Yes, you can transport a water heater on its side, but you must take specific precautions to prevent internal damage like cracking the glass lining or bending key components.

Always pad the heater, position the control panel side up or opposite, and secure it to avoid movement. After transport, let it settle upright for several hours and flush the tank before use.

If you want to handle it safely, understanding the proper handling and post-transport steps is essential.

Key Takeaways

- Transporting a water heater on its side risks damaging the internal glass lining and components, leading to corrosion and leaks.

- It may be necessary to lay a heater on its side in tight spaces or narrow doorways during moving or installation.

- Always wrap the heater with padding and position it control panel side down to minimize damage when laying it on its side.

- After side transport, drain, flush, and allow the heater to stand upright for several hours before use to prevent issues.

- Properly secure and protect the heater during transport to avoid dents, shifting.

Risks Associated With Transporting a Water Heater on Its Side

When you transport a water heater on its side, you risk cracking the internal glass lining that protects the tank from corrosion. This lining prevents rust, but uneven weight distribution during side transport can chip or fracture it. This damage can lead to premature tank failure and costly repairs.

Once damaged, the tank becomes vulnerable to rust, shortening its lifespan and causing long-term failures. Additionally, laying the heater sideways exposes it to dents and scratches, compromising structural integrity and increasing leak risks.

Damage leads to rust, reduced lifespan, and leaks from compromised structural integrity when a water heater is laid sideways.

Internal components like copper tubes and anode rods may shift or sustain damage from movement and vibration, impairing performance. These issues often go unnoticed initially but cause faults later. Proper precautions can reduce the risk of internal component misalignment.

Situations That May Require Side Transport

Although transporting a water heater upright is ideal, certain scenarios force you to lay it on its side. Space constraints such as narrow doorways, tight hallways, or limited vehicle cargo height often prevent vertical movement.

Older buildings with confined entry points or limited vertical clearance inside trucks or SUVs necessitate horizontal positioning. When moving multiple units, side transport optimizes space in flatbeds or trailers.

During installation, you might briefly lay the heater on its side to navigate tight spots, use dollies designed for tilted movement, or accommodate limited lifting equipment height. Emergency situations like last-minute replacements, vehicle changes, or obstructed access also require side transport.

Additionally, specific models with reinforced structures or manufacturer guidelines may permit horizontal transport, making side loading a practical option in select cases.

However, understand that transporting a water heater on its side can cause internal component damage, potentially affecting performance and longevity.

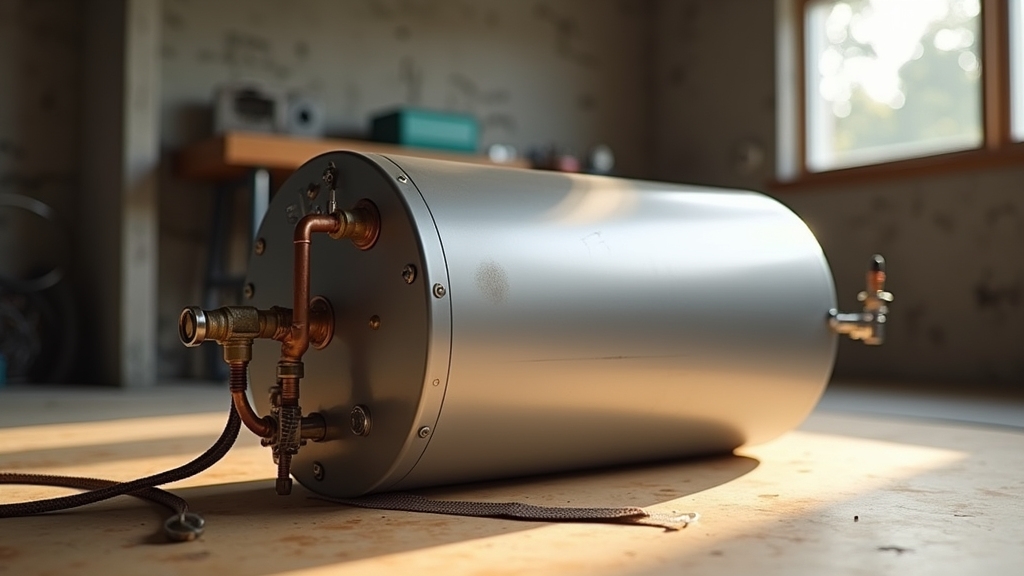

Precautions to Take When Laying a Water Heater Down

To prevent damage while laying a water heater on its side, you must secure ample cushioning and protection around the unit. Wrap the heater with blankets, towels, or foam padding, focusing on the side that will contact the ground to avoid scratches or dents.

Proper padding also helps reduce the risk of leaks that can occur from impacts during transport. Additionally, understanding the internal components can help you avoid accidental damage during handling, such as by being aware of the location of the mechanical seal.

Position the heater opposite the control panel side down to safeguard sensitive components. Place it on a flat, stable surface and use supports or blocks to prevent rolling or shifting. Secure with straps or bungee cords to minimize movement.

Avoid stacking items on top to prevent pressure damage. Keep away from heavy or sharp objects that could puncture the tank. Ensure the transport environment is dry and temperature-controlled to prevent corrosion or freezing.

Steps to Follow After Transporting on Its Side

Since transporting a water heater on its side can disrupt internal components and loosen sediment, you should immediately drain and flush the tank before refilling. Drain all water to prevent operational damage, then flush thoroughly to remove loosened sediment.

