Last Updated on June 1, 2025

You’ll choose a grinder pump if you need to pulverize solids for high-pressure, long-distance wastewater transport, especially in commercial or dense residential settings.

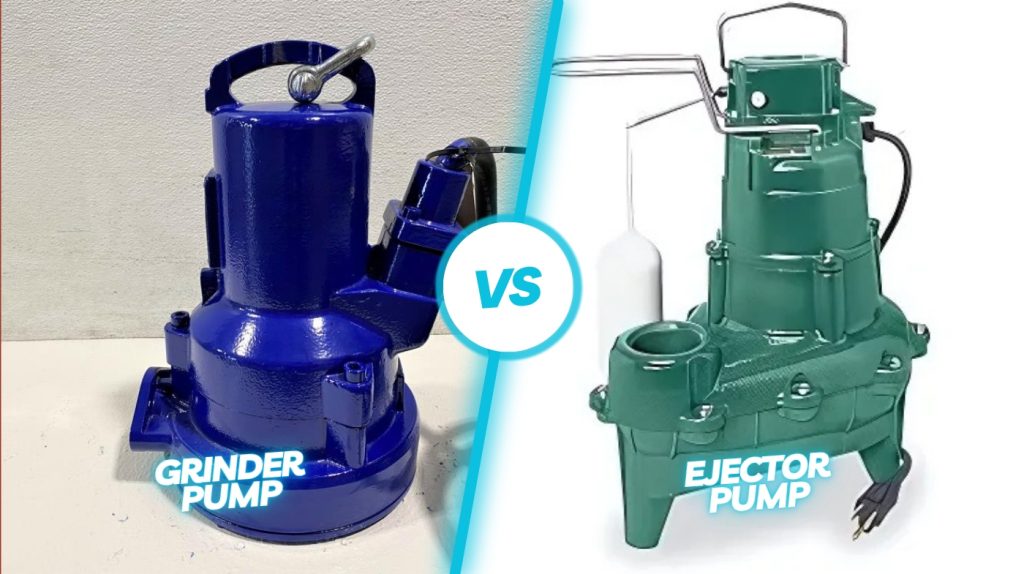

Grinder pumps are robust, have cutting mechanisms, and require more energy and maintenance. Ejector pumps, simpler and quieter, move unprocessed waste effectively over short distances and use less power with lower upfront and maintenance costs.

To optimize your system’s performance, understanding their design and application nuances is key for informed selection.

- Efficient Grinding Capability: This heavy duty grinder pump with stainless steel cutting blade can…

- Powerful & Durable: Quality stainless steel motor housing for high corrosion and abrasion…

- Auto Operation: Adjustable tether float switch allows the pump to auto turn on/off by water level in…

- 【Excellent Performance】1/2 HP submersible sewage pump with high-efficiency oil-filled split…

- 【Automatic and Manual Control】Automatic and manual functions are equipped with their own plugs…

- 【Durable and Safe】The mechanical seal has good wear resistance and is made of silicon carbide…

Key Takeaways

- Grinder pumps grind solids into slurry for clog prevention, ideal for heavy solid waste and long-distance pumping; ejector pumps move unprocessed wastewater.

- Grinder pumps cost more upfront ($2,000–$5,000) and require higher installation and maintenance than simpler, cheaper ejector pumps.

- Ejector pumps are quieter, use less energy, and need less maintenance, making them suitable for residential, low-solid wastewater applications.

- Grinder pumps feature cutting blades, bronze impellers, and alarms, while ejector pumps use lightweight materials without grinding components.

- Choose grinder pumps for commercial or industrial heavy solids; ejector pumps fit residential, short-distance, and gravity flow wastewater systems.

Definition and Primary Functions

Although both grinder pumps and ejector pumps serve to manage wastewater, they differ fundamentally in design and function. Grinder pumps incorporate a grinding mechanism that pulverizes solid waste into a fine slurry, ensuring unobstructed flow through pipes.

This grinding action is essential because it prevents pipe clogs and wastewater backups in homes. They activate once wastewater reaches a specific tank level.

You’ll find them ideal in residential or commercial settings where wastewater must be elevated to main sewer lines, especially in low-lying areas prone to clogging. They are typically more efficient in handling wastewater with solids compared to pumps without such mechanisms.

In contrast, ejector pumps focus solely on lifting wastewater without grinding solids, relying on vacuum or pressure to move fluid. They’re commonly installed in basements to handle wastewater from sinks and toilets, offering a cost-effective solution where solid waste grinding isn’t necessary.

Understanding these distinctions helps you select the appropriate pump based on flow rate and site requirements.

Design and Key Components

When selecting between grinder and ejector pumps, you must understand their distinct designs and key components, as these directly impact performance and maintenance.

Grinder pumps feature cutting mechanisms that macerate solids, bronze impellers for durability, and corrosion-resistant stainless steel housings. They require more power and can be installed deeper due to their robust design.

