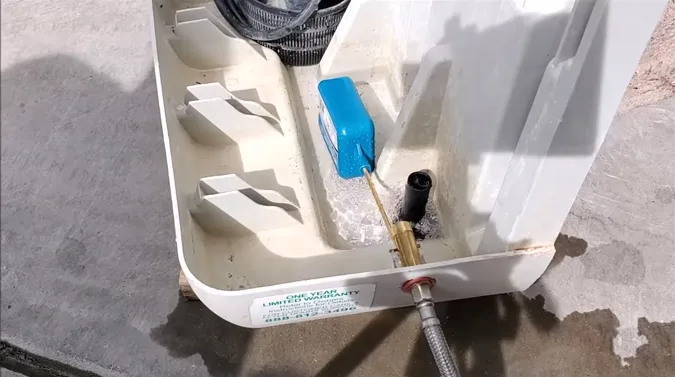

When you install Superpex pipes, you’ll appreciate their flexible design, allowing you to navigate corners and obstacles with fewer fittings. This flexibility, combined with simplified connection methods like push-fit and crimp connections, streamlines the installation process considerably.

As a result, you can save time and reduce labor costs while ensuring secure connections throughout your plumbing system. Additionally, the non-corrosive properties of PEX ensure that your water quality remains consistent over time.

Flexible Design Benefits

One of the standout features of PEX pipes is their remarkable flexibility, which greatly enhances installation efficiency.

This flexibility allows you to bend PEX around corners without needing additional connectors or elbows, considerably reducing potential leak points. You can install PEX in long, continuous sections, minimizing joints and further lowering leak risks.

The design simplifies installation in tight or complex spaces, saving you time and labor costs. With fewer fittings required, your overall project expenses decrease, and PEX’s adaptability makes it suitable for various environments without extensive modifications.

Additionally, PEX’s long lifespan ensures that you benefit from a durable plumbing solution that requires minimal maintenance over the years. Notably, PEX is more resistant to freezing conditions, making it an ideal choice for colder climates.

This streamlined process not only boosts efficiency but also guarantees that your plumbing system performs effectively, enhancing water flow and reducing pressure losses.

Simplified Connection Methods

Numerous connection methods available for PEX pipes simplify the installation process, making it accessible even for those with limited plumbing experience. Crimp connections use copper rings and a crimping tool, ensuring durability and high-pressure resistance.

Additionally, crimped connections are widely used for their reliability in various plumbing applications. Alternatively, push-fit connections allow for quick, tool-free installation, perfect for rapid projects.

If you’re working with PEX-a pipes, expansion connections provide versatility with a specialized tool to manage the fitting’s expansion. For high-temperature applications, metallic fittings are recommended, while EvoPEX fittings offer a visual indicator to confirm secure connections.

Furthermore, PEX is resistant to cracking from freezing, which enhances its reliability in various installation scenarios. Each method presents unique advantages, allowing you to choose the best fit for your specific needs, enhancing both speed and efficiency during installation.

Applications and Use Cases

No products found.

SuperPEX pipes are increasingly utilized in both residential and commercial water systems due to their exceptional flexibility and resistance to corrosion. Their ability to handle varying water pressures and temperatures makes them ideal for diverse installation scenarios.

Additionally, the smooth interior of SuperPEX pipes guarantees efficient water flow, minimizing the risk of contamination and scaling. Furthermore, their long lifespan reduces the need for frequent replacements, making them a cost-effective choice for both homeowners and businesses.

Residential Water Systems

When considering options for residential water systems, the versatility of SuperPEX becomes evident in various applications. This PEX-b piping is suitable for both hot and cold potable water distribution, showcasing flexibility that simplifies installation.

Available in multiple sizes and configurations, you can easily adapt SuperPEX for renovation projects or new builds, including multi-family and high-rise structures. During installation, verify pipes remain at least 12″ vertically or 6″ horizontally from high heat sources, while connections must be above concrete slabs.

SuperPEX’s resistance to UV degradation and corrosion makes it a reliable choice for domestic water supply systems, meeting stringent plumbing codes across the U.S. and Canada, ultimately providing a durable and cost-effective solution for residential plumbing.

Moreover, its triple layer tubing design offers the highest protection against UV rays per ASTM standards, enhancing its suitability for various environments. Additionally, ensuring proper insulation and weatherization of the surrounding areas can further improve the overall efficiency of the plumbing system.

Commercial Installation Applications

In commercial settings, the adaptability of SuperPEX piping proves advantageous across various installation applications.

For public fixtures and restrooms, its PEX-a material considerably reduces surge pressures and absorbs noise, making it ideal for high-traffic areas. This is particularly important as PEX-a reduces surge pressures by 18-40% compared to metallic piping.

When installed in fire-resistant constructions, SuperPEX meets ASTM E119 standards, ensuring compliance and safety.