Inspect the drain valve for leaks or blockages. Additionally, ensure that any safety devices such as pressure/temperature relief valves are inspected and functioning properly to comply with safety regulations. It is also important to check for any signs of water leaks that might have developed during transport.

Afterward, keep the tank upright and allow it to settle for 4 to 24 hours to let oils, anode rods, and internal parts resettle, following manufacturer guidelines. Examine the exterior, fittings, and internal components for damage or displacement.

Once settled, reopen the water supply slowly, monitor pressure, and confirm the tank is full before restoring power or fuel. Finally, perform functional testing by observing the heating cycle and checking for leaks or malfunctions to ensure safe, efficient operation.

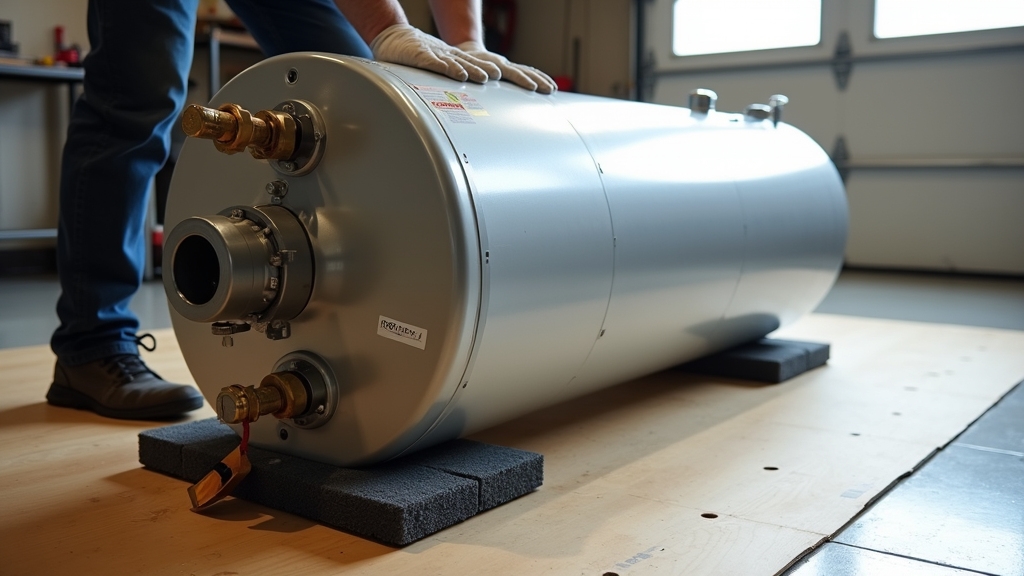

Proper Securing and Packaging Techniques for Safe Transport

After you’ve addressed the immediate steps following side transport, securing and packaging the water heater properly guarantees it remains safe during transit. Position the heater on a flat, stable surface, laying it on the side opposite the control panel if not upright.

Use ratchet straps or tie-downs to prevent shifting. Wrap the tank with thick blankets or foam padding, and protect vulnerable components like pipes and valves with corner guards. Cushion all sides to absorb shocks. Proper grounding procedures can also help protect sensitive components during transport.

Secure the heater tightly against movement using appropriate straps. Protect controls and piping by orienting the heater correctly. Employ thick padding and corner protectors for impact resistance. Avoid stacking items on or near the heater to prevent damage.

These techniques minimize mechanical stress and ensure safe delivery. Hiring professional moving services is recommended because they have the necessary equipment and expertise to transport water heaters safely and reduce the risk of damage.

Frequently Asked Questions

How Long Should a Water Heater Rest Upright Before Use After Side Transport?

You should let your water heater rest upright for at least 2 to 4 hours after side transport, though waiting up to 24 hours is ideal. This pause lets internal oils and gases settle, protecting heating elements and preventing damage.

Always place it on a level, stable surface, inspect for damage, and don’t power it on or fill it until the recommended rest time has fully elapsed to ensure safe, reliable operation.

Is Professional Help Recommended for Moving a Water Heater Sideways?

Yes, you should definitely seek professional help when moving a water heater sideways. Professionals use proper equipment and techniques to secure the unit, preventing internal damage and ensuring safety.

They understand how to minimize risks like component displacement and can advise on post-transport procedures to maintain functionality. Their expertise reduces injury risk, protects your appliance, and often includes insurance coverage, making the process safer and more reliable for you.

What Tools Are Best for Lifting a Water Heater Safely During Transport?

You want the right tools to prevent costly damage or injury. Use adjustable nylon lifting straps or padded slings rated for your water heater’s weight to distribute load evenly and protect surfaces.

Combine these with an appliance dolly equipped with secure straps and rubber tires for shock absorption. For stairs or heavy lifts, rely on electric stair climbers or hydraulic lifts operated by trained professionals.

How Does Side Transport Affect Water Heater Installation Compliance With Building Codes?

Side transport can jeopardize your water heater’s structural integrity, causing misalignment of venting components and damage to safety features. This often fails to meet required clearances and secure mounting per building codes.

You might face inspection failures due to improper access, ventilation, or damaged pressure relief valves. To guarantee compliance, always transport and install your water heater upright, preserving its factory conditions and safeguarding code adherence.

Treating Your Water Heater Like the Heart of Your Home

Transporting your water heater on its side is like steering a tightrope—one wrong move risks damaging delicate internal components. While sometimes unavoidable, you must handle it with care, securing it firmly and taking immediate steps afterward to prevent leaks or malfunctions.

Think of it as preserving the heart of your home’s hot water system; follow precise precautions and post-transport checks to ensure your heater runs smoothly and safely, no matter the journey.