The E/One Extreme Series grinder pump, for example, utilizes a unique progressing cavity design that enhances durability and efficiency. Proper maintenance, including disassembly procedures, is essential to ensure their long-term functionality.

Ejector pumps, by contrast, rely on pressure without cutters, use lighter materials like PVC, and demand less power and maintenance.

Consider these critical design elements:

- Grinder pumps’ guide rail mounting simplifies maintenance, easing access and service.

- Control panels with alarms ensure operational monitoring, especially for grinders.

- Material choice directly affects lifespan and resistance to corrosion.

Operational Capabilities and Differences

Understanding the operational capabilities of grinder and ejector pumps is essential for selecting the right solution based on waste type and system demands.

Grinder pumps use rotating blades to shred solid waste into smaller particles, preventing clogs and enabling efficient transport in systems with high solid content.

In contrast, ejector pumps rely on impellers to move mixed wastewater without grinding, making them suitable for residential applications with low solid waste.

Sewage grinder pumps are designed for high pressure/low volume applications, making them ideal when pumping to pressurized city sewer mains or over long distances. Their power demands often require careful consideration of energy consumption to ensure reliable operation.

Grinder pumps excel in commercial or industrial settings due to their ability to handle diverse debris but require more maintenance because of blade wear. Ejector pumps are simpler, quieter, and generally need less upkeep.

Both pumps integrate into sewage systems, yet their fundamental difference lies in waste processing—grinders actively reduce solids, while ejectors move raw sewage unprocessed.

Energy Consumption and Efficiency

You’ll notice grinder pumps generally consume more power upfront due to higher horsepower and startup current compared to ejector pumps. However, their operational efficiency often reduces energy usage over time by effectively handling solids and minimizing clogs.

Evaluating these factors helps you understand the cost implications tied to both energy consumption and maintenance. Proper maintenance and care routines are essential to sustain this efficiency and prevent premature pump failure.

Consider that the actual power draw may be significantly lower than the rated wattage due to motor and pump efficiencies as well as operating conditions such as head and flow efficiency factors.

Power Usage Comparison

Although grinder pumps typically draw more power due to their higher horsepower ratings starting around 1 hp (746 watts), they can operate more efficiently over time compared to ejector pumps, depending on usage patterns and system design.

Proper pump selection based on flow rate and head pressure is essential to ensure optimal efficiency. You should consider that grinder pumps often run for shorter intervals but with higher power, whereas ejector pumps operate longer at lower wattage.

This impacts total energy consumption and cost-effectiveness differently. When comparing power usage, keep in mind:

- Grinder pumps consume between 9 and 20 kWh monthly, potentially increasing your energy bills.

- Ejector pumps use less power but may run longer, affecting efficiency.

- Your system’s design and water usage heavily influence which pump minimizes energy costs.

- Typical grinder pump operation involves running for 10-30 minutes daily in multiple short cycles, which helps maintain system efficiency.

Efficiency in Operation

When selecting between grinder and ejector pumps, you must weigh their operational efficiency and energy consumption carefully. Grinder pumps consume more energy due to their higher horsepower and continuous grinding action but excel in handling solid waste efficiently.

Ejector pumps use less energy by pumping without grinding but may face efficiency losses from solids accumulation. Cleaner pumps operate more efficiently and last longer when calcium buildup is removed regularly through maintenance techniques.

Grinder pumps enable easier passage of wastewater by reducing solid size, which improves overall flow and reduces clogging risks in the system (waste size reduction).

| spect | Grinder Pump |

|---|---|

| Energy Use | Higher (≥1 HP, continuous grinding) |

| Waste Handling | Breaks solids; smoother flow |

| Maintenance Impact | Requires regular upkeep for clogs |

| Application Suitability | Best for high-solid environments |

| Aspect | Ejector Pump |

| Energy Use | Lower; no grinding required |

| Waste Handling | Moves solids; no size reduction |

| Maintenance Impact | Simpler, less frequent maintenance |

| Application Suitability | Ideal for low-solid wastewater |

Maintenance Requirements and Challenges

Since grinder pumps involve complex components like blades, seals, and alarm systems, their maintenance demands more frequent and specialized attention than ejector pumps.

You’ll need professional inspections annually and routine checks every three to five years, focusing on blade sharpness, seal integrity, oil contamination, and alarm functionality.

Running the pump quarterly prevents operational issues. Challenges include blade dulling, clogging, and alarm reliability, requiring prompt repairs to avoid overheating and failure.

Access and safety precautions, such as power shutoff, complicate service. In contrast, ejector pumps require simpler upkeep mainly motor operation checks and debris clearing from impellers and discharge lines—with fewer complex components.

Ensuring timely maintenance can help prevent potential water damage and extend the lifespan of your pump system.

Suitable Applications and Environmental Factors

Since grinder pumps excel at handling heavy-duty waste and maintaining pressurized systems, they suit commercial and high-elevation applications where long-distance pumping is required.