In plenum installations, it facilitates air circulation and adheres to ASTM E84 requirements.

Its flexible nature allows for easy configurations in commercial and industrial water distribution systems, available in multiple sizes.

SuperPEX also excels in specialized systems like geothermal and radiant cooling applications, where its smooth interior enhances fluid flow.

This versatility makes SuperPEX a reliable choice for diverse commercial needs.

Comparison With Other PEX Products

Though various PEX products are available on the market, comparing SuperPEX with its counterparts—PEX-A, PEX-B, and PEX-C—highlights its unique advantages and specifications.

| Feature | SuperPEX |

|---|---|

| Chlorine Resistance | Highest |

| UV Resistance | 180 days |

| Multi-Layer Design | Yes |

| Color Coding | Red, White, Blue |

| Compatibility | Crimp and push-to-connect |

While PEX-A excels in flexibility, SuperPEX’s superior chlorine and UV resistance make it ideal for demanding environments. Notably, all PEX pipes must meet ASTM F876 and NSF/ANSI/CAN 61 performance standards, ensuring that SuperPEX maintains high reliability in various applications.

PEX-B offers size variability but lacks the multi-layer protection of SuperPEX. PEX-C is limited to specific applications, whereas SuperPEX guarantees versatility across various projects. Ultimately, SuperPEX stands out for its robust performance and reliability.

Durability and Maintenance Considerations

While considering the longevity of your plumbing system, it’s vital to understand the durability and maintenance requirements of SuperPEX pipes.

These pipes resist corrosion, ensuring a long lifespan, but you should avoid excessive heat sources to maintain their flexibility. Proper insulation prevents freeze damage, which can severely affect PEX integrity. Proactive PEX maintenance is essential in extending the system’s lifespan beyond 50 years.

Regular visual inspections for leaks and damage are essential, along with sediment flushing every three years. Chlorination every five years helps prevent bacterial growth.

Frequently Asked Questions

How Does Superpex Handle Expansions Due to Temperature Changes?

Superpex pipes handle expansions due to temperature changes by utilizing their high thermal expansion coefficient, which can lead to significant length increases.

To accommodate this, you’ll need to implement expansion loops or offsets in your installation design. Proper management prevents stress on fittings and joints, minimizing leak risks.

Additionally, guarantee your system can handle temperature variations by regularly inspecting the pipes, so they maintain their integrity and performance over time.

Can Superpex Pipes Be Used for Gas Distribution Systems?

No, you can’t use Superpex pipes for gas distribution systems.

They’re designed primarily for water distribution and comply with drinking water standards.

For gas applications, consider using PEX-AL-PEX pipes instead, as they offer better durability and pressure resistance.

Make certain you follow the installation guidelines and safety codes specific to gas systems to prevent issues.

Always opt for fittings approved by the manufacturer for peak performance and safety in gas distribution.

What Certifications Do Superpex Pipes Hold?

SuperPEX pipes typically hold several important certifications, ensuring their safety and compliance.

You’ll find that they meet NSF/ANSI/CAN 61 standards for health effects, and they’re labeled with the NSF Validation Mark for traceability.

Additionally, they comply with lead-free requirements as per U.S. laws.

The manufacturer’s name and conformance information are also included on the product labels, indicating adherence to relevant standards and codes for potable water systems and other applications.

Are Superpex Pipes Recyclable After Their Lifespan?

PEX pipes, including Superpex, present recycling challenges due to their cross-linked structure, which complicates conventional melting processes.

While you can’t typically recycle them like copper, advancements in chemical recycling, such as pyrolysis, enable the breakdown of PEX into raw materials for new pipes.

Currently, most PEX waste is repurposed or incinerated; however, ongoing innovations aim to enhance recyclability, paving the way for more sustainable practices in the future.

How Do I Clean Superpex Pipes if Needed?

When your pipes need a little TLC, start with a pre-cleaning assessment to identify blockages.

Choose between mechanical cleaning with a pipe snake, chemical solutions designed for PEX, or hydro-jetting for tough debris. Make certain you’ve got protective gear on.

Once you apply the cleaning solution, circulate for about 30 minutes, then drain and rinse thoroughly.

Finally, double-check that everything flows smoothly before considering the job done. Regular maintenance keeps problems at bay!

SuperPEX: The Smart Choice for Seamless Installations

To summarize, SuperPEX pipes stand out as a reliable choice for plumbing and heating needs. With their impressive physical properties and ease of installation, they make your projects smoother than a well-oiled machine.

Their versatility in various applications guarantees you’re covered, whether for residential or commercial use.

By choosing SuperPEX, you’re investing in durability and low maintenance, making them a smart long-term solution for any piping system. Don’t overlook the benefits they bring to your next endeavor.

- For cold water distribution

- High chlorine resistance

- Exclusive inner layer

Last update on 2026-02-06 / Affiliate links / Images from Amazon Product Advertising API