Last Updated on April 26, 2025

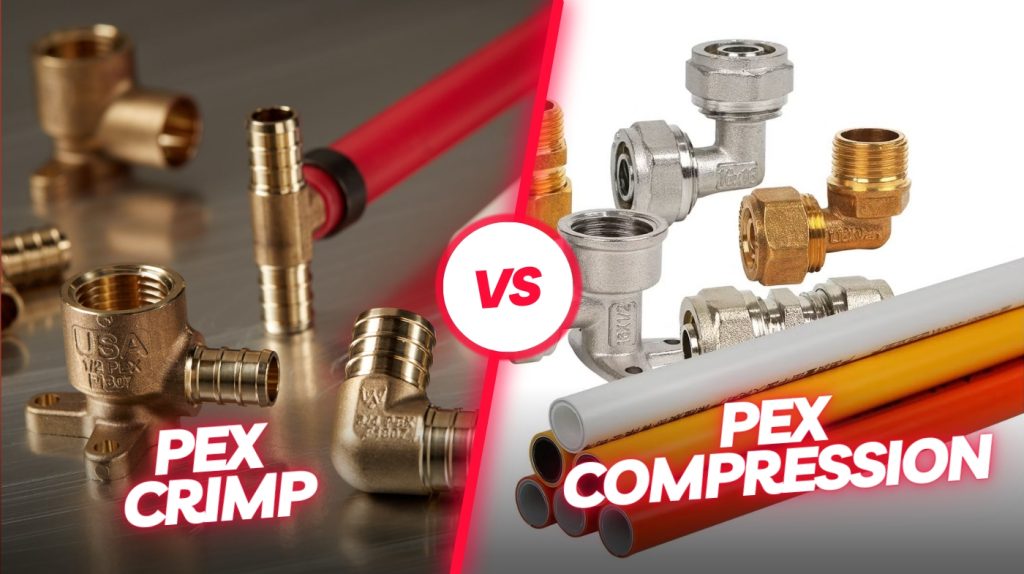

When choosing between PEX crimp and compression fittings, consider your project’s needs: crimp fittings use a metal ring and specialized tool for a permanent, cost-effective seal ideal for high-pressure systems.

Compression fittings rely on threaded brass components tightened with a wrench, offering reusability and easier repairs but at higher unit and tool costs.

Both provide reliable connections if installed properly. Understanding their differences helps you select the best fit for your project’s scope and longevity.

Key Takeaways

- Crimp fittings use a metal ring for permanent seals, while compression fittings use screw-tightened brass components for adjustable connections.

- Crimp fittings require a specialized crimping tool, whereas compression fittings can be installed with basic wrenches.

- Crimp fittings are cost-effective for large projects; compression fittings are pricier but suit DIY and repair work.

- Compression fittings allow disassembly and reuse, unlike the permanent seal of crimp fittings.

- Crimp fittings perform better in high-pressure applications; compression fittings offer long-term durability with proper maintenance.

PEX Crimp and Compression Fittings Overview

Although both PEX crimp and compression fittings serve to secure PEX tubing connections, they differ markedly in design and application.

Crimp fittings use a metal ring compressed around the tubing with a specialized tool, providing compact, permanent seals ideal for high-pressure and larger diameter pipes. Ensure that crimp rings are made from approved materials to maintain safety and compliance.

Crimp fittings create durable, permanent seals using a metal ring and specialized tool for high-pressure PEX connections.

Compression fittings, typically brass with a screw, band, and insert, clamp tubing without special tools and allow disassembly, making them versatile for repairs and connections to copper or CPVC pipes. They are known for ease of installation and versatility.

Crimp rings must match tubing type, while compression fittings accommodate various pipes, enhancing adaptability. Cost-wise, crimp fittings are cheaper but require a crimping tool upfront; compression fittings cost more but use common plumbing tools.

Installation Process and Tool Requirements

When installing PEX crimp fittings, you’ll need a calibrated crimping tool to compress the metal ring evenly around the tubing and fitting, guaranteeing a secure, leak-proof connection.

Position the crimp ring precisely over the fitting barb before applying uniform pressure with the tool. For PEX compression fittings, you can skip specialized tools and use basic wrenches to tighten the compression nut incrementally, avoiding overtightening.

Key installation points include:

- For crimp fittings: Slide ring onto tubing, fully insert fitting, then crimp evenly with calibrated tool.

- For compression fittings: Insert fitting with O-ring, hand-thread nut, then tighten with wrench until snug.

- Inspect crimps with a gauge or check compression and O-ring condition to guarantee seal integrity.

It is also critical to perform pressure testing after installation to ensure there are no leaks and the connections are securely sealed.

Cost Comparison and Project Impact

Understanding the installation requirements for PEX crimp and compression fittings sets the stage for evaluating their cost implications and project impact.

Crimp fittings generally cost less per unit and install faster, making them ideal for large-scale projects where labor time and tool investment pay off. They require a specialized crimping tool, and you’ll find crimp tools cheaper and simpler, but they require proper training to avoid errors.