You’ll find them ideal for restaurants, hotels, or any setting needing reliable waste transport over thousands of feet, often through small-diameter pipes. Grinder pumps are designed for high pressure, low volume transfer over longer distances, making them optimal for pressurized sewer mains.

Grinder pumps are perfect for commercial settings needing long-distance, high-pressure waste pumping through small pipes. However, their grinding action increases noise and energy consumption and demands regular maintenance.

In contrast, ejector pumps fit residential or short-distance applications with gravity flow, offering quieter, more energy-efficient operation and simpler upkeep. Consider these factors when evaluating suitability:

- Need for high-pressure, long-distance pumping versus short, gravity-assisted flow

- Volume and type of waste—heavy solids or lighter residential sewage

- Environmental impact, balancing operational noise and energy use against reliability and clog prevention

Selection Guidelines and Compatibility Factors

To select the appropriate pump type, you must evaluate key factors such as location, waste characteristics, and system requirements.

If your installation involves pumping from lower elevations or below main drain lines, ejector pumps suit better due to their high-volume, low-pressure capacity and lower noise.

These pumps are often used in basement bathrooms and septic systems, carrying away waste, sludge, and toxic materials to septic or city systems, and they require vent pipes to remove gases and odors produced during waste transport.

Conversely, grinder pumps effectively handle solid waste through their grinding mechanisms but demand more maintenance and higher upfront costs. Consider the waste volume and required horsepower to ensure adequate flow and vertical lift.

Automatic grinder pumps simplify control but add complexity, while ejector pumps save space and reduce operational noise. Budget planning should weigh initial investments against long-term maintenance expenses.

Frequently Asked Questions

Can Grinder Pumps Handle Grease and Oil Better Than Ejector Pumps?

You should know that grease and oil cause about 60% of pump clogs. Grinder pumps handle these substances better because their rotating cutting mechanism breaks down solid waste and can partially manage grease and oil, reducing blockages.

However, their effectiveness depends on design and maintenance. Ejector pumps lack grinding features, making them less capable with greasy materials. Regular upkeep is essential to maintain efficiency and prevent clogging in both types.

What Noise Levels Can I Expect From Grinder Versus Ejector Pumps?

You can expect grinder pumps to operate around 60–70 dB, comparable to a normal conversation or washing machine noise, running briefly with a low hum.

Ejector pumps tend to be louder, typically between 70–85 dB, similar to a blender or dishwasher, with a steadier mechanical hum. Noise varies by installation materials and environment; placing pumps on rubber mats can reduce sound, while hard surfaces may amplify it.

Are There Specific Brands Known for Reliable Grinder or Ejector Pumps?

You’ll find Liberty Pumps and Zoeller excel in both grinder and ejector pumps, known for reliability and quality engineering. For grinders, Little Giant and Saniflo stand out with superior grinding mechanisms, while Franklin Electric backs innovative designs.

Ejector pumps also benefit from Wayne and Burcam’s offerings, though less prominent. Choosing these brands guarantees you get durable, efficient pumps suited for demanding wastewater handling needs in various settings.

How Do Grinder Pumps Affect Sewer Odor Compared to Ejector Pumps?

You’ll find that grinder pumps reduce sewer odor more effectively by finely shredding solids, limiting anaerobic conditions that produce smells. They maintain consistent flow and pressure, preventing stagnation and debris buildup.

Ejector pumps, lacking grinding action, can leave larger waste pieces that cause clogs and odors. So, if odor control is critical, relying on grinder pumps offers a more efficient waste breakdown and odor mitigation strategy.

Can Grinder Pumps Be Retrofitted Into Existing Ejector Pump Systems?

Yes, you can retrofit grinder pumps into existing ejector pump basins, provided the basin size and configuration meet industry standards like the 24-inch models from Liberty or Zoeller.

Retrofit kits often include compatible lids and integrate with existing piping and electrical systems. However, you must verify electrical specs, discharge pipe compatibility, and hydraulic requirements to guarantee seamless performance and avoid operational issues during installation or use.

Distance and Pressure: Matching the Right Pump to the Job

When choosing between a grinder pump and an ejector pump, you can’t afford to overlook their distinct operational nuances and maintenance demands. Grinder pumps excel in handling solids, while ejector pumps offer simplicity and lower energy use.

Your decision should align with your system’s specific needs and environmental factors. Picking the wrong pump could feel like trying to fit a square peg in a round hole, so analyze compatibility carefully to make certain of peak performance and cost efficiency.

- Heavy cast iron construction

- 115V single phase

- Patented V-Slice cutter technology

- 💧EXCELLENT PERFORMANCE: FavorCOOL 3/4HP submersible sewage pump elevates water to a maximum of…

- 💧TOUGH AND DURABLE: This heavy-duty basement sump pump is constructed with a rugged cast iron…

- 💧CHOOSE HOW IT RUNS: An adjustable mechanical float switch automatically turns on/off the pump…

Last update on 2026-02-22 / Affiliate links / Images from Amazon Product Advertising API