Additionally, using the right PEX expansion tool can improve connection reliability and reduce installation time. Compression fittings, with higher unit and tool costs, simplify installation for less experienced users, reducing potential rework in small or DIY projects.

While compression components tend to be more durable, upfront expenses can be higher. Ultimately, your project’s scale, installer skill, and timeline dictate the cost-effectiveness of each system, balancing material and labor costs against potential downtime and repair risks.

Reliability, Durability, and Performance

Since both PEX crimp and compression fittings rely heavily on proper installation, their reliability hinges on correct technique and quality materials.

You must guarantee even crimp ring positioning and apply proper pressure for crimp fittings while using compliant O-rings and precision nuts in compression fittings. Compression fittings are also versatile for different PEX tubing types, which adds to their adaptability in various plumbing scenarios.

Proper installation also helps prevent issues related to pressure and flow restrictions, which can affect system performance. Consider these key points for reliability, durability, and performance:

- Compression fittings offer mechanical strength, reusability, and over 50 years of durability, plus adjustable sealing for precise fluid control.

- Crimp fittings create permanent, corrosion-prone seals that demand exact crimping tools and techniques for leak prevention.

- Both systems can restrict flow slightly; minimizing fittings and guaranteeing proper installation optimizes overall hydraulic performance and longevity.

Your choice depends on balancing permanent, fast crimps against adjustable, maintainable compression connections.

Best Use Cases and Practical Considerations

Although both PEX crimp and compression fittings serve similar plumbing functions, your choice depends on specific project demands such as tool availability, installation speed, and future maintenance needs.

If you prioritize quick, permanent installations in large-scale projects, crimp fittings provide cost-effective, durable connections once you invest in specialized tools.

However, note that crimp fittings are blamed for 99% of PB plumbing failures, which raises concerns about their long-term reliability in some applications. Their use often requires careful planning to avoid flow restrictions common with insert-style fittings.

Conversely, compression fittings require only basic wrenches, making them ideal for DIY, tight spaces, repairs, or renovations where disassembly or adjustments might be necessary. This flexibility is especially useful in scenarios where reusability and ease of maintenance are priorities.

Compression fittings’ reusability suits temporary setups, while crimp fittings excel in high-pressure, larger diameter lines due to consistent sealing. Keep in mind, compression fittings are pricier per unit but save startup costs by avoiding special tools.

Frequently Asked Questions

Can PEX Crimp and Compression Fittings Be Mixed in the Same Plumbing System?

You can mix different fitting types in the same plumbing system, but you need to guarantee they’re compatible with your PEX tubing and follow local plumbing codes.

Mixing crimp and compression fittings requires careful attention to material compatibility and installation quality to avoid leaks or failures. If you’re unsure, consulting a professional is wise to maintain system integrity and comply with regulations.

How Do Temperature Fluctuations Affect Crimp Versus Compression Fittings?

You’ll find temperature fluctuations cause PEX tubing to expand and contract, stressing all fittings. Crimp fittings create a permanent seal that resists loosening but need precise installation to handle this movement.

Compression fittings offer adjustability but may loosen over time as tubing shifts, requiring periodic retightening. Both types risk leaks or joint failure without proper allowances for thermal expansion, so you must design and install with temperature effects in mind for long-term reliability.

Are There Specific Brands Known for Higher Quality PEX Compression Fittings?

Like choosing a trusted compass in uncharted waters, you’ll want brands like Sioux Chief, Everflow, SharkBite, Viega, and TUBOMART for superior PEX compression fittings. These leaders offer lead-free brass, comply with ASTM standards, and provide reliable durability.

What Maintenance Is Required for Compression Fittings Over Time?

You need to inspect compression fittings regularly for wear, corrosion, and leaks. Check nuts and ferrules for damage or deformation, and guarantee proper alignment. Apply lubricants to threads and tighten fittings to the specified torque, avoiding overtightening.

Test for leaks under pressure and replace any faulty components promptly. Keep detailed maintenance records and schedule professional inspections for critical systems to guarantee long-term reliability and prevent failures.

Can Compression Fittings Be Used With Other Types of Tubing Besides PEX?

Imagine fitting a metal puzzle piece snugly onto a rigid pipe—compression fittings work similarly. Yes, you can use compression fittings with various tubing types like nylon, polypropylene, HDPE, and other hard or semi-rigid plastics.

They need a firm surface to compress against, so softer tubing like flexible PVC requires inserts or different fittings. This versatility makes compression fittings practical for many plumbing and fluid systems beyond just PEX tubing.

Know the Difference: Make the Right Connection

Choosing between PEX crimp and compression fittings is like selecting the right key for a lock each fits a specific purpose with precision. Crimp fittings offer speed and consistency, ideal for streamlined projects, while compression fittings provide versatility and reusability, suited for complex or repair work.

Understanding their strengths guarantees your plumbing system seals securely and performs reliably, releasing durability and efficiency tailored to your project’s unique demands.